Slowly getting my TD Cutmaster 82 with hand torch dialed in. Pretty happy with surface finish and dross but I’m fighting a really nasty bevel on anything .125" and thicker. My question for fellow Cutmaster owners is there a setuo you can share that works well for you? Say anything from 1/8" to 1/4" mild steel. Trying to get a baseline setup that I can tweak from there.

Thanks

Also have checked the usual suspects. Have dry air, new consumables and the torch trammed in. Believe my problem just lies in my inexperience with plasma setups.

Air pressure at torch and cut height will have effects on bevel as well.

How does air pressure affect bevel? Is there a relationship like lower air pressure results in bevel or the. other way around? These are the kind of tips that are really handy!

This is pretty helpful too

I’m fighting the same thing with same machine. Have you come up with anything?

It’s been frustrating to say the least. Put the torch on the track burner and perfect cuts, use the exact same settings on the CFP and get terrible results. The single biggest improvement I’ve made is to disable THC. The THC has proved itself to be complete garbage and utterly unreliable. With it off I’m getting pretty good results.

2 settings that work well for me are

1/8" CRS 45amps 60ipm .16" standoff .9 sec pierce delay.

1/4" CRS 60amps 50ipm .16" standoff .9 sec pierce delay.

The pierce delay seems really long but anything much shorter and it tries to move before the torch has fired on my machine. I also keep the springback set at .0"

I don’t trust CFP enough yet to run parts of any importance but misc tabs, brackets, gussets had good results with those 2 setups.

Hope that helps some.

1 Like

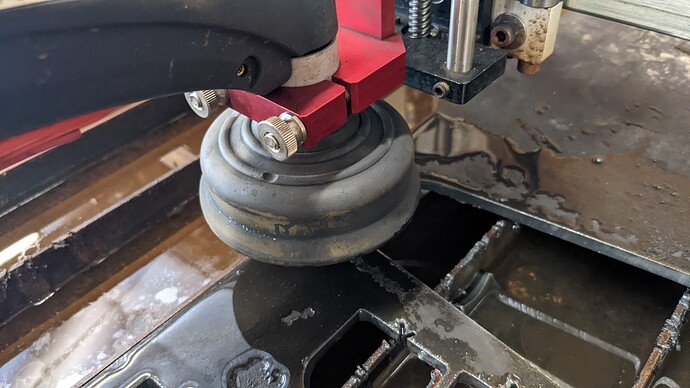

Thought of another thing. The CM82 torch is really too big for the LS holder. Found the torch would shift out of square in the holder. Didn’t want to risk damaging the torch by over tightening the clamp. So bored the clamp true to size. While I was at it, studded and added thumb nuts. Makes for easy tool-less parts changes and excellent repeatability.

3 Likes