I have a hypertherm 85 sync. My plasma cutter wont cut consistently. The ground is good. Air compressor is 80psi. New tip. Compressor is hooked directly to the table. Running at 45amps

What are you doing for moisture in air?

Post pictures of consumables will help also?

@Wiggy123 Please don’t start multiple threads. You have posted the same message on two different threads. Two responses on your other thread and both before you started this thread/topic.

@Wiggy …so as @DonP mentioned…what are you doing for moisture control…?

you say you have the compressor connected right to the table…you mean your compressor is right beside your Plasma…

we ask that because the picture looks like possible moisture is preventing good cutting…

how big is your compressor and do you drain it all the time?

also is your plasma clamp on the metal?

What are your settings you are using/

WHat gauge of metal are tyou trying to cut.

the more information you provide the better we can help.

First the torch height is to high. Second your using the wrong cartridge it should be the 45 amp one.

I’ cutting 12 guage steel. I am grounded to the steel plate. I do not have a dryer, and have no idea if theres any water in the compressor

I tried deleting the other ome, but didnt have a good enough signal

Understood. I will change the title to (MOVED) and give this thread address. This thread is actually under a more appropriate heading.

So the first thing to do is look at the bottom of your compressor and see if you have a valve and open it up. Stand back because it might be a rusty water mess on the ground. If no value you should put one in. Make sure you release all tank pressure prior to removing the bolt on the bottom. GL

After getting water out of the compressor you’ll still need to add some type of moisture control. I have tru-flate and M60 but I’m sure you’ll get a lot of information from others on complete systems of removing water. You can’t have too dry of air.

The corollary to this is that you will NEVER have dry enough air coming straight out of a compressor.

if you do not know…then I gaurantee there is water in your compressor.

@DonP stated there is a drian on the bottom of every tank…and they need to be emptied every day you cut…not doing this make water build up…and as you drain the water it wil lbe rusty and if emptied to quickly it will freeze the drain port…so do it slowly.

Make sure there is no more water in the tanks.

next…you need to know how dry your air is and to do that you need a few things…

you need to install a beaded desiccant dryer and a filter, like a motorguard filter just before the plasma cutter.

the beads (which can be dried in an over for use over and over) show you how moist your air is as they absorb moisture as the air passes through them.

the motorguard filter filter is your last line of defense from dirt in the air and possible last moisture.

also keep in mind you need to reduce 1/4" fittings and quick release couplings …they restrict air flow.

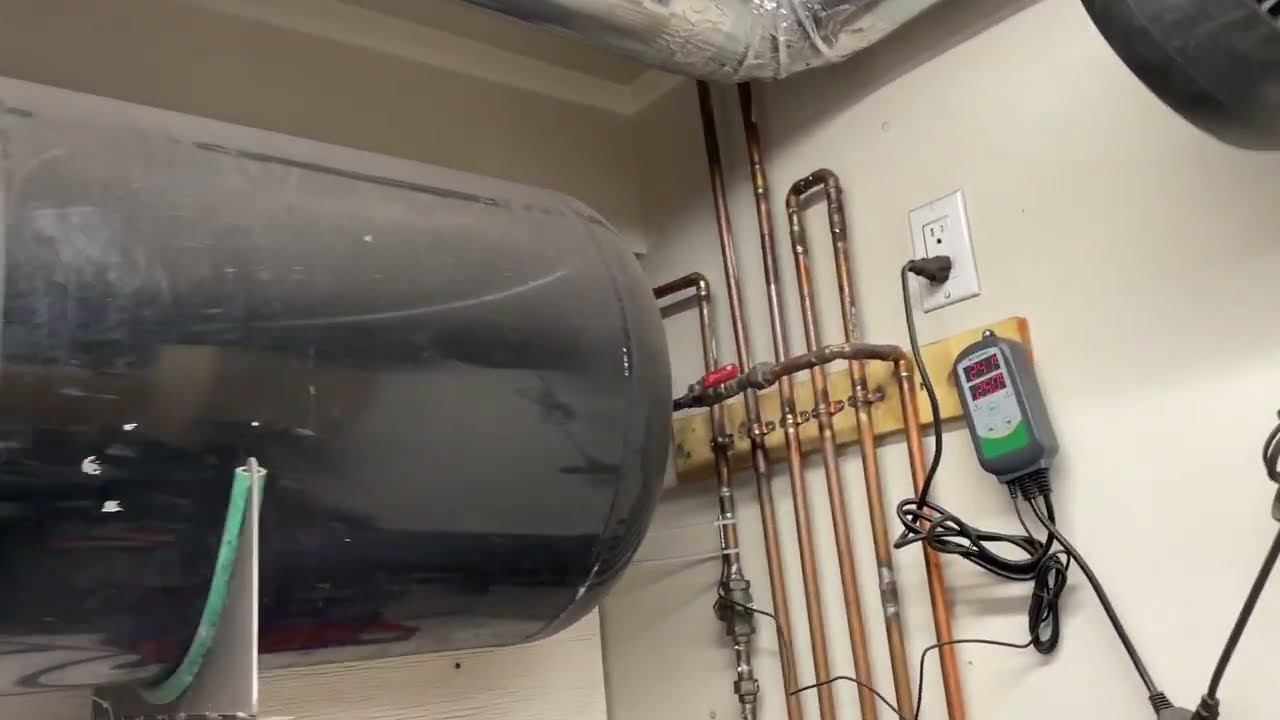

so here is my system…it is extensive…but it covers the basics of moisture removal…

also pay attention to what @mechanic416 says about your torch tip…George has forgotten more than most of us will ever learn about plasma cutting…