The die is still moving around right?  I put my name on the list.

I put my name on the list.

I sent a couple out. I can print up a couple more if folks are finding the current availability too limited.

Oh wait, I read the thread until the point where the 3D printed die made just a conical dimple. That is why I signed up for the metal one. I’ll read more messages to see the improvements on the 3D one (I do have a 3D printer) but stay on the waiting list for the steel one just in case

I checked it and I’d prefer to use the machined steel one. I can pay for it and even send a pre-paid label to the guy before me if it helps. Let me know (I know, right now I am pretty far down the list)

That’s not the case with the gen 2 version of the 3D printed ones at least with the ones I’ve made in resin on an SLA printer. It creates a flat shelf for the drain washer to fit nicely. If you have a 3D printer try printing it with 100% infill so it’s solid. I think PLA or ABS that isn’t solid may deform as you’re squeezing the die halves together. Solid ones should exhibit less deformation and create a flatter bottom. I’m pretty sure that’s why my resin ones were flat - very solid parts.

Table parts should start arriving here shortly(Or so I am told)…

I have a buddy with a 3d printer locally. Hopefully, he has the correct material to print me up a couple of the MOD2’s.

What do we consider to be the best material to use now? I’m assuming it’s 100% infill no matter the material?

Looking for your thoughts… TNX

I believe that’s the case. You may get away with a use or few without noticeable deformation when it’s got 50 or 100% infill but it might be deforming while being compressed and you don’t see it visibly due to the elasticity of the print. That could be why people report some rounding of the mating surface in the pan. A solid part will minimize that with not a huge extra cost in filament although print time goes up. For resin, it’s always just easier to go solid and the print time is unaffected by fill percentages.

I have printed one in PetG and it seems to be plenty strong, 95% infill. If anyone else needs one let me know and I can print a bunch and drop them in the mail.

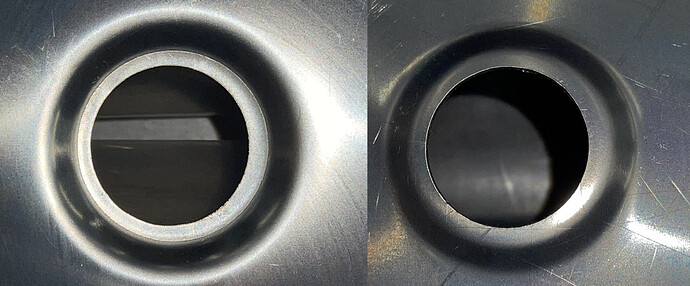

I just received 2 of the 3 shipments for my Pro table. The frame and pans. I had already printed the mod 2 die and wanted to share the results of its use.

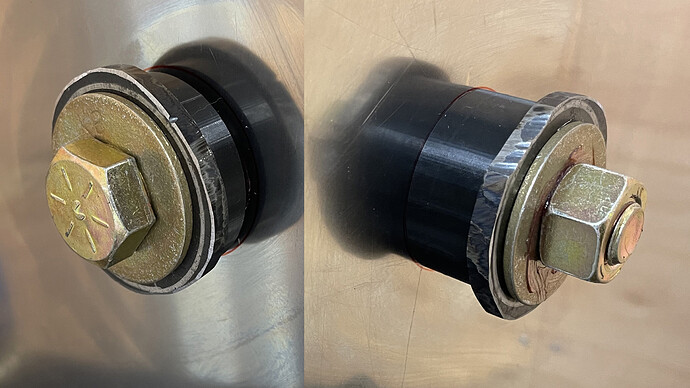

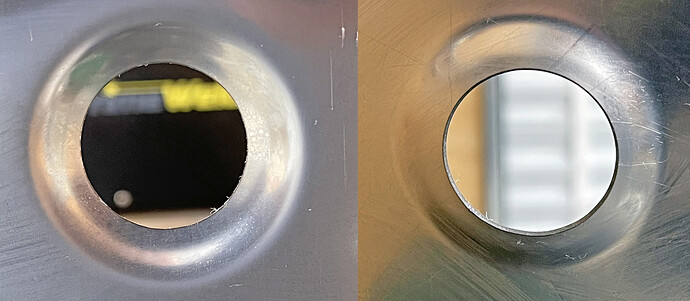

I used a couple scrap pieces of 1/4" plate that were large enough to cover the entire surface of the die to prevent any deformation and drilled a 3/4" hole for the bolt. I greased the surface of the pan.

After pressing, the results were as expected after reading previous posts. Nice dimple, but absent of the flat area for the drain to seat against.

I put a 1/2" bolt through the pan hole with a stack of washer on either side. The diameter of the washers matched the flat area of the die that did not get pressed in properly. I used grade 8 washers at the bottom of each stack because the first attempt with mild steel washers resulted in them bending.

I was very pleased with the end result. It flattened out the bottom of the dimple creating a nice area for the drain to seat against.

Just thought I would throw this out there for a possible fix for the conical results of using the 3D printed dies.

Hoping someone can explain how to open the dxf files in fusion 360 so I can convert to STL. I have a 3D printer, but I am still relatively new to fusion. It keeps giving me an error message when I try to insert or open the dxf. My table is shipping soon and I’d like to have these before assembling. Could turn a set on the lathe but it seems the printed set works fine. Any help would be greatly appreciated. Thanks

Download the files from the following link but make sure after you do that you change the .DXF to .stl because they are stl files. I believe this forum won’t allow inclusion of .stl file so folks have to trick it by changing the extension to DXF.

Got it, thank you. I didn’t realize that they were already in the stl format.

Who has the metal Mod 2 now? Haven’t seen any movement in the spreadsheet for a while.

Great day everyone, I will receive box 3 of 3 today! It has the water pans in it. Just queries on whereabouts the steel mod2 die might be haven’t seen any spreed sheet updates?

@Toddc I’d like to buy one of these from you. Can you message me.

Are these still around? got my water pans, would like to get them ready before the rest of the table shows up.

Hey Marshall,

The original steel die and punch I made was shipped to the first person in the spreadsheet many months ago so I don’t know where it is currently. I think people are having luck using the 3d printed versions of the Mod 2 design especially if the item is printed with 100% infill. Looking at threads above I even see members offering to send these to anyone requesting so I would probably take them up on it. Hope that helps.

Dan

Hey Todd

I cant beleive how helpful all you guys are in this forum. you dont see help like this now a days.

Can I buy two sets off of you, unless one set will do both pans of my pro table.

Please let me know

Thanks

Jason

Send me a PM with your address, I always send 2 now because they eat themselves in dimpling. I will start a set printing now.

I’m on the list have been on it for a while wondering what the status is on the list?

Doesn’t seem like it’s been updated much. Looking to get these soon as my water pan and table parts are here in my hands. Any info would be appreciated thank you