Using fusion 360 for post processing, not getting a pierce delay. I put it up to 4 second for testing purposes and it definitely isn’t waiting 4 seconds. I’m not seeing a pierce delay in the g code either. Trying to cut 1/4" so I’m really noticing the lack of pierce delay. Any ideas?

post the g code lets see what is going on.

It’s in there. G4 P0.5. That’s a .5 second delay after the M3 torch fire command.

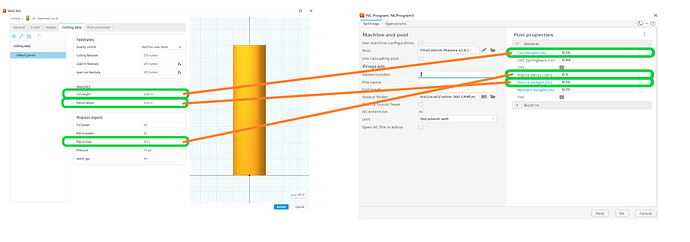

That makes sense now, I was thinking it should say (Pierce Delay). Is there a breakdown on the g code lines so I can know what each line means? Also I’m pretty sure I figured out why I was getting .5 second delay instead of the increased delay I was setting it to. I was inputing the delay into the torch settings when I would build a torch profile for the different materials I would be cutting. I did see the pierce delay setting again in the post processing screen, it was at .5 seconds… What is the purpose of these settings when you build a torch profile if they don’t actually affect the g code?

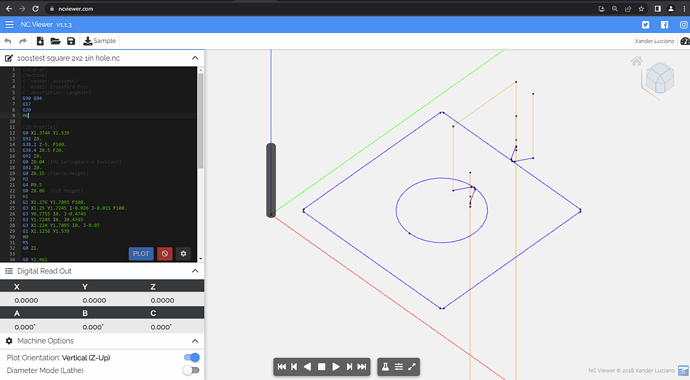

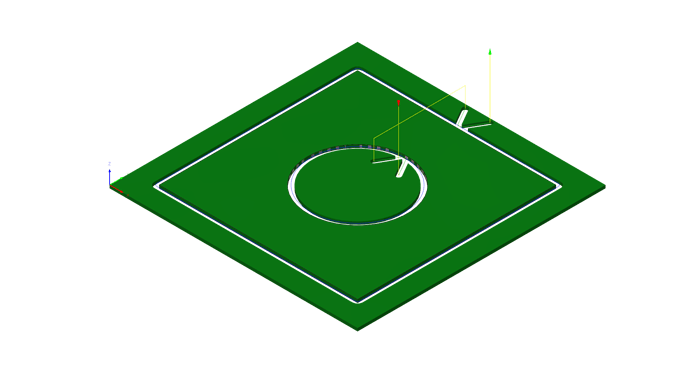

here is a bit of a break down

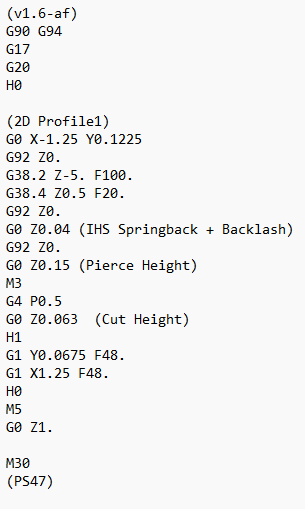

here is the g code for this

Here is that code where I explain each Line that cut out the middle circle.

(v1.6-af)

(Machine)

( vendor: Autodesk)

( model: Crossfire Pro)

( description: Langmuir)

G90 G94 (Origin Point Location, Feed Rate Unit Per Minute “F” Below )

G17 (Plane Selection XY-Plane)

G20 (Unit Selection: Inches for Unit Length)

H0 (Deactivates Torch Height Control or THC)

(2D Profile1)

G0 X1.3744 Y1.539 (Rapid Positioning: Move From Origin to This new Position on the X-plane &Y-Plane)

G92 Z0. (Set New Origin for Z, Current Z Position to Zero )

G38.2 Z-5. F100. (probes towards a target and stops on contact, signaling an error if it reaches the target position without triggering the probe, Target Position of 5inches, Feed Rate 100 inches per minute. The trigger is the IHS )

G38.4 Z0.5 F20. (probes away from a target and stops on contact break. An error is signaled if the target position is reached without triggering the probe, Target Position ½” or .5” , Feed rate of 20 inches per minute The trigger is the IHS)

G92 Z0. . (Set New Origin for Z, Current Z Position to Zero )

G0 Z0.04 (IHS Springback + Backlash) (Rapid Positioning: Move From Origin to This new Position on the Z-Plane))

G92 Z0. (Set New Origin for Z, Current Z Position to Zero )

G0 Z0.15 (Pierce Height) (Move or position Rapid Position to the Pierce height of .015” )

M3 (Turn Arc ON)

G4 P0.5 (Pierce Delay or Dwell for .5seconds)

G0 Z0.06 (Cut Height) (Move or position Rapid Position to the Cut height of .06” )

H1 (Actives Torch Height Control or THC)

G1 X1.276 Y1.7095 F100. (Linear Movement to this XY-plane Position at 100 inches per minute )

G3 X1.25 Y1.7245 I-0.026 J-0.015 F100. (Arc or Circle Movement to this XY-plane Position at 100 inches per minute )

G3 Y0.7755 I0. J-0.4745 (Arc or Circle Movement to this XY-plane Position)

G3 Y1.7245 I0. J0.4745 (Arc or Circle Movement to this XY-plane Position)

G3 X1.224 Y1.7095 I0. J-0.03 (Arc or Circle Movement to this XY-plane Position)

G1 X1.1256 Y1.539 (Linear Movement to this XY-plane Position)

H0 (Deactivates Torch Height Control or THC)

M5 (Turn Arc OFF)

G0 Z1. (Move or Rapid Position to the Retract height of 1” )

G0 Y2.461

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.15 (Pierce Height)

M3

G4 P0.5

G0 Z0.06 (Cut Height)

H1

G1 X1.224 Y2.2905 F100.

G3 X1.25 Y2.2755 I0.026 J0.015

G1 X2.25

G2 X2.2755 Y2.25 I0. J-0.0255

G1 Y0.25

G2 X2.25 Y0.2245 I-0.0255 J0.

G1 X0.25

G2 X0.2245 Y0.25 I0. J0.0255

G1 Y2.25

G2 X0.25 Y2.2755 I0.0255 J0.

G1 X1.25

G3 X1.276 Y2.2905 I0. J0.03

G1 X1.3744 Y2.461

H0

M5

G0 Z1.

M30 (End of Program)

(PS100) (Program Speed 100 ipm)

Some G code information

I was wondering the same thing some time ago and started a post at the autodesk.

maybe one day they will inform the post processor ?

It would be really nice to have different profiles that were dialed for different materials. Guess I will just have to write down on my note pad for now.

You can do that in Sheetcam. Create a tool for every type and thickness of material.

I think I will look into sheetcam, thanks.

In Fusion everything but the pierce delay and cut/pierce height has to be added at the end and the other settings can to saved.

SheetCAM is definitely easier for a lot of folks.

I just hate to lose the parametric connection between manufacturing and design by moving it to Sheetcam.

You may lose 15 seconds updating those few pieces of tool data in Fusion 360 but if you have to make one design change in SheetCAM you have to backtrack to your CAD software and lose time too.