Unsure if this is a job anyone would care to do on an MR-1 since I don’t know a single machinist anywhere.

Looking for some 4130/4140 machined as such

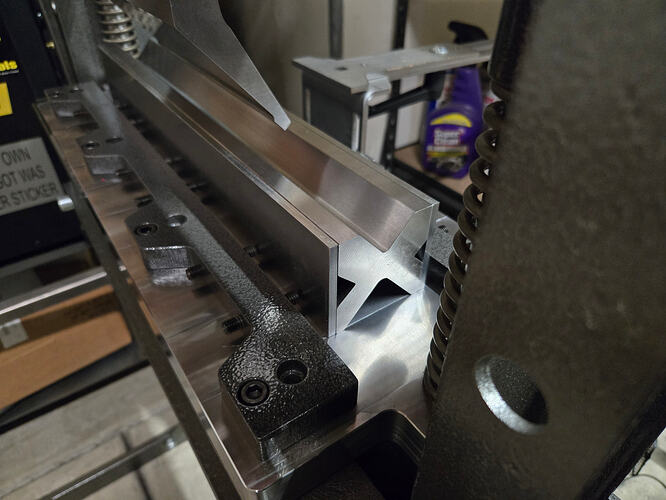

2.35” tall, 16” wide, anywhere between 0.187” thick to 0.25” thick (whatever someone may have on hand).

I can buy 18” long pieces of a similar material, ground flat to +/- 0.002” from McMaster Carr but at 2.5” tall for $75 each. I need two.

If someone can/will do this for similar but at the height requested, would love to skip McMaster Carr.

Brake Shims Machined.step (10.1 KB)

Speedy Metals 1/4" x 2-1/2" 4140 Alloy Flat https://share.google/6lHssaKkhqKdq7xdN

You can cut that down and it should be what you need much cheaper.

So just skip the surfaces being flat and even?

I was just wanting something that’s even all the way around in terms of thickness for safety.

I don’t know how critical a machine surface is for your brake shims. You had a pretty big tolerance on the thickness so if that’s the case you could get really close to what you need with a tape measure for length and a cut off wheel with guide for the width. Just a suggestion for you to do it yourself and save a lot of money. Especially if you need more of them down the road.

1 Like

Ah gotcha.

So where the tolerance is important to me is at least one side of each 16” length. I’d like it to be “pretty flat” which could mean anything but ideally whatever someone can get done on a mill. This finished side will contact my 4-way die evenly on the top and bottom flat surface between the die opening.

Same for the opposing side.

Plus outsourcing the job would mean they could mill down the height to my specified 2.35” tall, which is within a hundredth of a standard die (60mm or 2.362”).

I don’t mind paying more, which is why McMaster Carr is an option since it’s ground flat, but I would still need to shave off each edge for that difference of 2.5” to 2.35” and it’d be done with an angle grinder (not ideal for me).

Thank you again @Richarddbeck83

Came out exactly as requested; I wanted a height difference of 0.01” to allow material to sit only on the die and not the shim.

2 Likes

Happy to have helped out!

2 Likes