Thank you for the information

RAW voltage is the path for your machine ![]()

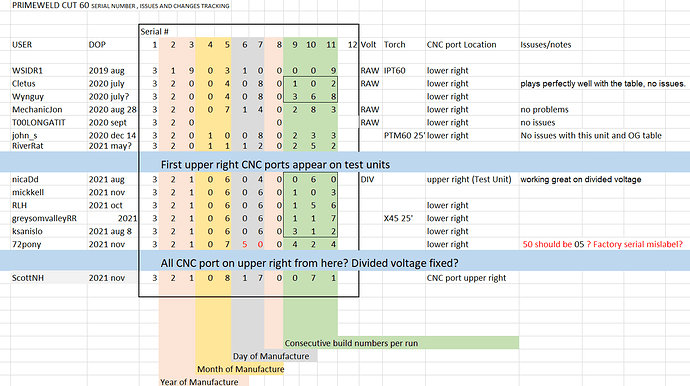

also looks like your machine was produced on the same run as @Cletus

I am going to label that in red. It has to be a mistake at the factory. I am sure its July 5… Hopefully we get some more serial numbers near your sto help solve this puzzle.