Interesting, I wonder if a Flocking tool would work then…

Never seen one of those. If you just put powder in it and shake it I would say no unless your part is flat and your just applying to top

The part is flat. Yes, the powder goes in the tube and you hand pump it. The turbulence fluffs the powder out the narrow end in a cloud.

I have one and I have some powder coat thanks to @Phillipw I’ll give it a try.

Try and do a video or pics of the whole process if you can, I am curious of what you end up with.

Hmmm you already got your powder from @Phillipw ? Must be my 50lbs got held up in customs,…being white I can see that happening. ![]()

Ok,

#1, a Mini Flocker is NOT the right way to evenly distribute Powder Coat! DAMHIKT!

#2, this won’t work for my task as the fused Powder won’t reliably stick to the painted surface.

I found I could evenly distribute powder by lightly tapping a paint filter with just a bit of powder in it and dusting the surface of the plate. This process MIGHT work if you have bare metal that’s roughed up for bonding, but I didn’t test that since it didn’t fit my application. Maybe I will at some point, but it’s not on the horizon.

So did you pursue this any further? or did you go a different route?

I would really like to see what you were trying to achieve

No, it wouldn’t bond to the base paint so I’m pursuing another approach for my task. I suspect that the Laser exposed Powder coat will bond to bare metal (if prepped properly) if it’s a thin gauge (smaller than 11ga) . There is probably a narrow window between underheating (and getting no bond) and overheating and the powder coat burning.

If and when you pursue this I would love to see your results

Do you guys know of ways to increase compressor cfm without getting a new compressor? I bought a ir 80 gallon compressor I think it has 15 or so cfm and at the time I thought it would be more than enough. But now as ive started sandblasting, it’s less than adequate. Really hoping I can get some more flow from this compressor.

what size air lines are you using and what psi are you running? i switched blasting media and was able to drop the psi to my compressor with decent results and my compressor runs a lot less.

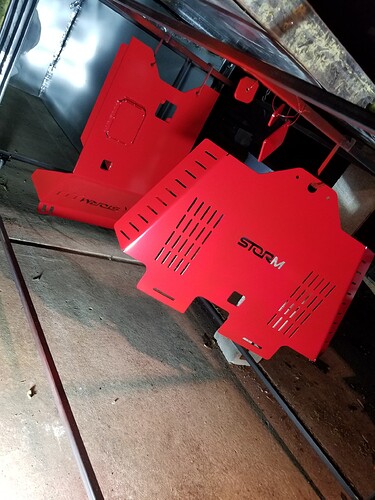

Powder coating has turned into one of my favorite things! Been so much fun learning and seeing the transformation happen! A massive upgrade for my little fab shop! Done alot of skid plates with some rock sliders, dirt bikes stands…etc mixed in!

and the Media is…

I run 3/8 air lines with the 1/4 high flow fittings from milton. I use green diamond media 40/70 at 50 psi

By eliminating as much resistance as possible .

By running your system at the lowest pressure possible while still maintaining operating pressure at the tool.

Low static pressure is the key

At one point in time I used glass beads mixed with coal slag media I had to run around 100 psi to keep good media flow. Switched to glass beads and soda I was able to drop air way down and it works pretty good. You just have to make sure your dust collector works good and washing parts prior to paint and powder is a must.

I was at Fabtech a few years ago and talked with a guy about this stuff. I never did try it but he said it worked great. told me it would clean like crazy but would not frost your blast cabinet window. I dont see how that could be.

Document_2023-05-31_200222.pdf (1.7 MB)

It seems to do a amazing job I will have to run it a while to see how it does on the glass.

That is interesting.

Right now, im just using the dust deputy on a shop vac. I still get a fair amount of dust in my cabinet. I need a more efficient dust collector. What are you guys using? Im looking at the one from Eastwood. I’m going to switch out all my sandblast lines to 1/2

All I use is a large shop vac with a vacuum bag inside to help keep the filter from stopping up. Seems to work pretty good. It is easy to tell when it isn’t pulling good. When right my gloves will be pulled out straight.