Fairly new to this cnc plasma world and getting my setup dialed in.

Bought a Titanium after watching reviews and got the stock torch cutting which I would say was decent. Dross was the biggest complaint if I had any, especially on holes. Had to really work at chipping it away or in some cases would have to grind it away in a few spots usually in the lead in area.

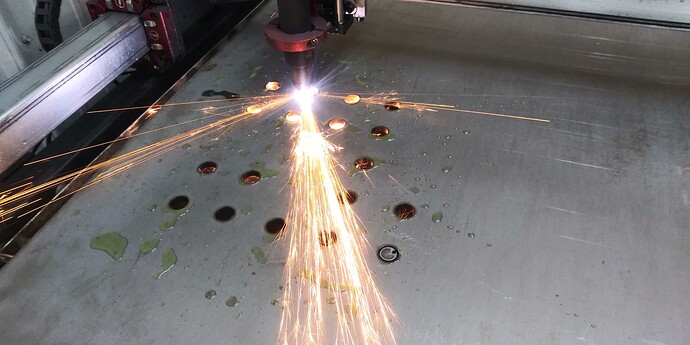

This is primarily on 3/16 steel. Cutting at 40amps with a speed of 30, cut height of .030" - tried faster and higher and much much worse. This seemed to be the sweet spot. Cut a bunch of corvette suspension parts I used to make and sell by hand - and was pleased with the results.

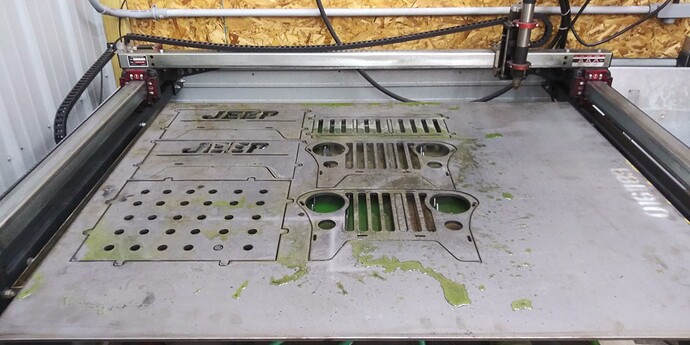

I wanted to get into signs and had a girl want 4 of them. Knowing the torch I had with the stock unit was too large I bought a PMT-60 thru forum member with the finer tips.

Got the unit and tried it on the 3/16 with a 40amp tip. The cut quality all things equal was not anywhere near as good. played with the parameters and nothing seemed to work. At cut speed of 50 it wouldnt even cut all the way thru.

I have been reading on there a lot and like most dont want to spend a zillion dollars. But after having another 500 bucks invested and wanting good quality - I decided the next best thing was to invest in a dryer system as many built out of copper. So I picked up 5 sticks of 3/4 and built one with my boy who was home from Med school. Fun little project joking the entire time it would be a waste of money, but oh well. Mine you before I had only one water seperator on the 60gallon compressor. COnsequently I have drained it before and have never seen an sign of moisture. So we built the dryer, and tucked it on the wall - looks pretty cool actually. Built it with 3/4 and 9 straights of 5ft tubing along with connectors between about 3 5/8 Center to center. Figure I have around 50ft of tubing plumbed it straight to the plasma.

Loaded up the same program and ran a piece. Immediately the dross was improved and what was on there came off with ease. This was at the 30 speed and .030 cut. I moved up and eventually found that 45ipm was the sweet spot with .060. I cut a shape used for a wishbone mount with curves and two holes - so it gave a good representation of different cuts.

I am amazed that the dryer system made that much of a difference. I tried to drain the tubes after playing all night and the compressor running several times and it never showed a sign - but there is a VERY noticable difference. So I am a believer bigtime of the need to remove moisture.

I know what all the seasoned people are thinking…what about filters. I bought a series of filters and desicant in the last one to be plumbed into it, and lastly a motorguard 60 filter. Figured I was already this far why stop.

The long and short of it is wish I had done more research on this aspect before. But I have another 500 in torch capable of smaller cuts, 400 in copper system, 250 in filters - so another 1150 in items I didnt orinally realize. All my fault and no complaints. Just pointing that out for newbies to realize. You WILL needs most all of the above and it makes a huge difference.

The most telling part of the above was when the night before I tried to cut at 50ipm and it would even cut all the way thru, To the next night cutting the same 50ipm and it cutting like butter. Only difference was the Cu system. Odd thing is no moisture seen in the collection tubes yet. But it must clearly be there.

Excited to see what the additional filters yield. I would say I am 90% there.

Thanks everyone!