Just wondering what size tip came with the plasma cutter?

If you have the X45 torch, the cutting tip is 1.0mm/45/50 amp, orifice hole is .040". And no there is no other cutting tip for that torch.

I appreciate the reply! - I looked everywhere in the “manual” that came with it. Much like the cut chart it’s not in there anywhere lol.

For 1mm the google spreadsheet only shows 4 thicknesses for 1.0mm tip

1/2 , 5/16 , 3/16 , 9/64 (for steel)

Can’t the machine cut smaller steel with this tip size?

sorry but im 100% new and frustrated from having to do more home work than necessary for a machine that cost 1000$

Sure you can, but do not expect to get good detail as the kerf is going to be at least .055" wide.

Everyone on this forum has been “100% new” at some time and all of them did the “home work necessary” to get their machine to work for them.

I’m aware - doesn’t make lack of manufacture support any less ridiculous though.

Ya get what you pay for. You want all the bells, whistles, and full 24/7 support go to someone who provides it. You want low cost, relatively easy to use if you’re willing to learn and do it yourself, and great support from the table mfr, you’ve come to the right place.

Have you tried to contact razor well directly their office is in Washington and their phone numbers on the back cover of your manual.

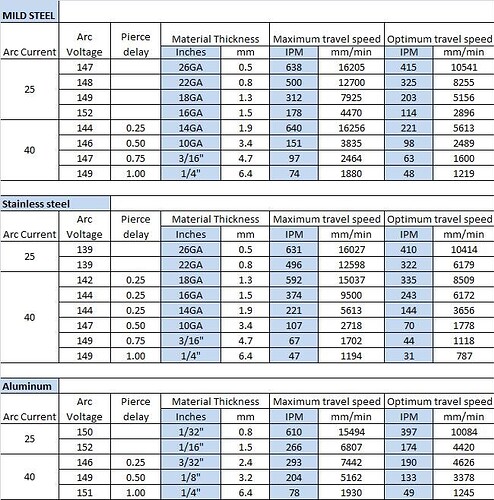

This is a cut chart that was provided directly from razor weld and has been posted to this website several times over the years.

Razor weld does get the job done but depending on what torch is mounted to it and what table it’s on and how your air pressure set up and considering they don’t grade any of the components by tolerances before they’re installed on their pcbs, there’s quite a bit of variance between machine and set.

All these cut charts are a good start but your particular situation will be slightly different.

Company’s offering plasma torches that have highly graded components and very tight tolerances can offer cut charts because one of their machines is going to act very similar to another.

Machines like the razor weld which are built on the premise as being as cost-effective as possible while providing the minimal amount of support to keep the overhead down, is really typical with Chinese equipment.

Your best advice is going to be from people’s experience on here and then you’ll have to tailor that advice to your situation.

Razor weld couldn’t even design their own consumables, they had to make a direct copy of hypertherm, so what does that tell you?

You purchased yourself the most inexpensive plasma table with one of the most inexpensive plasma cutters on the market, the trade-off is user responsibility to read and understand their manuals and to reach out to sites like this. your alternative is to buy more expensive equipment which there is a lot of research and support attached to it but that also comes at a cost which you don’t pay for with the cheap equipment.

I do agree razor well does need to have a rewritten manual specific for their CNC model machine that could include a little bit more information. But I can also see why they’re hesitant because then people would look to those numbers as an expectation and the norm.

Ultimately I purchased a hypertherm 85.

Which keeps me up and running with almost zero down time.

Has cut charts that are very close to accurate with my setup besides the 300 IPM speed limit.

It uses half to a third as many consumables as a razor weld.

Automatically adjust air pressure based on amperage.

I also have full direct North American support.

But this did cost quite a bit of money like $5,000.+

Hypertherm is the Pinnacle of plasma torch technology no one else even comes close almost everything else out there is a copy of their tech over the last 50 years.

So you can see by the price range difference you’re thousand bucks is at the low end of the spectrum and with that comes the amount least amount of support and options and reliability and quality.

Razor weld is probably the best supported of the b and c grade plasma cutters.

well put Sir…well put…

I bought my table full well knowing what I was in for as I read and researched the forums and Facebook and Youtube…

I knew it was a “starter” table…and the weakest link is the Plasma cutter…

it is like buying a buying a Mustang and putting in a 1L engine…looks good…does work…but performs like a Chevette…

Now…I did not buy a Hypertherm…I could not afford it…but I bought what I knew…an Everlast…it has it’s downfalls but I know what they were before buying it…

I did my research and knew it was going to work for what I wanted…for the time being.

as for the tip you have…I mostly cut with 1.0 and I cut anywhere from 1/4" down to 24gauge…I just adjust the amsp and speed…

yes I may have a wider kerf…and not have the fine details sometimes…but I plan for that in my design.

I appreciate the reply and your view.

Having no experience with anything here is overwhelming and it’s difficult to absorb every (sometimes different) thing you read when you don’t know which information is which when trying to your homework.

I bought the pro and have a refrigerated dryer, 3 stage regulator / filter / dryer and the motorguard toilet paper filter.

I guess if I had known it couldn’t take different consumables from the start I’d have gone with a pricer model.

I will consider it what it is and just upgrade to a better model and use this for slicing sheets off the tailgate when I get to the point where I need more detail.

Thanks so much for the reply and chart.

You’re very welcome.

Your razor weld will serve you well once you get it dialed in. use it to make some money, invest in something else later on.

It sounds like you’re well on your way for air quality it is absolutely pivotal when cutting with the plasma torch.

Crappy air quality leads to so many other issues.

THC errors

Low consumable life

Crappy cuts

By your description it seems like you’ve done yourself right.

It is definitely overwhelming and frustrating, you’re not going to absorb everything right away, it’s going to take time and you’re going to have to screw some stuff up first.

Everyone on here is more than willing to help other members.

This forum site is why I bought a langmuir and it’s the reason why lots of people buy a langmuir .

The experience shared here is invaluable. And everyone on here wants to see you and everyone else succeed.

The demonetization of information is what it’s all about.

Getting pretty good cuts on 14ga with 80ipm @ 30 amps so far. Will dabble more with higher speeds after I get more steel!

A question:

Does the Razorweld X45 Machine Torch on the Langmuir store work with this machine? It’s so confusing. If not is there an actual machine torch for it? Other markets for a machine torch?

thanks in advance!

Yes the X45 machine torch Langmuir sells will work on your Razorweld 45.

I see it’s out of stock - any other places to get that thing? Also does that also use only 1.0 consumables?

Thanks for speedy reply!