Glad you got her nailed down Krylon. Now you can get to enjoying it more. And the problems you’ll face are each a learning experience as with many of us. Have fun!

This is why adjustable hard stops would be so useful. Have the hard stop hit on a flat surface of the bearing block instead of letting the bearings themselves suffer the abuse. Then it really wouldn’t matter if you hit them at 300ipm, you’re unlikely to do any harm to anything, and if something gets out of whack because you got hung up on a tip up, just home back to the hard stops and as long as your sheet didn’t shift you should be able to restart the program and be in the EXACT same position, within a thousandth or two. How could that NOT be a useful upgrade?

I just wanted to add that setting a repeatable, square, but adjustable if needed, home postition has a lot of other benefits.

Say for example you wanted to index a sheet a specific distance; a 3D printed carbide scribe tip holder as a stand in for your torch held in your torch mount would allow you to set the sheet corner position very precisely, and since you can square your gantry as precisely as you have patience for, you can also square the sheet using the same tool. Before or after you cut your first part of the indexed part, mark a fine line with the scribe on the sheet at both edges at the indexing distance (as well as an X axis reference), then use the scribe at the other end to line it all up before finishing your index cut.

Someone with a good eye and patience could probably achieve +/-.010" or better alignment using this method, as the carbide scribe would allow for very precise lines, and you could be assured of the machines squareness. You wouldn’t even have to be concerned that the scribe and your cutter tip are perfectly aligned, as you are only concerned with the offset of the sheet, not the two tips relationship to each other.

Another scenario. Say you have a shop mishap that damages one of your Y axis bearing block holders, or do some modifications in the future. Instead of being worried about distances being super exact, as long as things are square enough for the bearing blocks to mount and run true, you can easily dial back in the gantry squareness.

Full agreement there. A roller skate stopper , mounted to a plate would work. It’s already threaded for mounting… gonna have to look into this more…

Or how about just a plate bent 90° with a nut welded to it and the head of a socket head cap screw to use as the stop. Once you have it adjusted where you want it, lock it with a jam nut. I’ll draw some plates up tonight and post them in case anyone wants to do it but isn’t sure what I’m talking about.

Sorry, I got distracted last night cutting body armor for my Crossfire Pro.

A splash shield for the controller and leadscrew protectors. All files downloaded from Fireshare and cut from 16ga.

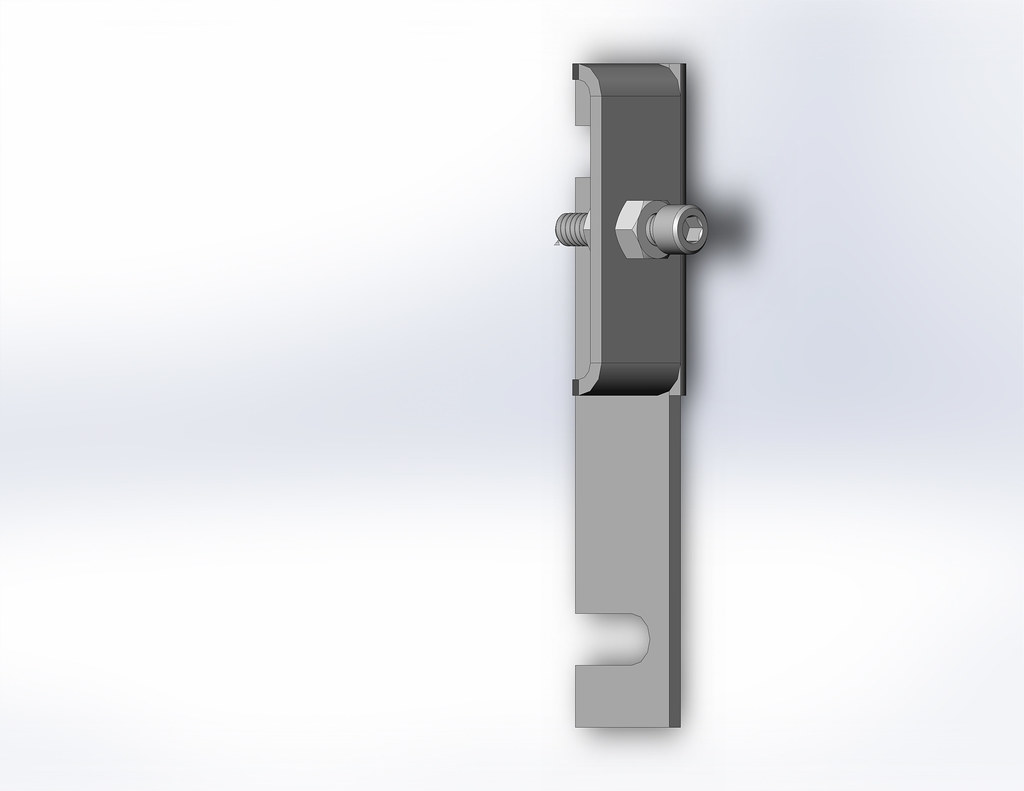

Found some time to throw my thoughts together into CAD. Here’s what I’d do as the first step to adjustable end stops. If this in 11ga (braces welded) and a 1/4" bolt isn’t enough to withstand the stepper motors hitting it, I’ll make it from something thicker. Also, I’m likely to use a rivnut instead of welding a nut on, just because I can.

Why not a polyurethane bump stop? The stepper motors wouldn’t have enough power to compress them and would be a softer stop.

More expensive than a bolt, but either should work fine if you’ve got the space. Keep in mind, a softer stop means there’s more flex in the zero, and heat and cold will effect the durometer of the polyurethane.

There would be very minimal flex and it holds its shape under pressure. It would be more expensive though a couple bucks compared to a few cents.

You can get them for closet and pocket doors. They aren’t too large, but fairly solid. Rubber feet off of kitchen countertop appliances would work too…![]() (don’t tell the wife)

(don’t tell the wife)

I like the mount. All of my mods use existing bolts also.

Look up “Bump Ons” Used in cabinets.