Hi All,

Sorry that we have not responded to this thread sooner. Behind the scenes we have been steadily tracking this issue and are working swiftly toward a resolution. While I can’t go into specifics yet, I want each of our customers that have purchased a water table to know that you are going to be taken care of. If you’re water table develops a leak, please let us know ASAP.

3 Likes

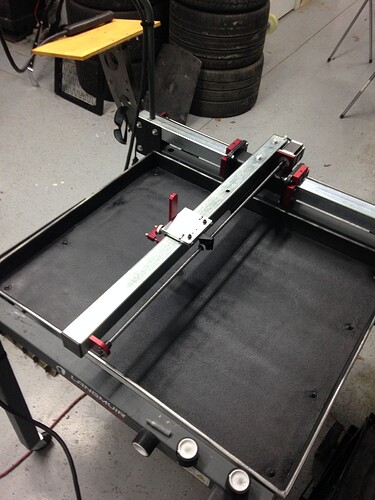

I noticed that too, not really pitting but some good and stuck on debris, that takes a good scrubbing to get off. Richard Horn was by today and noticed I have a thin rubber mat in the bottom of the tank (between the two slat rails). It makes it real easy to just lift up and bust up the debris once it dries over night. Nothing building up underneath either. or corrosion. I also don’t leave the mix (+8.5ph) in the table for more than a few days if I’m not using.

Mirage2991, have you checked the ph of mixed water?

I have not checked the Ph of the water. I can’t stress enough though that the sides of the water tray even though they were submerged have no signs of pitting…no signs of anything other than a light tan appearance that I can almost wipe off with a rag.

My table looks woorst than EdS’s picture above…I put some Navel jelly to see if it would help, didn’t do much, does clean the alum really well though, but nothing for the stuck on particulates…

I think EdS is nailing it with Galvanic corrosion. Because this is happening at the bottom of the tray, and not the side, this is pointing out being Galvanic corrosion, which I’m not sure how you’d mitigate other than emptying and cleaning…at this point, one would have to wonder if we would have been better off staying with a steel tray.

The slats (steel) look great, little to no rust…no pitting.

I’ll take up my mat tomorrow and give it good wipe down to see if there is pitting occurring and get back to you. I do keep the anode clean and don’t allow much build up. I also don’t ground through the pan, but not sure that is a factor here though. Another thing to add, you really do need to have a proper ph if not running straight water. I also would think that the oxide film on the aluminum is doing better to protect it than cleaning it back to bright with a caustic and re exposing it to the atmosphere.

Best, Steve.

yea the Navel jelly was to try and see if it would help loosen the metal globs stuck on it, not an attempt to make it shinny again

I can see the ph being a factor but i don’t see it stop galvanic corrosion though. My neighboor works at a shipyard (as in Maersk ship types) i will ask him for advice… though i halfway expect him to say “don’t put metal in contact with alum in a water environment”… would explain that your matt idea may help or even solve it…

Got me so interested, I went out and pull up the mat. lol.

The gray coating is smooth and looks like the same as on the side of my dads AL fishing boat or my buddies pontoon (that he spent a month polishing on). slight_smile:

It looks ok under there with no pitting or the appearance of it breaking down. I chose the mat just because it’s much easier to vacuum out the junk. Kinda amazed or bewildered by the super fine brown dust that builds up.

That’s why you wear a respirator when cutting by hand  The stuff settles in the water table instead of going all airborne. It’s the residue that was the sparks coming out the bottom of the cut (burning microfine particultaes of metal).

The stuff settles in the water table instead of going all airborne. It’s the residue that was the sparks coming out the bottom of the cut (burning microfine particultaes of metal).

Flex Seal is a rubberized spray used for sealing leaks and such and a good coating should stop the pitting and any leaks. But you’d need to ground to the material or the slats since the tray’s metal surface will be insulated now.

1 Like

i too though of spraying some

flex-seal in the tray. Might just pick up a can and give it a go!

1 Like

My Home Depot has it on sale - something like $12 a can. They have both the black & clear(ish) kinds. You’ll see there’s a coating on the tray with the clear but it looks sort of aluminy.

side of water tray, no pitting, while bottom shows embeded steel (brown). This is the corner i do all my cutting from

opposite side cornere where i never cut

!

Is that with straight water or a sodium carbonate mixture? If you are adding the sodium (Borax washing soda) the ph is not high enough and it’s acidic (rust on the coated tek screws). I use a cheap pool test kit from Walmart to check it. While i haven’t had any issues with the Borax mix, I have ordered the liter of Green Cut and plan to use it a majority of the time.

Where did you find a liter? I usually see it in 5 gal buckets (or 8 1L bottles).

after using a cleaning wheel, same places as above, the steel will come off, pitting is left behind. The sides have little to none.

1/4 cup for 7 gal was my mix ratio.

i have a can of bed coating i will be spraying onto it to mitigate the issue for now.

Straight water it is, and dumping it after use. Table was in water for 6 days, then 4 days dry, then 6 days again. Total cut time probably 5min.

So did I James. I went to the link above in this thread and they have it in the 5 and 1 liter. Looks to be 2 liters for our sized tables. Wasn’t impressed with the shipping so I combined an order with a local friend who also has a table.

I think you have a mixture issue there sir. I have the table filled for over a week, then drained and cleaned to sit for a another week, then filled and left it for a another week to 10 days. Only cutting steel so far but there is no rust anywhere in the table, not even the swarf that is laying in the mat is rusty when I vacuum it out.

all done. Drying out for 24h now.

2 Likes

Very nice man! Bet that will be the solution for sure.

I’m sure you are onto something with the Ph as well as having a mat which helps against galvanic corrosion. With my tray already pitting, I didn’t want to risk it. I have no idea how the canned sprayed bed liner will do (Lowe’s was out of flex-seal spray on). I also thought that Rhino lining the inside of the pan could be a good, long term alternative. With such a small area it shouldn’t cost much to have it done. Some to think about for next time!

2 Likes

That’s a good idea too. I looked for an epoxy coating when I found the Flex Seal spray at HD. The Lowes I was at tonight didn’t have the spray but they had it in qt and gallon cans that can be brushed on.

I have gotten both in Amazon as well. I use the clear to seal acrylic custom shaped terrariums and planters I make on the laser.

1 Like

i thought of POR15 too… might work, i have some but it’s not cheap and i need what i have left for the hotrods. Might use some on a piece of metal and submerge it in the tray to see how it does.

1 Like