So I’ve been playing with my pro a decent bit now and I can’t seem to get rid of my beveled edge problem.

I running the RW45 that came with the pro. I have new tips. It seems to bevel the most when running horizontally along X and when moving down Y. The bevel is always the same direction which makes me think it isn’t my torch alignment. I’m running a dessicant drier at the compressor and another at the RW. I’m using a 50’ rubber hose (maybe my problem?).

I’ve played with tons of amps/ipm/TH settings and nothing seems to really change the bevel.

I’m begining to think maybe the amount of bevel I’m getting is just normal? It’s not horrible, but not great at the same time.

I’m also noticing my TH isn’t staying steady at .0625. I can see it rise periodically in the middle of cuts to probably close to 1/8 and maybe even 1/4. I have the THC on and voltage seems to stay steady. Not sure what’s going on there.

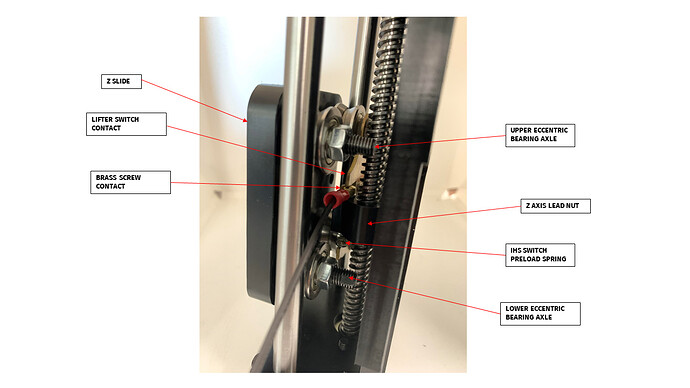

I noticed on mine the eccentric bearing axles werent adjusted properly. I had some slack on the bottom one. It fixed most of my bevel. It was causing the Z slide to tilt the slightest bit. To adjust loosen the nut and the eccentric axle is oblong. Turn the axle until you get the right tension and then tighten the nut. Only adjustable on the right side. Left side is fixed. Also if using a hand torch it is really easy for it to be tilted.

1 Like

Thanks for the tip. I checked that a while back and it didn’t make a difference. I’ll check it again though.

1 Like

Which torch are you using? We saw a lot of bevel issues with the only style torch which is why we pushed Razorweld to supply these machines with the X45 torch from the factory which uses Hypertherm style consumables.

I’m using the X45 torch and factory consumables. I got the consumables from a member here who sells on eBay (forgot his name).

I was finally able to flash the new firmware. That helped a tiny bit as I notice the torch stays constant height now. I may try to lower my TH to something like .055 instead of the .0625 I’ve been using. I also probably need to switch out consumables since before the THC firmware the torch was rising to around 1/4 on some cuts which probably ruined it even though I only did one cut.

Also make sure that you have clean dry air- makes a big difference.

I’m using two desiccant driers and I live in the desert, so hopefully I’m getting somewhat dry air. Other than buying a 2k drier, I think I have to deal with what I’ve got. I’ve managed to get the cuts a bit better, but still not perfect. The update to the THC helped with the torch rising and destroying consumables super quickly. I think I now need to start over playing with speeds and amps to since I was likely getting bad results before with the height raising mid cut. We’ll see.

Did you fix the bevel problem?

Sort of. I had to set sheetcam height to something like .020. With that setting, it physically looks much closer to .06 when cutting. Before, with sheetcam at .06, it physically looked way too high.

Idk if it’s a sheetcam issue or a fire control issue, but that’s the only way I’ve been able to tame the bevel.