Today the whole spindle assembly dropped onto the baseplate - CLUNK!

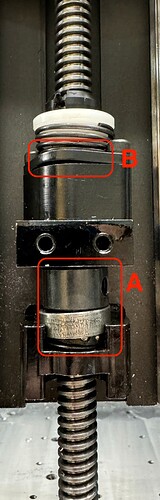

I disassembled the z-axis assembly - it seems like area labelled [A] in the photo is what is supposed to hold the weight of the whole spindle assembly. If it fails (which it did), the spindle weight all gets transferred to the z-axis stepper coupler, which isn’t meant to hold much of an axial load and eventually loses grip.

Also, the area labelled [B] in the photo seems suspect, like it’s bent.

I’ll contact support directly, but my question for the forum is: what do you call both areas [A] and [B]? If I knew the nomenclature I’d probably be able to describe this stuff more clearly.

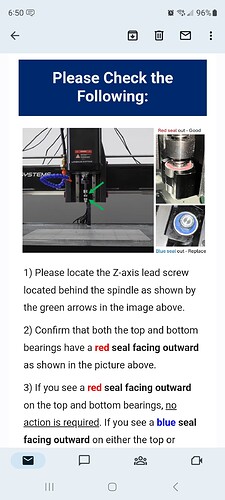

Are your bearings for the Z axis backwards? LS just sent out an email to everyone who bought a machine since Dec noting that some of them could have bearings with the blue sheild facng out, which is incorrect. I looked at some pictures I took of mine and noticed that it had been built that way. They have already entered an order to send me a pair of new ones. I only have 2 or three hours of machining time on mine, so i havent noticed any slop or problems yet.

I dont know if that can lead to your problem or not, but it sounds likely?

The blue side was facing up, which I think is correct?

The setscrew in the collar (I think that’s what it’s called) seems to have been stripped/ground off, and the plate that the assembly is mounted onto has signs of rubbing as well - see pictures, I’m not describing very well.

In any event, LS is sending me a new leadscrew assembly.

If the upper bearing had the blue seal facing up and the lower bearing had the blue seal facing down, the bearings were backwards. I havent opened one, but i assume they are angular contact bearings.

Again, this is something that they think only affects Z assemblies from Dec 2023 on.

ok, yeah so my upper bearing was indeed backward. I ordered mine in March 2024.

My upper one was backwards too, my lower was correct. I ordered it around the same time as you. Just an assembly line screw up, looks like.

1 Like

I got my repair kit in the mail yesterday. It was a single bearing and a lock nut. I swapped out the bad bearing, reused the good one, and put it back together with the same lower z axis shims.

I took the old bearing apart to see if any damage had occurred and i didnt notice anything unusual, but i only have a few hours of machine time so far and no 3D profiling, just simple parts.

2 Likes

I got mine a few days ago - leadscrew, 2 bearings, as well as a nut (not locknut) that doesn’t fit the z axis threading… I assume that was a mistake.

Everything seems to be working fine now.