So i’m having a problem, my machine doesn’t seem to cut as hot as it was a few months ago, I’ve changed all the major consumables on the tip, and nothing helps, i got my cutter set at 60amps to cut 3/8, and it’s leaving top dross, and causing my cutter to hit it, and now has burnt my new tip because of it. I’ve cut a dozen or so of these 3/8 flanges without this issue and now It’s a problem. The dross seems to be messed up on initial pearce, and builds up.

my machine is a 1.5 years old, i’ve been using the plasma table sense april with no problems, and i don’t think it’s a machine issue with the table, i think its the plasma cutter.

Need more info. Tip size, consumables Original or aftermarket, air pressure, etc.

Air Pressure is whatever the plasma is set to from purchase, I THINK 40? could be wrong gotta check. Tips are all Factory NUTEC parts, i’m using a Nu tec 60AMP plasma machine, I purchased it from mac tools last year.

Not sure on tip size and stuff, because I don’t have any options to change my tip size.

https://weldingdirect.com/npnuplto601.html

heres all my parts

Send me some pictures of the torch with out the consumables on it and the consumables you have to motorman416@aol.com also send me some pictures of the plasma cutter front and rear. I think there are a lot more consumables to be had for that unit.

1 Like

Okay, I’ll send them over in a little bit, I had trouble even finding the ones i got now, So if there’s more, i’d be super excited if so.

Mechanic will hook you up.

Here’s what’s going on. I’ve been trying different heights, different speeds, I’m maxed on amps @60, and i’m running 20ipm, its building up too much on top, then starts touching the torch, and everything is messed up from there, Idk what to do i’m pulling my hair out on this and i’m wasting materials. any help is appreciated.

I’ve tried increasing the air pressure, didn’t affect anything, tried slowing the machine down to 20, i’m at a loss. I can cut small stuff no problem, I was cutting 1/8 last week and it was like butter no issues.

Like I said before, pictures! Then a phone call.

I sent you a bunch of pictures before I posted here! Check your email!

Never got them. Try it again.

Looks like my cuts, when I dont have a good ground contact.

I re sent the email again just now.

So I have been frustrated like you for the last few weeks, same crap, cuts…don’t cut…ruins steel.

I added a poor boys air dryer to go with my other air dryer, did not seem to help.

This week a new swirl ring came in at the welding supply store, I have had this plasma cutter 2 years and I have never changed the swirl ring before, this morning I cut some 1/8" aluminum and it cut flawlessly. Beautiful cuts. I hope all my problems are behind me and I hope you get yours figured out sooner rather then later. Not saying this is your problem but may as well start at the beginning.

2 Likes

See the problem i think started when my old employee burned through the tip so bad he melted the swirl ring, But sense then i’ve replaced everything that can come off the torch, next step i think would be to replace the torch its just expensive…

I got in the habit of changing out the electrode every time I took the torch apart, just to make sure it was not the problem. Even if the tip looked good I would change it, now I think I own more hafnium now then the entire country of Hafistan.

1 Like

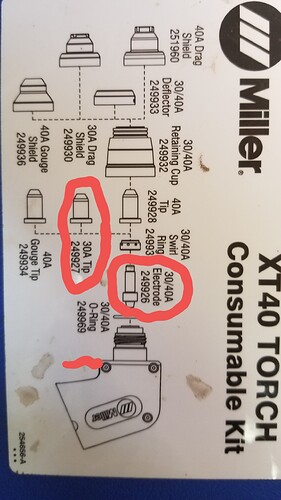

Which part is the electrode? I usually change all of it everytime too, but it’s a 100 bucks everytime

That is crazy dude, $100 to change them? They are consumables not collectables.

Changing consumables for my torch is changing out the electrode and the tip. They are the wear parts. Everything else is along for the ride and last quite a long time. Swirl ring, drag shield etc is maintenance.

It cost me 5.33 for a electrode (3 for 15.99) and $3.50 for a tip (3 for 10.99). This is for Miller genuine parts, I don’t know of any knock offs for Miller.

You should not be paying $100 to change your consumables.

I’ve only found one website that sells my plasma cutter parts, and The outside tip is 40 dollars, and the electrodes you gotta buy in a 5 pack for 20, and the other part of the consumables for the tip are another 20. then with shipping is almost 100 bucks, and i’ve done this twice just trying to figure out whats wrong.

Apparently you didn’t get the email, you should call me. That being said, first thing you should do is change out that torch for one that you can get consumables for.

I have been cutting this part for several months. Now all I can get is a mess. I have changed consumables with no success. Error during cut says lost connection before torch moved.