I just got this machine and have no prior experience with plasma or CNC machines so I may need some in depth explanations.

We have been cutting out of aluminum for the last two days and the cuts will start out good quality and slowly get worse as we continue.

We are using air as our gas and 1/4” aluminum as the material. 40 amp plasma

Using sheet cam.

Here is an example of our cuts.

What are the specs on your air compressor and what plasma cutter are you using?

I believe the air compressor is 100 psi but it’s also hooked up to a saw in our shop. The plasma is a cut master 42

you need to know how many cfm it produces. You will find the plasma cutter has a requirement for a certain number of cfm at a given pressure.

I’ll look into this tomorrow thank you

Our compressor has

178 SCFM

120 PSI

5HP

Estimating 80 gallons

Well that isn’t the problem then… Watch the pressure gauge on the plasma cutter when the cut quality goes bad just to make sure you’re getting the right pressure at the machine.

Are you clamping directly to the work piece not the table slats?

I read SCFM is different than CFM, so not sure about that.

We don’t have a gauge on the plasma that I know of

We are clamped directly to the plate we are cutting

The plasma cutter sounds to my ear like the same noise it makes when it shuts off

what is the condition of your consumables??

Brand new, just changed them out before cutting

At the beginning of the last two days? or just before the cut pictured above?

Before the cut pictured above

is the THC rising during the failed part of the cut?

also installing a pressure gauge at the plasma to make sure your pressure is maintained at that end of the system.

what are you doing for moisture removal ?

Ill check on the THC and get back to you, right now we just have a filter on the back of the plasma

there is a good chance water vapour is causing issues.

you currently set up is not good enough

this could wreak a new set of consumables imminently

2 Likes

This is the filter we are currently using… what would you recommend. When I take the air hose off there is water vapor there

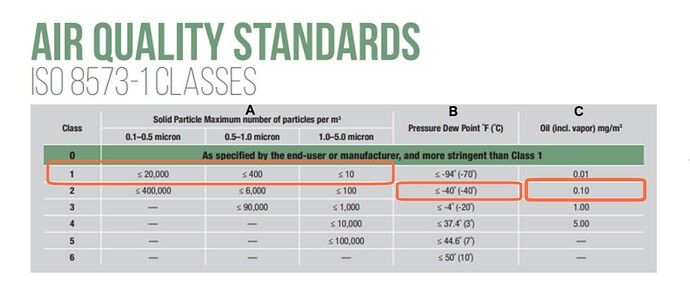

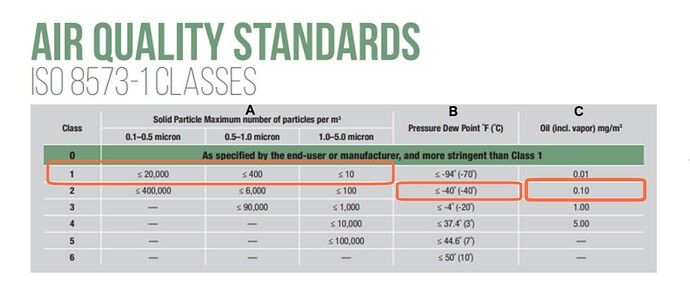

Start with a passive or active ambient cooler.

Then a refrigerated air dryer

Then a desiccant cell

then a rock catcher like in your picture above.

this is the standard you should be aiming for

2 Likes

And @Elijahpekaar Welcome to the Forum !

1 Like