Thank you all for your reply I will look into the different programs and get learning so when I receive the machine I will be able to start cutting. This is a good community thank you all.

Start out simple. Don’t get caught up in upgrades right off the bat. Get your table working. Get started learning your software now… Have a couple of projects in the hopper. There will be a few minor bugs, but nothing that should take more than a day to troubleshoot. If I can get mine working good (and it is) so can you. This is an entry level machine and once you get going your going to be getting better than entry level results. Manage your expectations this isn’t going to pump out ultra precise parts… they’ll be pretty dang good but not perfect. Once you’ve got some projects under your belt your going to find out that just like any other tool it’s the operator that makes all the difference. You’ll under stand now to get around the weaknesses of your table and you’ll be able to make it “sing” any song you want. Try to remember that this is just a tool that speeds up how awesome you are… it doesn’t make you more awesome.

I love mine… I love that it’s not one of those monstrosities you see in big shops. I’m a weekend warrior I don’t need to blow the pants off the competition I just need to do my thing and this thing really helps with that. I can make some pretty good cash with small projects, but a lot of the time I’m doing things for myself or family too. It’s great for that.

Try not to wish you’d find the perfect love, love the one your with. Same goes with tools.

I felt the same way about 3D printing at first too, and that was MUCH smaller investment (I had a $600 budget). I spent weeks and months going back and forth between what style of machine, and what brand… then every time I thought I settled, I’d see someone post a horror story about their experience.

Another problem I had, that LUCKILY isn’t a problem with CNC plasma tables (yet) was, every time I thought I had my new 3D printer “picked”, I’d read a thread online announcing a BRAND NEW model, that promised to be an “(insert my chosen printer) killer”

But when I would wait for the new model, I’d read that the new model was a “disaster”, people would quickly point out all the bugs and flaws in it’s design, and this would make me happy I didn’t become an early adopter, but it also shook my confidence even more.

So the I was leaning towards one of the more “tried and true” defacto standard models that has been available for long time, and was widely used.

I thought I was settled on the Creality Ended 3, but once again… as I was about to buy, I had realized they had released the Ender 5 a short while earlier, and that it was basically an ender 3, except with upgraded hardware/electronics, and a more “sturdy” cube style frame. So I bit the bullet and bought one!

Within the first couple of days of using it, I realized that I HAD made a mistake… and the mistake was WAITING to buy one as long as I had!

I quickly realized that if I had bought any of the prior models I had decided on a YEAR ago, that I would likely be perfectly fine with it, but the moral is, I would have had a 3D printer a year sooner! So by getting “cold feet” like you are right now, I ended up losing out on a year or quality time with my new toy!

By the way, I’m in the same boat as you are, ive never owned a CNC plasma, I made the leap and bought the Crossfire Pro based on a friends advise who had spent a reasonable amount of time researching them… so I spent maybe 15 min researching myself, and I decided I was going to pull the pin and pre-order a XFirePro the moment that it went on sale!

I had a little remorse a couple times while I was waiting for the pre-order to ship, but I just remembered my 3D printer experience and reassured myself that I’m better off tinkering with a brand new model (even if I have to iron out a few bugs first) than I would be with NO plasma table, because I was playing the waiting game.

It would be different if Langmuir was a new company and the Crossfire Pro was some Kickstarter pipedream, but Langmuir is way beyond that point by now. They’ve learned enough with their first product in order to design a new model and deliver it to customers without the risk of it being a total disaster.

I think we’ll be fine! I can’t wait to share with each other, all the cool projects we’re cranking out with our new Crossfire Pro tables in a few months.

Talk to you soon new friend!

I started replying to this thread a couple times and discarded it. I’ve had a lot of frustration with the whole Crossfire experience but even more success with it, so it’s hard to sit here and list all the negatives and bash the experience when the price point of the Crossfire got me into the CNC game.

I’ll tell you my expectations and intentions when purchasing: I had a 45amp plasma with handtorch and was shopping bumpers for my Jeep Grand Cherokee. 2 steel bumpers were going to cost almost $2,000. My idea was to buy the crossfire, use my plasma and 30gal air compressor, and essentially break even vs buying full bumpers, all while gaining a new tool for the shop.

Misconceptions and costly fixes:

My 30 gal air compressor was inadequate. Yeah it works, but an oil less 30 gal compressor from your local big box hardware store does not put out the airflow needed to support mechanized plasma cutting. Especially if you’re cutting pieces that take more than 4-5 minutes. It cranks out hot air with plenty of moisture absorbed by the 300 degree air temps and barely keeps up. I bought an 80 gal 2 stage compressor to fix this problem, but I run other air tools and want a blast cabinet so the shop upgrade will be put to good use.

I live in Phoenix, I didn’t think it was humid enough to really worry about needing to invest much into air dryers. I was wrong. Moisture in my air caused inconsistent cuts, disgusting bevels in 1/8" or thicker steel and killed my nozzles within a few projects. I ended up buying a refrigerated air dryer and 5 micron filter after trying in line desiccant filters and smaller 5 oz canister style desiccant filters. They absorbed moisture and stopped working after a few cuts as they hit their abortion limits. Turns out the refrigerated dryer removes a ton of moisture but still not 100% on really humid days during our summer. I added a 1 quart desiccant dryer after the refrigerated drier to get whatever was left. Now I’ve got zero moisture but still have weird black specs and swirl marks on the consumables occasionally but not always … turns out the 5 micron filter doesn’t remove oil mist. You need a .01 micron filter. I picked up a Motorguard submicronic filter to eliminate oil mist. Now I have zero moisture and contaminants in my nozzles, they’re spotless inside and do not wear, zero dross, and practically 0 degrees bevel with amazing edge quality all the way up to 1/4" steel… but to the tune of about $600 after including hoses, adapters, and fittings.

Now I’ve got adequate air supply, but I’m over $3000 into the project and my plasma really isn’t up to par for mechanized cutting. It’s an older Harbor Freight model with Trifamet torch. Cutting 1/4" is so slow that it’ll hit the duty cycle unless cutting small parts. I’ve also spent dozens of hours learning Fusion, sheetcam, Mach 3, and Inkscape. The money and time invested into the set up at this point isn’t worth a couple bumpers. Or even a couple bumpers, suspension parts, a few dozen art signs, and bottle openers. I end up buying a Hypertherm with machine torch and cut quality and feed rate speeds are incredible. This is the quality I’ve wanted from the beginning, but I’m over $5,000 deep now.

At this point, I had so much interest from friends and family to make and sell stuff, I did just that. I ended up selling $4-5k worth of various parts, signs, and custom orders over the course of about 6 months. The profits paid for the table, plasma, and filters/dryers but now I’ve got a new problem: The frustration of owning a hobbyist table. Between the lead screws slipping or a bit of crap under the roller skate bearing throwing the cut off and ruining the work and material or warped metal or ever changing leveling issues as junk gets under the slot holders if you happen to move them… all of this causing contact with the nozzle and material because of no THC or tedious leveling and checking before every single cut, now I’ve got wasted materials and consumables literally every week as I try to up the usage of this machine. And admittedly, beyond what it was designed for.

So my personal opinion is that there’s a huge dilemma with the Crossfire.

For personal use, the time and money needed to learn and support the Crossfire isn’t worth it unless you’re building a complete rock crawler or something where you’ll cut thousands of dollars in parts for yourself. Maybe if you owned a small shop and needed it for limited use and had a background in CNC, it could be a time and money saver. If you’re starting from scratch, expect a steep learning curve and significant investment in supporting equipment.

The time and money needed to run a CNC business IS worth it! But the Crossfire is inadequate for the volume of even a small business. The Pro bridges that gap a little with a bigger cutting table and THC. But you’re still on a small hobbyist table with roller bearings and lead screws, and slow feed rates. The recommended production feed rate for 16g steel from Hypertherm and my current set up is over 50% faster than the Crossfire can even move.

Personally, I don’t regret purchasing the Crossfire or the path I took with it. I never would have randomly decided to dump $10k into a full size table with adequate plasma to start a business from scratch. The learning and growing process with the Crossfire put me into a position where I have the knowledge and need for a full size table now.

Every one has to start some were and that was a good way to find out if it was going to work out for you. I wish I would have started that way would have saved me a lot of time and money.

@OffRoadDevilDog excellent summary of the amount of ‘iceberg’ under the water. I think the types of things you cited are common for practically any new CNC technology - I know, I’ve tried a lot of them. I’m fortunate that I can justify this equipment because, to me, it’s all about learning and the expense and time is the ‘tuition’ to that learning. I have a very low expectation of getting a financial return on my investment.

Again, good job and I’m glad you stuck with it (both the CNC Plasma work and writing the summary).

I just purchased my new pro table. Should get it in August. I already have a Hypertherm 45 (not the XL version) I’ve set uo my cooler and filters for my compressor. What I don’t have is a machine torch for the cutter. Another question is what else do I need to get before the table arrives? I want the torch height controller. I didn’t see that it was included in the pro purchase. I didn’t see any place to ask questions except for the forums.

I would not be surprised if you can easily add THC to your order if you want it. IMO, any table as large as the Pro should have THC. I have a 2x2 and I’m adding THC to it (DIY implementation).

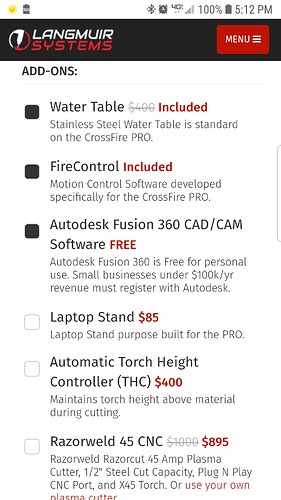

When you were ordering it gave you some add-on options. The first 3 that are blackened out which comes standard with the CrossFire Pro. The other 3 options are the ones that you would select the "Automatic Torch Height Controller "a $400 add-on.

Since you’ve placed your order already you would have to contact support and see if they can add it to your order. If they ship it separately it will cost you more for shipping. Hope that this helps! Good luck!

Got it, thanks. I also saw where you could add items to your order. What I didn’t see was a interface cable or a machine torch that would work with the Hypertherm 45. I located both online but would be nice if they were available at Langmuir. (or they had suggestions where I could get them.)

Oh, I plan on ordering the THC on Wednesday

Use mine everyday. No problems at all. Following the directions and the correct assembly is critical. Pick a plasma cutter that can handle your workload without problems. Wire it up raw voltage and you will be happy.

Also take the the time to learn Fusion 360.

We are all here to help.

Personally I don’t understand all the problems. Most are self inflected. This is not a buy and go into the sign business without a short learning curve. Sorry just my two cents…

Let’s go back to the other topic you started and see if we can make some lemonade🍋.