I have a Hypertherm 45XP but have no familiarity with the SmartSync system. That being said, that type of cut will happen if:

- the torch is fouled somehow (I had flecks of aluminum between the nozzle and the electrode that kept causing the intermittent inability to cut).

- Work lead is not getting a good purchase

- Consumables are screwed on too tight. You only want finger tight. Hypertherm recommends backing off about 1/8 of a turn.

- Torch is too high off the surface of the metal. I assume you are using THC. Are you noticing the torch rising during those times?

- You will not get any better results going past 100 psi unless your system is having trouble keeping up with the air demand. Was this during a time when the air compressor cycled?

- Are the consumables in the correct order?

- Make sure the torch is not being held/clamped on any of the consumables.

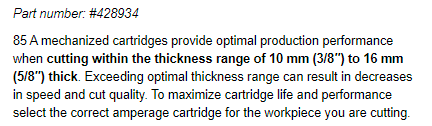

Hypertherm suggests that you are not in the range of optimal thickness for that torch cartridge:

Edit: I guess that torch part has all of the consumables and really does not have lots of different choices for thicknesses of metal. Pretty cool. If it is on a smart torch then everything is as it should be. But, if it is not a smart torch, you need an adapter. You probably know more of what I am saying than what I do, at this point.

EDIT: This topic is now being discussed at the following thread. OP requested the changed location: