I have crossfire Pro with fire control and

sheet cam

I have tried the Settings and sheet cam

That easy scriber suggests but I cannot get it to work right

Does anybody have any suggestions

thank you

What settings have you tried?

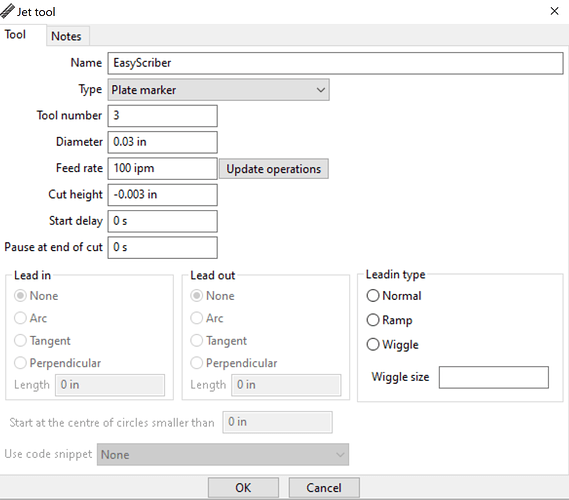

Here is what I do:

Use the standard FireControl Sheetcam post version 1.5

In tool setup:

Set pierce height to 0.001

Set cut height to either 0.001 or -0.001. Y

Set pierce delay to 0.

Set plunge rate to 50 ipm

Don’t use lead in or lead outs.

A non zero cut and pierce height are required. This way the normal IHS is done.

Generate the gcode.

In Firecontrol turn OFF THC. Turn off your plasma, put in Easyscriber. Run.

If that doesn’t work provide more details then “it doesn’t work”.

Thanks I will try that

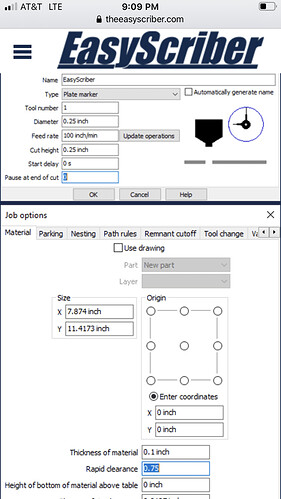

This is the setting I tried tried

And I set up to plate marker

And I know I cannot enter a negative z value

And if you put zero in The Pierce height Pierce Heights and cut height that turns off the IHS is that correct

Don’t set it up as a Plate Marker, set up as regular plasma tool.

I will do that

Thanks again

I got it working is there a way to get more preload

The cuts gust do seem deep enough

You can try increasing cut height in the negative direction. Be careful though. I’ve gone as far as -0.005", which isn’t much really, but didn’t notice much difference.

Things to keep in mind:

- it doesn’t raise the material, it’s a shallow scribe

- if you paint over the scribe markings, you will most likely not make them out.

- use cross hatching in your designs

- if you are using it to layout drill hole locations etc, a quick hit with some spray paint will make the markings stand out more. Or do like every youtuber and get that blue layout die

- if you want it to stand out and the end product is to be painted, it’s probably best to do the scribing after it has been painted, then if mild steel clear over it. Depending on what you are doing that may not be too easy to do as: one you need to be able to accurately position the scribe, two you need a way to hold the material in place.

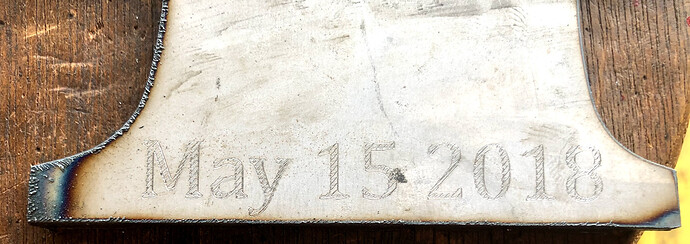

This is on hot rolled that has had the mill scale removed. The cross hatching is what makes it legible from a distance.

I am doing a liup to a electrical control box buttons and switches trying to do the labeling .090 aluminum

Trying to upload the picture he keeps telling me it’s too big

But I really do appreciate your help

I actually got it to work I just don’t think it’s the right tool for what I’m trying to do

Here’s something similar, but note it is painted aluminum.

Neat!

It looks, from the video, that the scriber is spring loaded so that deflections into -Z will simply increase the scribing pressure. If that’s the case, it seems as if your -0.005 inch deflection was very conservative. Am I missing something?

This video is pretty impressive, however, Easyscriber’s website claim that there is no ‘additional’ SW required seems a bit, shall we say, ‘optimistic’?

Yes it is spring loaded. But the Z axis is floating, so it may not make a difference driving negative z until the float distance is taken up. Also according to this video they say that pressure doesn’t need to be high

Right, that blasted floating Z axis! It will get you every time (you need to do something the machine wasn’t designed for…).

Thanks for the explanation! On to the next problem…

I got my easy scriber last night and modified it to fit my razorcut torch. I had issues getting it to preload into the metal. I ended up putting a small bungee cord around the z axis assembly so it would take a little more force to open the IHS contact. This let the easyscriber preload and work perfect! Check out the video. Hope it helps.

Did you try a negative cut height (0.001 to 0.003) before trying the bungee cord?

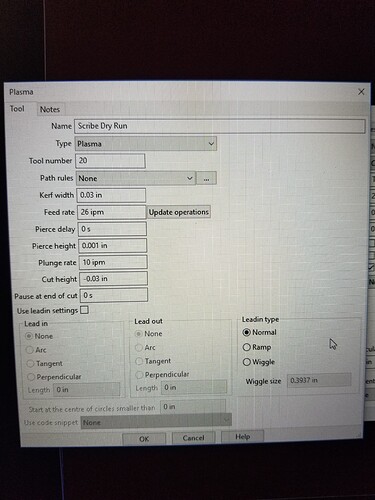

I tried to put in a negative cut height in sheet cam. But when entered it would revert to 0 cut height. And then the Initial Height Sensor wouldn’t do its thing and it would run the loop at whatever height the torch started at, regardless of my Z zero in Fire Control.

Did you select the platemarker as the type of tool?

Just tried this with the 1.6 post in Sheetcam and got a negative cut height.

G1 Z-0.003 F100.0 (Cut Height)

Anyway if what you have works, not too important.

Ooh. Good call. I initally did plate marker. But when it wouldnt tuch off i changed it to a cutting tool. I should go back and try again!

HELP!

I have the Easyscribe but honestly havent used it much. I want to mark cross hairs for drill holes. I have it marking well and retracting between “cuts” but my problem is it is retracting too far in Z. I use sheet cam and generally love it but I’m basically crashing my torch in the positive Z between each move with this scribe. I do have THC turned off.

I have the scribe set up as below, and I changed my rapid clearance in job options to .25" from 1" and its clearly not recognizing the change. Any suggestions to fix this?