YESSS! I got it figured out and working after almost two weeks! I contacted Langmuir and they had me run several tests to see the voltages at my Razor Cut 45 CNC port. Upon completing all of the voltage steps (step-by-step instructions link for testing continuity between electronics enclosure and Crossfire table http://www.langmuirsystems.com/thc/guide#grounding-section, and step by step instructions for testing Exact Voltage Measurements here http://assets.langmuirsystems.com/file/THC+TROUBLESHOOTING+FLOW+CHART.pdf

I had no grounding issues or continuity between my electronics enclosure and table. That was an easy test with my multimeter.

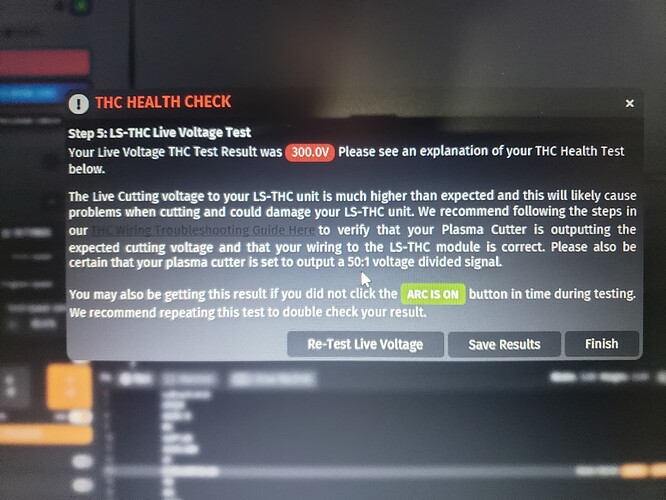

After running the next set of tests (multiple times) I found the voltages and then forwarded them to Langmuir. Each voltage test was significantly higher than they were supposed to be. Langmuir said they were twice as high as they should be.

Their suggestion was to contact Razorweld directly. This was a little disappointing since there wasn’t just some switch I forgot to flip, but contacting Razorweld was incredibly easy. I went to their website and found a link to email them, but I also found their direct contact number. In case you need it, the number is +1 253-859-6277 and they are located in Washington state (pacific time).

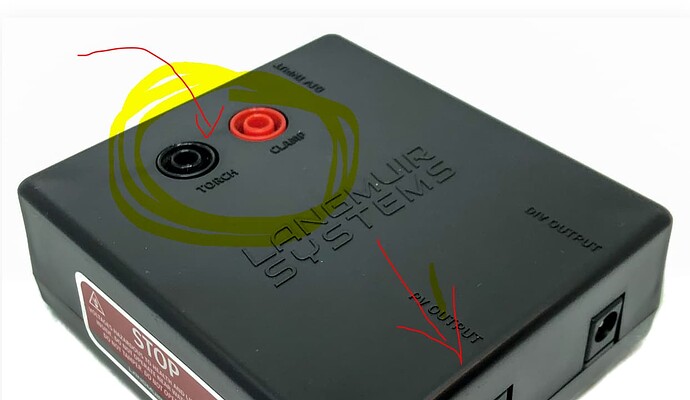

Upon calling, I got to speak with a human. As I was explaining my situation, he interrupted and said, “you must be calling about the voltage divider in your Razorweld Cut 45.” I agreed and he told me that I will have to replace the motherboard inside the plasma cutter to convert it from the 20:1 voltage divider to a 50:1 voltage divider. Either that or replace the entire plasma cutter. I asked about the cost and was told that they could send me a new motherboard for around $230 with shipping. THAT’S WAY BETTER THAN THE COST OF A NEW PLASMA CUTTER! I said, here’s my card number, please get it on the way!!

The new motherboard arrived about a week later. I had to tell a few customers that there would be a slight delay in their orders, but only a week or so… Anyway, I opened the box containing the motherboard and thought to myself, " Wow! You may have bitten off more than you can chew here Adam…" I decided to take a chance and see how hard this was gonna be. I took pictures of every single step I took including removing the screws and pieces of my Razorcut 45.

Although very nervous that I was gonna screw something up, I cleaned my hands and turned on some classic rock, and began unplugging and unscrewing every little connector as I came to them. Reassembly was reverse of removal and only had to solder two little wires from the CNC port to the new motherboard

You have to take the plasma cutter completely apart to do this modification, but don’t be scared, it ended up being fairly easy. Just glad that I had pictures to refer to. I cleaned up the internals of the machine as well. I couldn’t believe all the dust that was inside my Razorcut 45!

Afterward (the next day), I plugged everything back up to my plasma cutter and Langmuir Crossfire. Upon trying to fire the torch, all I heard was a “click” inside the machine. I began to freak out and called Razorweld. The tech guy helped help me figure out what the problem was. After explaining what was happening, he asked what my pressure reading was on the front of the Razorweld. Embarrassingly, I replied, “It’s at Zero.” I then realized that I had forgotten to turn my air back on!

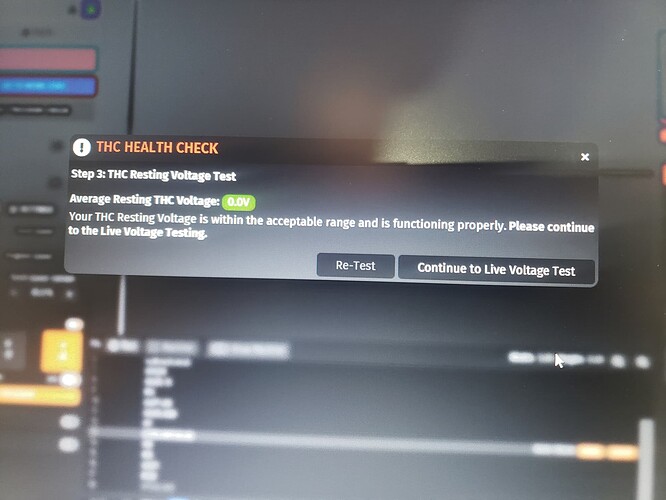

I ran the THC Test again in Firecontrol. The resting voltage ended up being 0.0volts. Perfect! I then ran the Arc-on test and the voltage is now running at 122.4 volts. Perfect again!! I ran a few test cuts and see that everything is working as it should!!!

Now just to perfect my drawings and do some cutting!

Big thanks to all who helped here on the forum and at Langmuir!

If anyone needs pictures of the steps I took to replace the motherboard, please let me know.