i would recommend wiring it up to RAW voltage. a few of the newer "older " versions were having issues with the divided voltage from the cnc port and were putting out too much voltage and sometimes frying the DIV side in the Langmuir VIM box. It’s a simple process to wire it RAW and the hardest part is removing all the screws to take the cover off. you can still use the cnc port for torch on/off.

On the new updated one I’m testing?

Does it not have a serial number on the new one that you are testing?

Sorry, I’m brand new here and don’t know all the tweaks about messages. I am grateful you made the subtleties more clear.

Yes it does… just making sure you were actually talking to me… lol

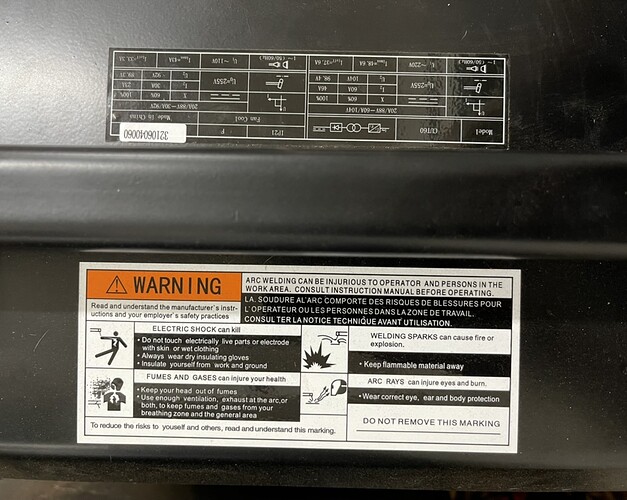

No serial # on the back, it’s on top now next to the warning sticker.

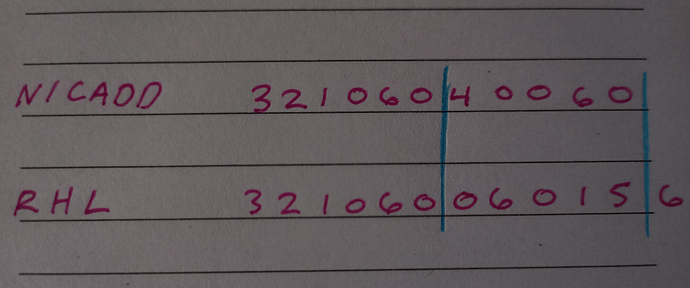

A couple interesting things when you compare these two numbers.

One has 11 digits the other 12.

The first six digits are the same.

It’ll be interesting to compare a few more.

I’d guess the first six are a company code and they are adding an extra digit so they are ready when they sell more than 99999 of them.

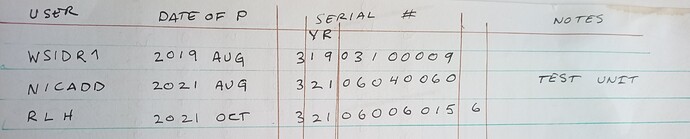

My serial number is 31903100009. I bought it Aug 2019.

Looks like maybe digits 2 and 3 are the yr.

if the problem is actually solved, wonder if it will be on the compatibility list…time will tell, and if it works, its a whole new ball game…by itself, its a great cutter…cnc compatibility…huge

you can still use it connecting it to raw voltage.

Thanks for the number @Wsidr1, I also agree that digit 2 in 3 or likely year code

Only 3 codes and a lot clearer picture.

Now is the fourth fifth digit month and six seven day?

Another thing in common is that the 4th and 9th digit have always remained zero.

I posted this elsewhere so I will inject it here also.

I have a Crossfire and Prime Cut 60 that has not been up dated. I had the issue of excessive voltage on the Div port also.

The way I solved the issue is to wire the CNC Plug to supply the Raw Voltage protected by 100K resisters. This allowed the use of the raw voltage inputs on the VIM box… The resting voltage I have is .3 volts, The test voltage is 70+ volts and on 18 Gage sheet metal it is 54-56 volts.

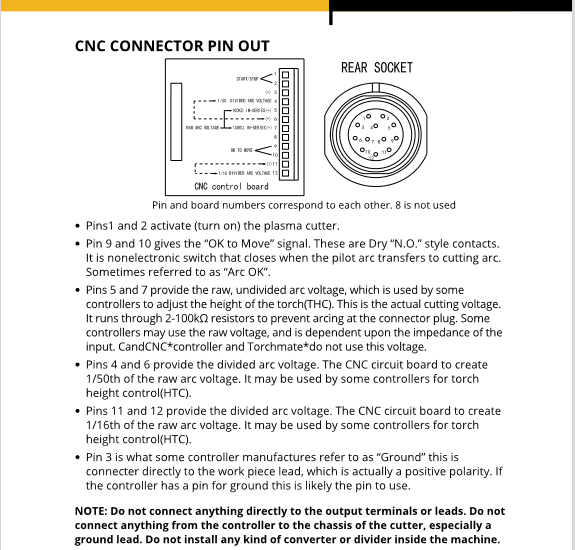

The issue that took me the most time was figuring out that on the thin stuff I needed a test cut to get the target voltage because the Smart voltage won’t work . Once that was done the THC operates well. Here is the Connector Pin out so you can find the raw voltage Pins 5 and 7. Remember 5 is the plus voltage and 7 is the negative, this is important.

Hope this helps

Thanks a bunch… As I said ealier, I am new to both the Prime and Langmuir protocols. It’s not quite plug and play, and I appreciate the wealth of experience that is out here.

New here i ordered my machine a couple days ago. Thinking of the Primecut60. Will wait for the new model to come out and see if langmuir adds it back to their compatability list. Has anyone tried adding EMI wrap to thier cables to cut down on interference? EMI/RFI shielding for cables, filters & connector gaskets

It’s all been done, many posts on here about it.

As for me, I have my control box electrically isolated from the table ground, the computer is a PC and it’s ground pin has been removed as well as the monitor, 15ft USB cable with double ferrite beads at both ends, and there are NO, repeat NO ferrite beads on the raw-voltage sample line going to the THC voltage divider (IT REALLY HATES THAT). My CUT60 plays perfectly well with the table, no issues.

all that needs to be done to minimize interference is move the cutter farther from the control box. the cables that langmuir provides aren’t long enough to allow this so i would suggest purchasing 2 extension cables. one for the torch on/off and the other for the THC and place the cutter on the outside of the table opposite the control box.

also, if you are going to use a longer USB cable, purchase a known branded one. the cheap amazon ones don’t work well. When i first had the original crossfire, i used a cheap amazon 10’ usb cable, added a ferrite choke on the end and it worked great. Upgraded to the PRO and that same cable wouldn’t work for anything. as soon as the torch fired, firecontrol would freeze with torch on. i then bough a premium Belkin 10’ usb printer cable and it’s been working great. Also add a ferrite choke to the end.

bunch of previous posts on this in the past

yeah probably from me, so what’s your point?

maybe look before you leap…i can expand if you dont understand