How are people doing softjaws on the low profile vise? Want to start making things…

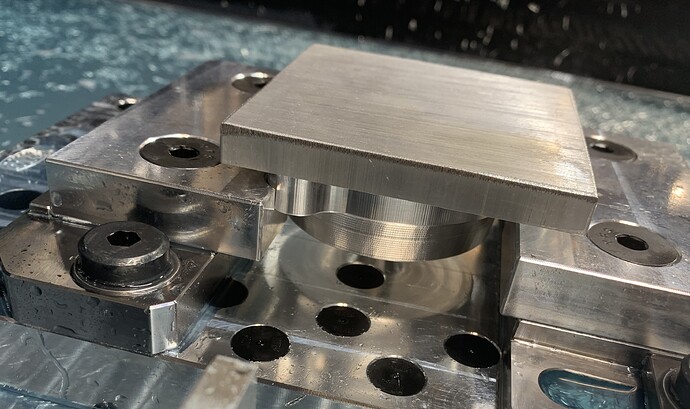

Airplane wheel cap is looking good.

Looks great! How do you tighten the vice? I made a set a while back but only replace the front of the jaws.

I just followed the video directions on SMW website. Seemed to work fine so far.

Looks great. I’m referring to the langmuir vise though. I opted not to get the SMY setup based on previous experiences. It gets the job done but is time consuming.

Langmuir- are you guys planning on making soft jaws available for your vise? Maybe sell new hard jaws with threaded holes to accept soft jaws?

yea, i would love some softjaws for the langmuir vise since my first cut i hit the damn harden jaws lol

I had the same thing happen last weekend. I was cutting a part out of aluminum and for some reason the end mill pulled down. The collet was tight and it didn’t spin in the collet, so I think there must have been some debris in there or something.

Did the same thing one of my first few cuts, went from a 3/8 to 1/2 end mill and forgot to run the tool set. Thankfully only took out about 1/8 on the center back to jaw.

I am all new to this so I need to ask.

What exactly is a soft jaw and what are the reasons to use it?

Thanks,

Sbdon

A custom vise jaw made out of a material that is softer than your workpiece (instead of the usual hardened steel jaws machine vises are usually). You will often see them machined to match the profile of a round part, so that the can grip an in-progress workpiece and not marr the surface.

You still want rigidity, so soft jaws for steel parts are often aluminum, and soft jaws for aluminum might also be (a softer alloy of) aluminum, or hard plastic. Soft jaws for plastic parts might be made of soft plastic or rubber, and so on.

Very helpful. Thank you.

Sbdon