Thanks for the quick response, I’ll order them.

I used a Everlast 60s for quite some time. It’s definitely a good machine for the money.

Something similar to what you have only with a pitched roof, it will be in the center of the garage. I am interested in how you are going to vent, I am thinking about insulation in roof and some type of cooling fan with vents near the floor and the fan will pull up through and past the compressor head and out.

ttoy360,

My current plan is leave the eaves between the rafters open with hardware cloth, or maybe fill in with some perforated soffit panels.

We are out in the sticks so I am not super concerned with noise level outside the shop/shed. I might put rigid foam panels in walls and ceiling to reduce it, knowing full well that having open vents will still leave openings for sound to escape. But I have a stack of leftover foam sheets, so why not…

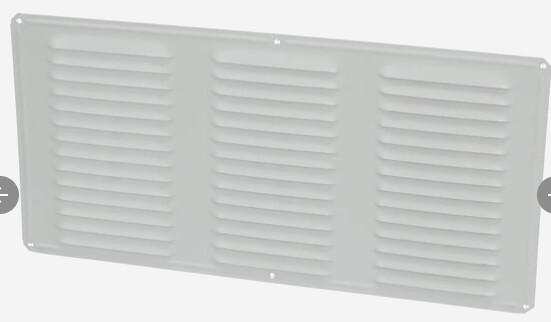

I plan on using some cheapo soffit vent convers with screen that I have laying around, down at bottom of wall.

I guess I will find out how adequate that is, and if necessary add an exhaust fan into the mix. I admit to not having thought too much into this yet (ventilation).

Thanks for the info and it looks like you have given it some thought to me, also at least you are getting it done…Great Job

@ttoy360, I decided to use the stack of 1.5" rigid foam insulation I had laying around. It can’t hurt. Mostly because one side gets direct sun in summer, and maybe it will absorb a little sound.

Will do ceiling too this weekend.

Same problem here, part of my order arrived and I got to unbox the water table and legs but the guts didn’t show up until we had left for vacation of course! So it’s there waiting for me!

to this in only 2 days. wont let me put video.but it WORKS!!! sooooo happy.

by the 3rd time trying to run it no issues. GREAT MACHINE!!!

Excellent !!! Well done sir … This should give a pretty fast ROI …

Nice job let me know how your air dryer system works pls.

Nice! Was wondering what your order date was? Ordered mine about a month ago and wanted to get a feel for how close the lead time estimates are currently. I’m sure I have at least another month to go as they were quoting 5-8 weeks when I ordered

i ordered 2/23. all boxes delivered by end of week 5/5

i dont have one yet. just using an inline water separator right now.

Nice setup You will like having the compressor outside the main shop. The big ones aren’t too noisy yet for some reason they bug me when they turn on .

One thing I don’t understand is why do folks build the dryer out of so many feet of copper and not run it around the shop for other uses? That way you have a dryer and a distributed air system .

Cools the hot air and collects water droplets forced out of the hot air at the bottom of the runs as it cools down.

my understanding is the numerous vertical drops are one of the keys to how it works. and it is not that many feet - about 40ft in my case.

Also, I think it is preferable to have it in between the compressor and the tank, as opposed to down the line, reducing moisture in tank and storing cooler air.

I am just learning (trying to) about all of this (compressed air, dry air) stuff.

Someone smarter and more knowledgeable on the subject might chime in.

Cools as it runs around the shop too and I mounted it higher on the wall and when I bring down a drop I put a ball valve below the drop just like those pictured loops. The plasma cutter is on the end of the run.

bbaley, though I get that, I don’t care that much about water in the tank as it is unavoidable to some degree. What I want to avoid as much as possible is the water to the tools.

I get very little water out of my drops and none at the end of the line. So minimal going to the tools.

But whatever works for you…just enjoy the process.