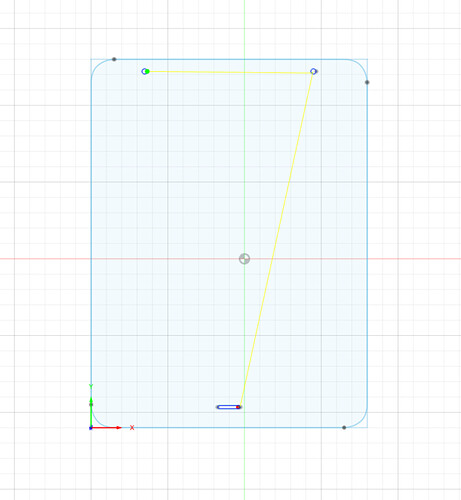

Doing a project to cut three holes in a piece of alumnum sign blank. First two cuts are fine third one gets error when I hit retry cut, generate, start it cuts the third hole fine. What am I missing?

(v1.6-af)

(Machine)

( vendor: Miller)

( description: Plasma Cutting Machine)

G90 G94

G17

G20

H0

(2D Profile1)

G0 X9.5931 Y1.3408

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.13 (Pierce Height)

M3

G4 P1.

G0 Z0.06 (Cut Height)

H1

G1 X9.7166 Y1.3598 F100.

G3 X9.616 Y1.4408 I-0.0983 J-0.0192 F100.

G1 X9.6035 Y1.4411

G1 X9.3949 Y1.4409

G1 X8.9775

G1 X8.5602

G1 X8.3657

G3 X8.3091 Y1.4259 I0.008 J-0.1446

G3 X8.2799 Y1.3802 I0.0615 J-0.0716

G3 X8.2659 Y1.3366 I0.4155 J-0.1574

G3 X8.3686 Y1.2379 I0.1006 J0.0019

G1 X9.6159

G3 X9.7166 Y1.3598 I0.0018 J0.101

H0

M5

G0 Z1.

G0 X14.4589 Y23.1824

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.13 (Pierce Height)

M3

G4 P1.

G0 Z0.06 (Cut Height)

H1

G1 X14.3647 Y23.1002 F100.

G3 X14.5458 Y23.0513 I0.1253 J0.1045

G3 X14.4345 Y23.3604 I-0.0557 J0.1546

G3 X14.3645 Y23.1 I0.0557 J-0.1546

H0

M5

G0 Z1.

G0 X14.3647 Y23.1002

G0 X3.5332 Y23.2059

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.13 (Pierce Height)

M3

G4 P1.

G0 Z0.06 (Cut Height)

H1

G1 X3.6582 Y23.2088 F100.

G3 X3.5779 Y23.3469 I-0.1613 J-0.0013

G3 X3.4693 Y23.3678 I-0.0821 J-0.1343

G3 X3.3672 Y23.3091 I0.0203 J-0.1536

G3 X3.3314 Y23.189 I0.118 J-0.1005

G3 X3.391 Y23.0787 I0.1545 J0.0123

G3 X3.5112 Y23.043 I0.1005 J0.118

G3 X3.6214 Y23.1026 I-0.0123 J0.1544

G3 X3.658 Y23.2088 I-0.1154 J0.0993

H0

M5

G0 Z1.

G0 X3.6582

M30

(PS100)