What’s everybody’s experience with cutting small stencil lettering in .135 thick, low carbon steel. The smallest letter I’m trying to cut is .3 and all I’m doing is blowing out the whole inside of the letter. Any help would be appreciated, including settings. Thanks!!

.3 tall? That’s tiny.

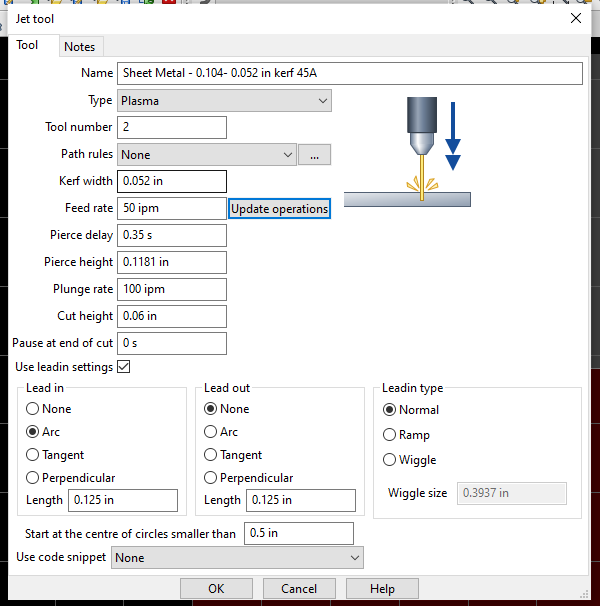

Post what your lead in settings are or a screenshot of them. What software are you using?

Fusion 360. I had it set the lead in’s down to 0.01 because it would not process through going any arger than that because of the small tails of the lettering. I will have to get you a screenshot later this evening. Thanks!

That size font seems almost too small to cut. Especially letters like a, e, d, b, o letters that have inside geometry that needs to remain.

I can’t disagree, but I just wanted to see if anyone had any experience or luck with lettering this small. A gentlemen i know did a sample on a waterjet and he was able to succeed, which shocked me. Didn’t know if this machine was capable of pulling that measure. Thanks!!!

Of the three laser, water jet and plasma, plasma is at the bottom of the list for detail and quality.

I’m surprised you were even able to get fusion to generate a tool path for those small letters

I cut a John Deere logo that the letters were 0.75 and that was probably as good as I could do any smaller and the spaces would have burned through.

Would that be with fine cut consumables?

RW45 standard tip.

I cut some at .7" with a tip rated for 60 amps. They had cutouts, but it was kind of a bold font.

You’ll likely just have to try it because your minimum is going to depend on font, kerf, tip, etc.

You could experiment with single line text numbers. I have found that you need at least 0.125 inches (preferably 0.15 inches) for the lines to survive. If you want the stencil look, I think 0.7 inches tall might be reaching the limit. I just know when I create bridges to hold the centers of letters and numbers, 0.125 inches sometimes works but looks very fragile (risks getting burned out and the center falls out.)

New user here, but I will offer my 0.02.

I am not sure what your application will allow. I was able to use a normal tip and cut 0.375" tall letters. I used Solidworks single line font and had SheetCam perform a center cut. I was just making some chamfer gauges for myself, so I was OK with missing the inside of a 4.

If you are trying to do something decorative that could be a challenge.

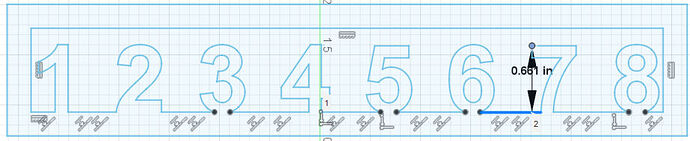

So based on others suggestions and my experience with 0.125 inches being close to the limit of surviving a burn on both sides I did a quick sketch of numbers with the the numbers merged with the body. It turns out the the height was close to 0.75 that @SWomack and 0.7 that @Wsidr1

accomplished. In this example, the number stands proud as it is part of the body. The center is free to fall out.

I used Arial Bold for the font.

Here is what the body would look like:

Agree with you @HooverAZ, if you don’t mind losing the middle then you can go smaller but if you imply “stencil” that would mean there is an intention of preserving the center. And yes, I would say single line text would give you a shot at smaller but there are still going to be sacrifices to the the closed loops in some numbers.

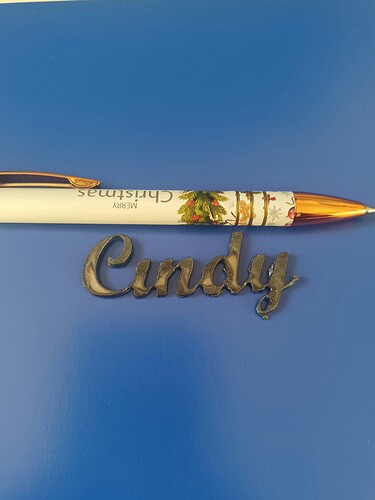

looks great for stainless. time for a die filer!

20 ga stainless. Single line font in bottom. Needed just a little longer on the pierce delay. Was about the same height as a quarter.

Tall letters on the cards are .351" tall and the short letters are .234" tall any smaller it seems that things start to vaporize. The card is 14 ga.

I should try again with 20 ga too.

.75 is the smallest i can cut letters. Razor weld 45 regular tip

Script text is the most difficult because of the wide variation in segment width.