It looks like it’s trying to push down the entire time to lower the cut height . Is something mechanically preventing it from pushing down the Z access?

No, not at all. Torch moves up and down just fine while jogging it up and down. Moves just fine during the pre cutting moves as well. Will jog down below the work surface with no problems.

Could this be the grounding issue I’ve read about? I tested the resistance from the outer part of the USB plug to the slat bed with the usb plug plugged in and work clamp attached to the slats. I get 4K ohms in this configuration. I removed the USB plug from the fire control box and disconnected the grounding clamp from the slats. I get about 1.8K ohms in this configuration.

Further testing… I measured the voltage coming out of the divider from the plasma and get 3.5 volts. I then measured the voltage coming out of the VIM module and get 2.4 volts. The 2.4 volts would seem to be correct based on the THC troubleshooting guide.

I’m bothered by these readings. The troubleshooting guide seems to indicate that these readings should be greater than 10K. I did check that the control box enclosure is isolated from the frame of the machine electrically. If I measure the resistance from the control box (on a bare metal section in a drilled out screw hole) to the frame of the machine I show an open circuit.

What’s also bothering me here is during the straight line cut test I’m measuring 3.5 volts which undivided would be 175 volts. However during the THC test it’s reporting 56 volts.

Can you supply the gcode? Or perhaps tell us during the course of the file, how many times did that torch actually touch down to the metal?

The reason I ask is because the IHS light came on 7 times during that operation.

I am now re-reading that you were just cutting a straight line. You likely have a break in the wiring for the IHS line or the contacts are loose. Check and see if that wiring is loose. Every time the light comes on, FireControl is telling the torch to lift up 0.06 inches. Since your voltage is reading too high, the THC is telling the torch to lower. They are fighting each other.

If it turns out the wire(s) is/are loose, here is the Langmuir guidance to disassemble and reassemble.

IHS Contact Switch Components Swap Guide.pdf (7.1 MB)

It sounds like the voltage going into the electronics enclosure is correct, so that leads me to think the THC module may be the issue. I would open the enclosure and pull the THC module and re seat it.

That screen recording was not a straight line cut. That was a rectangle. My voltage tests I describe later in the thread were done using a straight line cut.

The code for the test where the screen recorded is below…

(v1.6-af)

(LS Forum community post)

G90 G94

G17

G20

H0

(Torch Setup)

( MS-10GA-135-STD-45A-128V )

( 45A )

(2D Profile1)

G0 X0.8504 Y0.125

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0. (IHS Springback + Backlash)

G92 Z0.

G0 Z0.15 (Pierce Height)

M3

G4 P0.5

G0 Z0.06 (Cut Height)

H1

G1 X0.6535 F129.

G3 X0.5285 Y0. I0. J-0.125 F64.5

G2 X0.5 Y-0.0285 I-0.0285 J0.

G1 X0. F129.

G2 X-0.0285 Y0. I0. J0.0285 F64.5

G1 Y8. F129.

G2 X0. Y8.0285 I0.0285 J0. F64.5

G1 X0.5 F129.

G2 X0.5285 Y8. I0. J-0.0285 F64.5

G1 Y0. F129.

G3 X0.6535 Y-0.125 I0.125 J0. F64.5

G1 X0.8504 F129.

H0

M5

G0 Z1.

M5

M30

(PS129)

Yes. Turns out it would be the same thing as it was only cutting one contour. The gcode for the rectangle only required touching down once to establish where z=0 was. That is the one time that IHS light should have come on. All of the other times it came on were because the IHS circuit was erroneously telling FireControl that the torch was hitting the plate.

Jim is on to something with the IHS light coming on. That indicates that there is a problem wih the IHS wiring or the IHS switch is getting hung up on the lead screw and opening every time the THC tries to push the torch down, which tells Firecontrol to raise the torch again.

OK, I checked the brass contacts for the IHS switch. Nothing binding, no visible issues. I used some light grit sandpaper to clean the contacts. The IHS is no longer triggering during the run of the part. But the original issue with the voltage remains.

is the usb shell on the control box touching the outer shell of the control box?

can you record the actual torch cutting?

have you checked your cut height?

can you grab a picture of how the torch is mounted?

the answer to these might be a lightbulb moment for someone.

In this photo, the USB shield is touching the housing, which is a major issue.

It creates a ground loop that seriously affects the THC control. We have seen many instances of this issue driving people up the wall

it is touching you need to shim out the board. may not be all your problem but it doesn’t help

Try sticking a piece of paper between the USB and the metal enclosure and see if that changes anything.

I loosened the screws and inserted a piece of paper around the outside of the USB connector. Before it was showing a short from the outer jacket of the USB plug to the enclosure. Now I’m seeing 1.5K ohms between the outer jacket of the USB plug and the enclosure. Ran another test cut. No change.

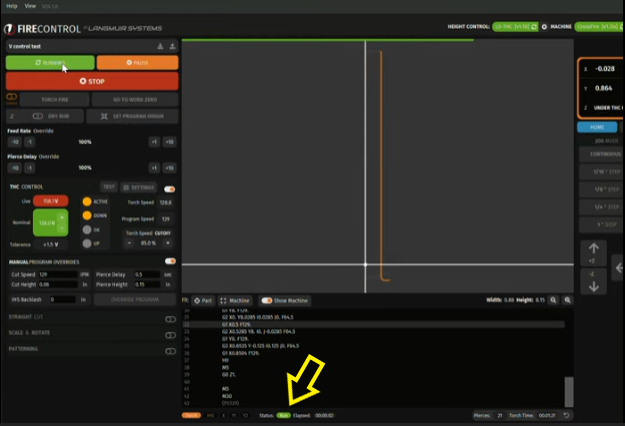

The THC test shows 56 volts. The voltage measured going into the VIM box from the plasma is 3.5 and coming out of the VIM it’s 2.4 volts. This equates to about 175 volts of undivided voltage. Should be THC test be showing 175 volts as opposed to the 56 it’s showing in the THC test? Running a cut I’m getting the same results from the screen recording I posted earlier.