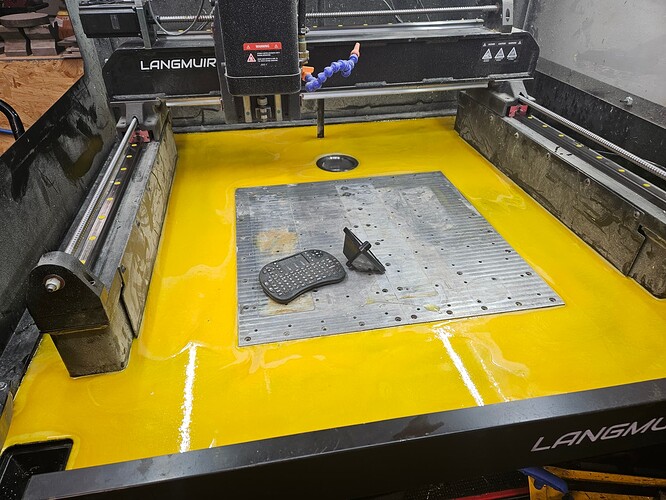

Has anyone had to repour their epoxy coat after they had been using the mill with coolant? My epoxy never seemed to get rock hard, can gouge with a fingernail. Today I was cleaning up and one of my corner drains came right out. Thinking of putting in a larger drain and repouring the epoxy coat. Thoughts?

you will have to scuff sand the epoxy with 100 grit so it grabs it. Might be worth it to just do a few heavy coats of Flex Seal or Rustoleum Oil based enamel.

That suggests a bad mix - incorrect proportions of catalyst & epoxy. It will never harden.

The correct way to fix it is to chisel out the soft epoxy and replace it with a new pour mixed correctly.

People do halfway decent repairs of failed epoxy pours by sanding or grinding the surface and pouring a clean properly mixed layer on top but that can result in a higher surface than you want and you’ll always have the weak soft layer inside. That may not impact your use although I haven’t seen anyone reporting long term results here, the recommendation is typically to remove & re-pour.

I agree with @jamesdhatch. Just bite the bullet and start removing it. Make sure you mix that stuff with a drill paint mixer. Mix it, then remix it. All the bubbles will come out with the heat gun. Also, ensure the color agent is compatible with the epoxy you use.

Good job. Mix and mix again, agreed ![]()

Nice. Make sure you scrape down the sides of the bucket when you’re mixing.

I have the same issue. I know I mixed it right, but was very cold the day I poured. I used heaters, but the epoxy never got rock hard. I was wondering if I just scraped off the surface would be good enough.