Does everyone, hand enter a new tool for each cut, dependent on material? I had a razorweld 45, and would just change the cut speed, for the thickness and material. Any help would be appreciated. Also if someone share the settings for hypertherm xp45 for fusion that help me get going in the right direction.

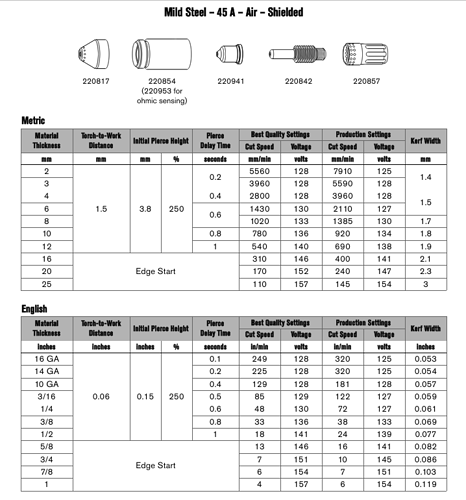

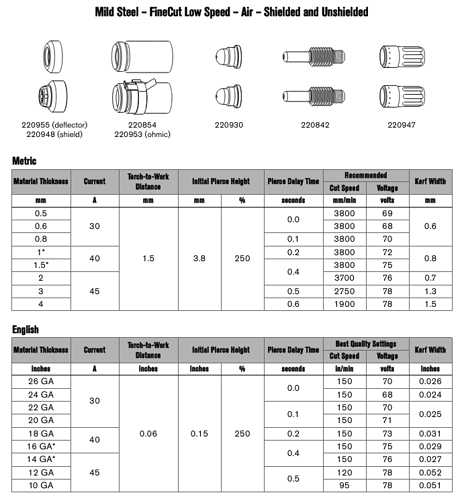

For mild steel and normal cut consumables (not fine-cut), this is the chart in the book.

As far as entering information for “tools” in Fusion 360 (not familiar with SheetCAM) the only information that flows from the tool profile to the g-code is the cut speed and kerf width. Amps is set at the plasma machine, the plasma machine determines the air pressure. The thickness of the metal is never really entered.

Some people enter the voltage and air pressure just for reference and sometimes people set the voltage in FireControl if you are not using THC/smart voltage.

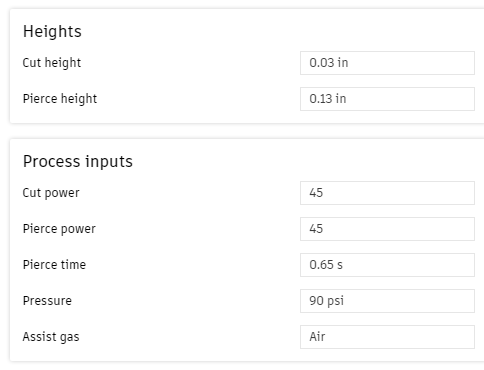

Other issues like the pierce delay, cut height and pierce height are entered just before Fusion 360 converts your contours to the gcode, during post processing.

This is all of the tool data that is not currently being used by Fusion 360:

So, in a short answer, everyone (most) have entered some detail for each type and thickness of metal in their tool set profiles. How much information you put is up to you but basically, Fusion 360 is only using the cut speed and kerf width from the tool and then your post processor information is entered just before the g-code is assembled.

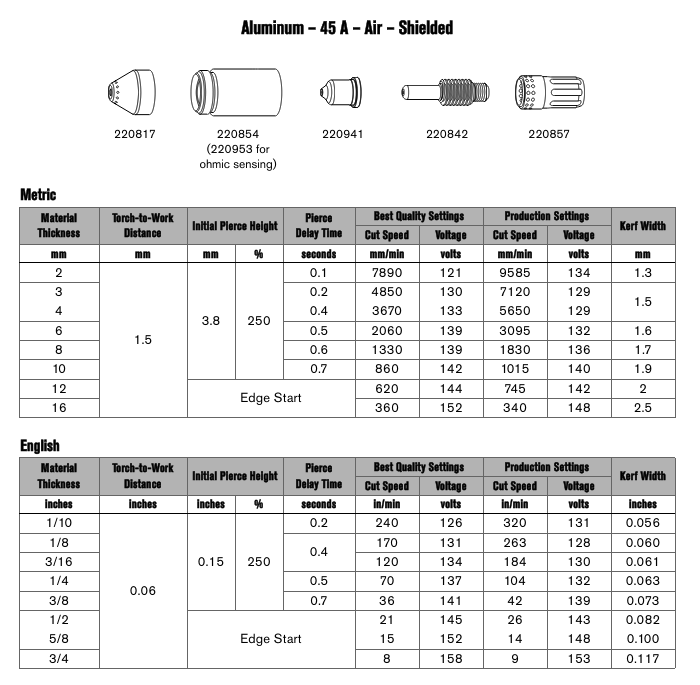

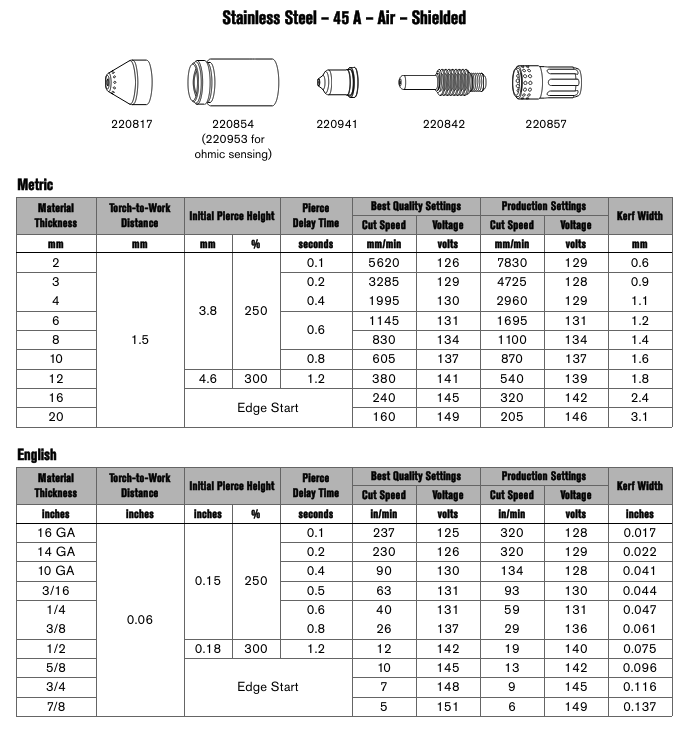

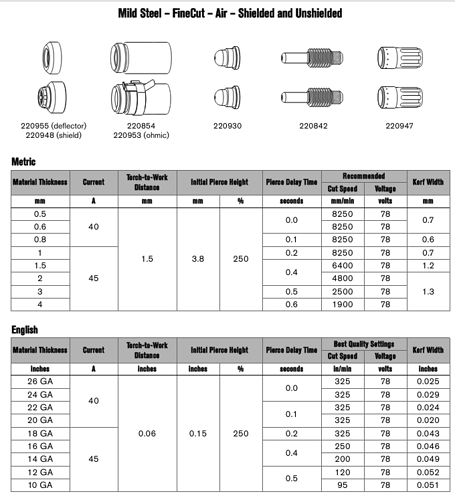

Here are some other reference charts:

Make sure that when you enter the chart into fusion or SheetCam that you add .3 seconds to every pierce time due to the way it is calculated by Hypertherm vs Langmuir.

Like @ChelanJim said, Fusion will not pass the Cut / Pierce height or Pierce Delay to the G-code, but I find that by having them entered, I can quickly verify the correct values when selecting the tool. (Fusion will display them in the scroll list at the lower right.) This provides me a reference other than going back to the cut sheets. Additionally, if I’ve found that I need to “tweek” the settings, I can record them with each tool / thickness.

Thank you, for the information. It helps to have a easy place to ask questions.

I see you have several answers already but I made this video for another topic on the forum about this same subject. it may be helpful for someone in the future.