I would absolutely 100% go with the Hypertherm cutter if you can possibly afford it. More about that at the end.

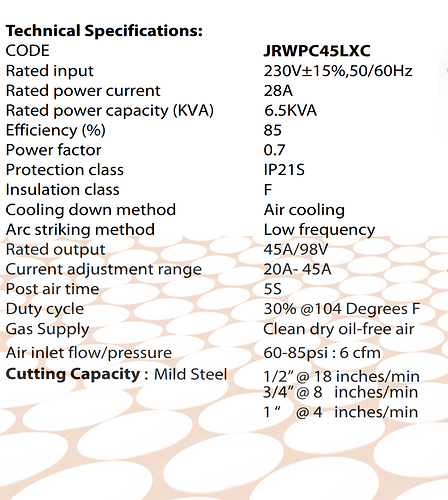

I can’t offer any personal insight on the Razorweld, but I have had two Primeweld Cut60’s, so I will offer a little bit there.

My first Primeweld Cut60 failed internally (un-resettable overcurrent light) within the first two days of use. Primeweld’s customer service is excellent; they had a new unit to me in about a week.

I’m convinced that the second unit “worked”, but I was chasing other issues for over a month, and when I went to wire the second Cut60 to raw voltage (STRONGLY recommended with the Langmuir table), I noticed that one of the resistors inside was burnt up, and it looked like it had gotten SO hot that it had partially melted the PC board that it was attached to. Once again, Primeweld was ready to send out another unit, but I asked for a refund instead.

Two units with issues, back to back…I admittedly have bad luck, BUT, I think Primeweld’s QC might not be the greatest, and honestly, their price reflects that. Their customer service more than makes up for the product short-comings, but with something that has as many variables as a CNC plasma application, I think people should buy the BEST machine they can afford, right out of the gate.

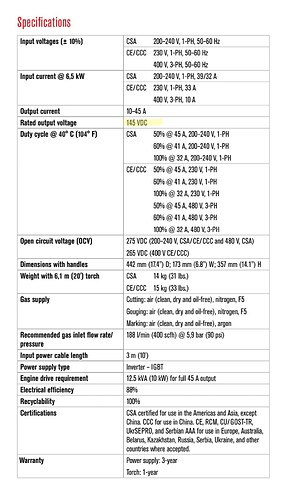

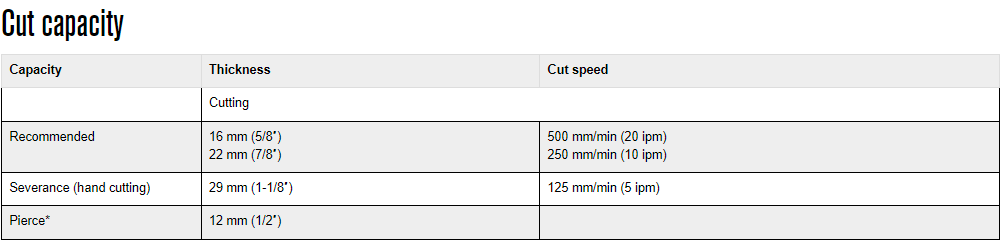

Now, it’s not to say that Hypertherm users don’t also have “issues”, but they seem a little less frequent. It seems like Hypertherm machines are very well made, and very well shielded. They also, arguably, have superior cut quality, a cut chart that will take 90% of the guesswork out of a beginner user’s learning curve, and up to 4 TIMES the consumable life, according to many users.

BTW, my Cut60’s were both NEW units, not the older ones that people historically had issues with. My last one was made in November 2022.