Also another relevant question for @cblanchard811 @chowpay @golferguy17 Are you running a PC or a Laptop?

@langmuir-daniel @langmuir-mike @golferguy17

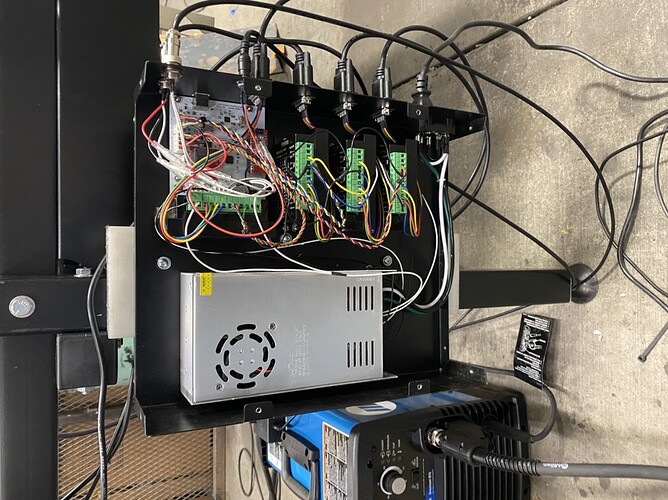

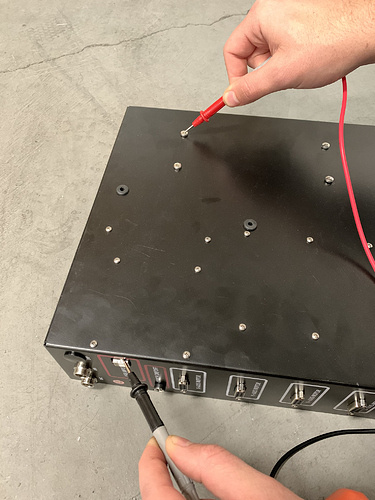

Ok update on what I have found and done so far there was continuity between the ac power supply and usb housing we have remedied that by making a stand off as pictured

Where we are having issues with continuity is from the usb housing to the work clamp via the THC cable

@langmuir-mike I’m running a laptop.

So I went out and checked for continuity between the USB housing and the Power Supply mounting screws and got some funny results… Essentially, I don’t believe the USB ground (housing) itself has continuity with the power supply, but the opening in the panel where the USB passes through does. In my case, the USB housing is biased towards one side of the opening and actually making contact with the case, which in turn causes continuity to the power supply. Hopefully the attached picture clears up what I’m saying. I also checked for continuity from the USB port and the slat bed, and couldn’t find any.

@langmuir-mike @langmuir-daniel There is some path way in the board from what we are seeing that has continuity to the usb housing…

If the THC plug is disconnected there is no longer continuity between the work clamp and usb housing

Also pulled the THC chip all is the same so it’s not that

@cblanchard811 I’m a little confused with the purpose of that standoff… Isn’t the case already isolated from the frame via the rubber grommets?

@golferguy17 that is the purpose of the grommets but in our case we had continuity between the usb housing and the ac power supply what we found was with the box off the machine it did not so maybe a screw cut thru the grommets and some sort of path was made it is kinda strange but with this stand off there is no more continuity… also try usb housing to work clamp see if you have continuity than if you do unplug the THC cable and check again

@cblanchard811 just checked usb cable to work clamp and have no continuity with or without the THC cable plugged in. Also, I can’t find any continuity anywhere between the electronics enclosure and the frame in any way. So it looks like my grommets are doing the trick whereas yours weren’t.

@cblanchard811 The THC cable should not be giving you continuity to the work clamp. Can you unplug the wires to your VIM box and check continuity between the Raw Plasma input terminals and the DC jack for PV Out. Check all the combinations for continuity, there should be none.

Are you checking for continuity with both the AC power cord plugged into the electronics box and also the USB cable to your computer plugged in and turned on?

@langmuir-mike originally I did not have the unit turned on and usb connected, but I now do and still have the same results.

I have continuity between ac power supply screws and the enclosure itself (specifically right where the USB port passes through the enclosure).

I found I am able to force the usb to disconnect from my computer and “chime” if I cause continuity between the ac power supply screws and the usb housing (found this out by accident as I was probing for continuity). I am able to do this repeatably so it’s definitely something to look into.

@golferguy17 Glad to hear you do not have the USB ground to work clamp issue. It looks like you are getting USB ground to AC ground from the power supply (through the enclosure) which would explain the skipping hole problem you’re seeing. Can you wedge something between the case and the USB plug like electrical tape to prevent contact from occurring here? This should fix the problems that you’re seeing.

@langmuir-mike I definitely can wedge something in there but I’m wondering if there is a better solution… it appears as though the standoffs behind the control board are not long enough to center the USB port in the opening on the enclosure (either that or the hole is in the wrong spot). Would it be ok to remove the control board and extend/add to the standoffs to push the USB port into the appropriate position as it passes through the enclosure?

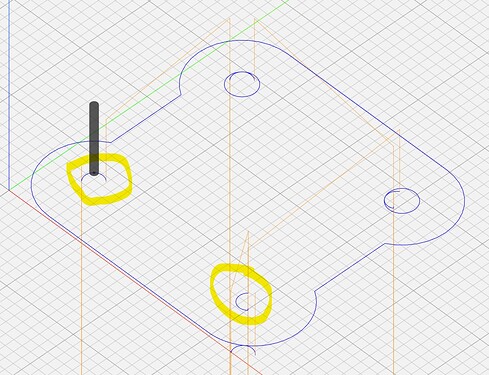

Loaded that tap file in https://ncviewer.com/ and it sure looks weird…2 of the holes look fine, the other 2 are not showing up right. It could be an issue with ncviewer itself, but I’d definitely double check the g-code or source (as well as all the other stuff y’all are doing to diagnose…) Disclaimer: not a g-code expert.

@langmuir-mike there is continuity between the red clamp port and pin 1 on the PV cable connector 222.0 K ohm and to pin 2 is 226.0 K ohm

Th black torch connector to pin 1 is 59.79 k ohm and to pin 2 is 55.89 K ohm

Does this answer your questions?

Is there another point you want me to test?

Or did I test it wrong altogether lol

Hi @cblanchard811 Ok your VIM is working properly. There is not continuity just high resistance through the circuit which is expected. Once you confirm that after everything is plugged in and powered and you aren’t getting the continuity in the situation below, your machine should work fine. Hope this helps!

@langmuir-mike once the THC cable is plugged in there is continuity between the work clamp and usb housing is this ok?

As far as continuity between the usb housing and power supply screws that was taken care of when we put that extra standoff between the machine and box our thinking was the screws maybe cut thru the grommets and some sort of path was generated cause with the box off the machine there was no continuity

Yes your isolation should work. What plasma cutter do you have and what type of live voltages are you seeing when cutting?

@langmuir-mike I went ahead and extended the standoffs on the back side of the control board. I extended them by 1/16" which seemed to do the trick. Not sure if it solves my no hole problem yet, but at least the USB port isn’t contacting the enclosure anymore.

Looks good! Let us know if this fixes your issue for good. Thanks again for helping us to better understand what’s going on so we can help others!

@langmuir-mike I am running a Miller spectrum 875

And as far as voltages I haven’t paid much attention to that I can put everything back together and run some test cuts and report back

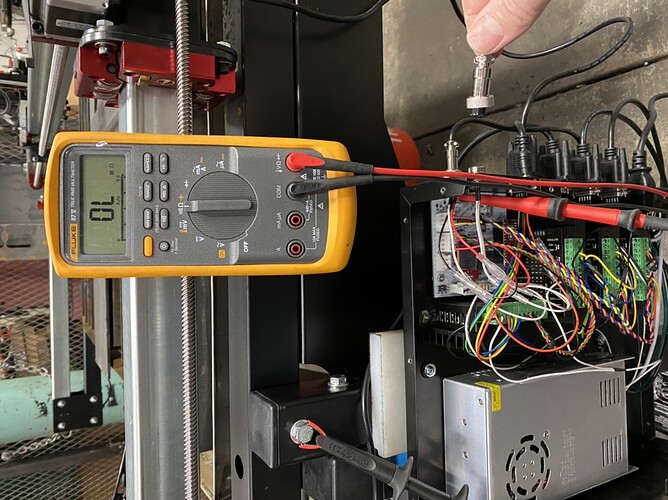

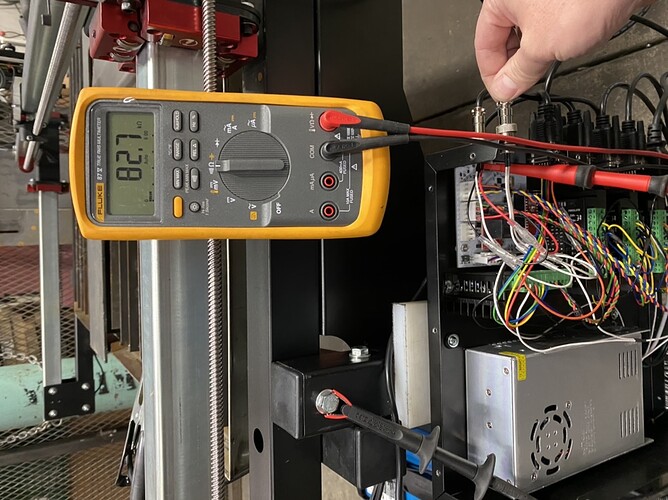

Here is what’s going on

THC cable unplugged usb housing to frame/ work clamp and with it plugged in I get this