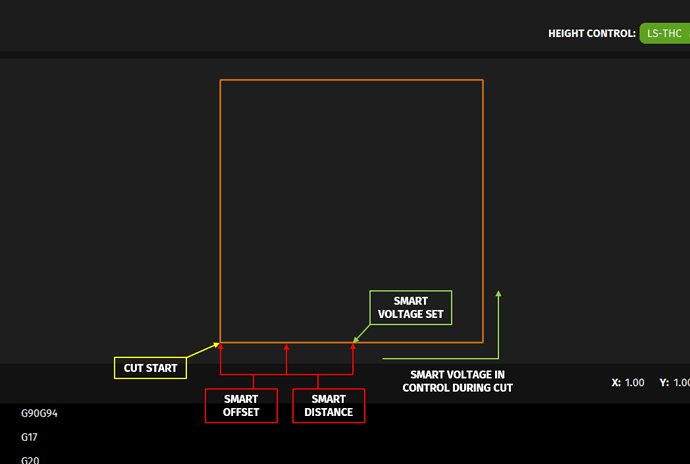

Typically a lead-in is too short for the THC to figure out what voltage it wants to use and then apply it to the cut before the lead ends already done.

Using smart voltage you would have to have a lead in that was over a quarter inch long and into the material for it to register the voltage and then apply it.

I sure wish I had a spare electronics enclosure I could hook to my office computer so it trick fire control into thinking it was hooked up to a machine. Then I could explore and screenshot these options with ease and run dry runs.

@langmuirsystems you have any mostly working electronic enclosures you could sell a guy?

This goes into the how and why the THC works

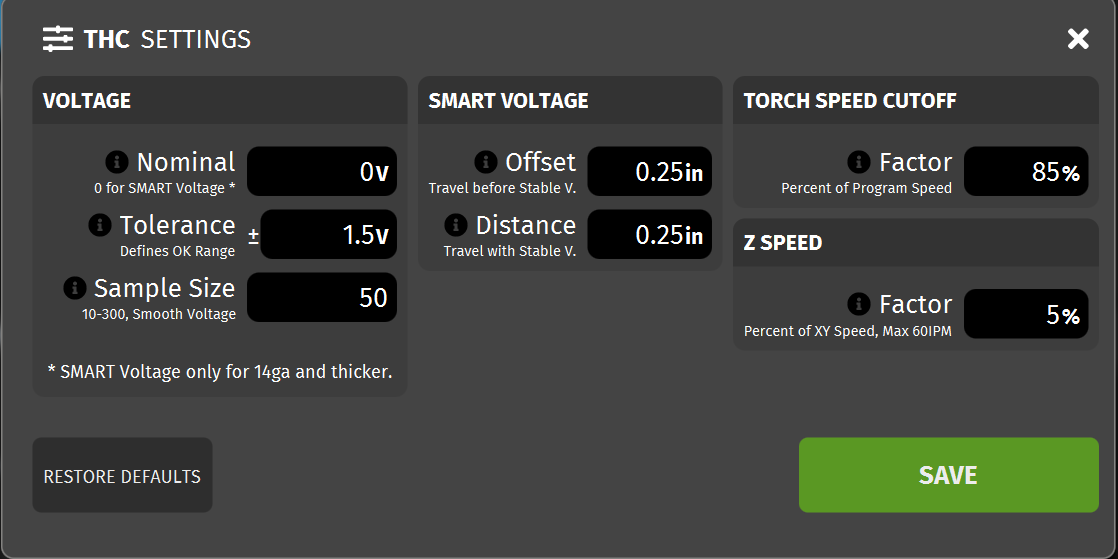

This is the menu inside fire control

So if you set your smart offset long enough so it we’re sure the torch was in the material then you may be able to have it used torch height control from that point on.

I have a PowerMax 85 so it’s not often I get into Edge start territory.