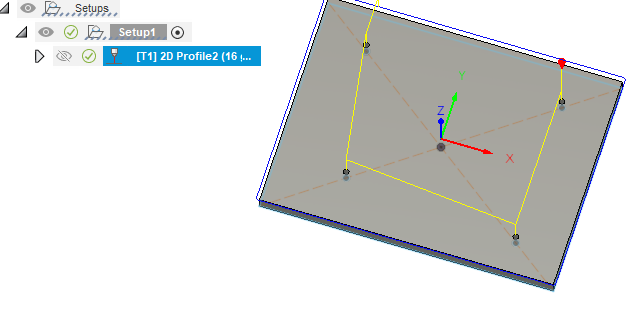

I decided to investigate this further. I started with the assumption that Fusion CAM would try nearly any contour that allowed the kerf width of your tool. In this case my tool was for 16 gauge steel and it was set at 0.045 inches.

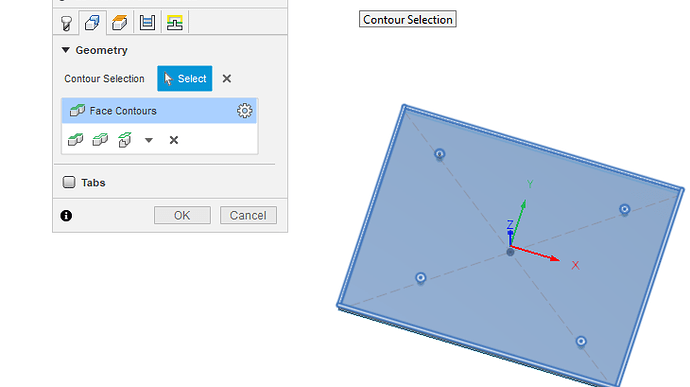

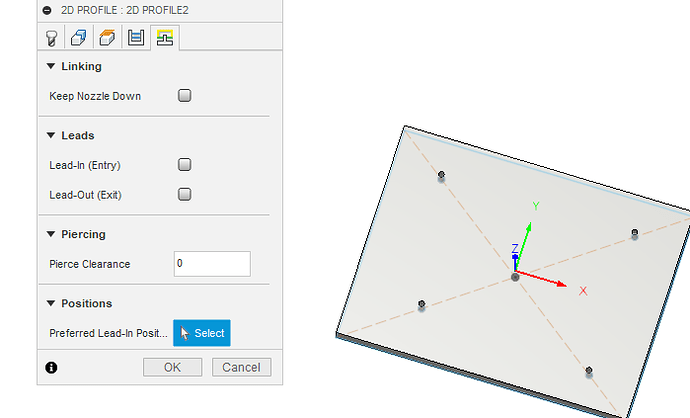

I just made a basic shape and put four holes: three were sized 0.045 inches and one was 0.05 inches. I extruded the part. I picked the contours by picking the body and removed lead-ins, lead-outs and pierce clearance. The result: it only picked the 0.05 inch hole. By process of elimination, as @TinWhisperer suggested, a micro addition is needed. I changed all holes to 0.046 inches and it worked!!!

Now removing the leads and clearances:

Result: