Have you tried to contact razor well directly their office is in Washington and their phone numbers on the back cover of your manual.

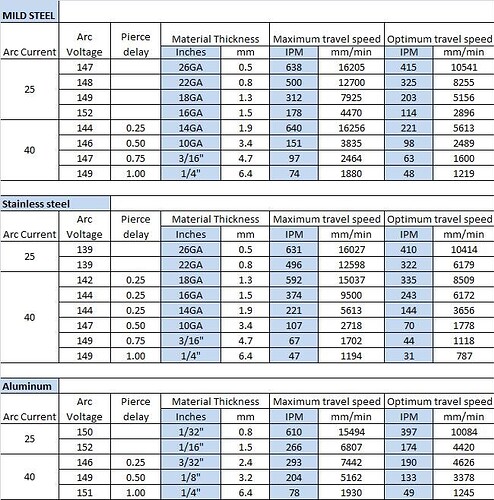

This is a cut chart that was provided directly from razor weld and has been posted to this website several times over the years.

Razor weld does get the job done but depending on what torch is mounted to it and what table it’s on and how your air pressure set up and considering they don’t grade any of the components by tolerances before they’re installed on their pcbs, there’s quite a bit of variance between machine and set.

All these cut charts are a good start but your particular situation will be slightly different.

Company’s offering plasma torches that have highly graded components and very tight tolerances can offer cut charts because one of their machines is going to act very similar to another.

Machines like the razor weld which are built on the premise as being as cost-effective as possible while providing the minimal amount of support to keep the overhead down, is really typical with Chinese equipment.

Your best advice is going to be from people’s experience on here and then you’ll have to tailor that advice to your situation.

Razor weld couldn’t even design their own consumables, they had to make a direct copy of hypertherm, so what does that tell you?

You purchased yourself the most inexpensive plasma table with one of the most inexpensive plasma cutters on the market, the trade-off is user responsibility to read and understand their manuals and to reach out to sites like this. your alternative is to buy more expensive equipment which there is a lot of research and support attached to it but that also comes at a cost which you don’t pay for with the cheap equipment.

I do agree razor well does need to have a rewritten manual specific for their CNC model machine that could include a little bit more information. But I can also see why they’re hesitant because then people would look to those numbers as an expectation and the norm.

Ultimately I purchased a hypertherm 85.

Which keeps me up and running with almost zero down time.

Has cut charts that are very close to accurate with my setup besides the 300 IPM speed limit.

It uses half to a third as many consumables as a razor weld.

Automatically adjust air pressure based on amperage.

I also have full direct North American support.

But this did cost quite a bit of money like $5,000.+

Hypertherm is the Pinnacle of plasma torch technology no one else even comes close almost everything else out there is a copy of their tech over the last 50 years.

So you can see by the price range difference you’re thousand bucks is at the low end of the spectrum and with that comes the amount least amount of support and options and reliability and quality.

Razor weld is probably the best supported of the b and c grade plasma cutters.