When you say plunge are you referring to pierce? Or is this a Z-axis feature where you can control the speed it goes down to the plate after the pierce delay? I’m not trying to be pedantic, but I can’t find a plunge delay, only a pierce speed and height. Is this a feature in FireControl or a Fusion360 CAM setting I’ve missed? Because you may be onto something.

Yes, from the pierce height to the cut height. That said, I am pretty new to this as well so do not quote as gospel. I was told that the plunge rate in Fusion 360 is pre set and I did not have that issue with F360. I now use Sheetcam for post however because I find it more intuitive and easier to use for me, and the default there is way too low. But my issue was very similar, it would blow a hole and then quit. In sheetcam it is Plunge rate, not delay, it is similar to cut speed just up and down instead.

again, told there is no problem with plunge rate in F360, could there be something slowing down your Z axis?

Ok, so I finally got some time to continue the process and when I ran the test square it gave me the error that says your delay is either too long or too short. This particular error is the one that got me to test in increments up to 5 seconds and settle on 2 seconds. But, it’s somewhat inconsistent because sometimes it fires and doesn’t pierce and sometimes it just doesn’t fire.

I’ve been playing with SC and I own the paid version, but I’m hesitant to add in more variables. It might solve the problem, but I’d like to figure out what is happening to make it act so tempermantal.

The Pierce delays only .6 in that program.

Being your machine has some weird latency I’m not sure what’s up.

You might just have some oddly long delay on that machine?

I’ve gotten good results from the machine. And it’s firing from time to time.

Is this something that Langmuir might be able to help with or am I hosed?

Is this just something I should give up on? I don’t really want to sell my gear. I’d be happy to buy a plasma cutter from harbor freight today (it’s Black Friday after all) but not if it’s going to keep giving me problems.

I would suggest testing it with another machine.

That suggestion makes sense and I get it. But I don’t actually have an extra one lying about and if I buy one I’d have to open it up and void the return. I’ll probably call Langmuir on Monday to see if they have any technical suggestions before I drop $1000 on a machine.

I do appreciate the help.

@langmuir-reilly Could you let me know how to proceed on troubleshooting this…short of buying a new machine. I’m not saying the machine is fine, but I’d like to eliminate any other problems before I buy a second machine. And, I’d like a suggestion on what the best one would be in these circumstances.

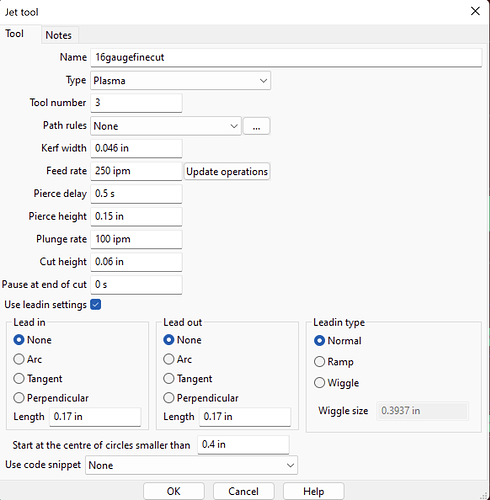

I had nothing but headaches with post on F360 and post. Love it for drawing. I suspect a problem between keyboard and user. I now save the drawing as a DFX and open up in Sheetcam and do my post there. For me it works much better. You don’t have anything to lose by going there. I find more control on where it cuts for me. YMMV. I would give it a shot in Sheetcam, takes all of five minutes to set up the post and once I fixed the plunge rate I am getting good cuts. I play around with the lead in a bit for different areas. the nice thing I find with it is you can set up different cut parameters for different areas of the sketch. Probably can do this is F360 as well, I just found it very intuitive in sheetcam. there are six settings on the left you need to enter. This one is for Hypertherm and 16 gauge Fine cut. I am told you can’t set the delay more than .5 seconds but I reduce it in File share as I was told here to 80%. Need less for the thinner material.

Yeah, I’m def going to try this. I just have to watch a couple hours of tutorials on how to run the post on a layer. I tried to get it to work and it gave me the error it gives when you only have the header G-code and didn’t run the post right.

You guys are the best, seriously. I’m constantly amazed at the generosity of the people here to take time out of their busy lives to help total strangers solve problems of their own making.

I can’t thank you all enough.

Arc light has great video on YouTube.

SHEETCAM BABY!!! Ignore all the divots from previous attempts. I’m getting tired of spending cash on virgin plate.

Anyway, it was in fact a CAM/CAD issue. Not sure what exactly, but as soon as I tried in SC it started working really well. I’ve got some settings to work out yet, but this abates my frustration enough to keep me going.

Again, thank you to everyone who chimed in to help. Even if the suggestions didn’t work, just going through the process with you guys made me think less that I was nuts.

If you do get a chance to post your Fusion 360 file it would be interesting to see what error was made in the CAM portion.

That’s awesome you’re getting some success.

Which would be most helpful, the f3d or the dxf or the nc file?

Thanks. I’ve still got some way to go but at least I’ve got a part for my lady’s earring tree. I’ll post the files tomorrow and some pictures of the finished project after I nickel plate it.

f3d you used to produce the G-Code that failed.

I wouldn’t mind investigating.

I’m interested in the nickel plating process that sounds really cool.

Hey William,

I’m more than happy to help with this!

Would you mind sending us an email regarding this? This thread is already quite long and full of useful information, and I don’t want to be redundant. Either Aksel or I will be able to help you there, and then you’ll have both this thread and an ongoing ticket with ideas to try. Thanks!

email sent. Thanks for getting back to me.

O would suggest pulling the plasma cutter off the table and try to rapid cut or pierce with it manually. Perhaps ur plasma machine dont wanna make repeted fast cuts. Weather it the relays or otjer switching mechanism inside the cutter itself that wont change fast enough to keep up with the cnc controlers fireing orders.

Make sure you follow up on this thread as to what fixed your problem please

If I ever get it fixed I will for sure. Waiting on two new plasma cutters to be delivered right now. First one gets here Monday. That way I know it is or isn’t a problem with the power source. Also ordered several different torches and I am going to braze the work lead to the table.

Sometimes you gotta bring the mountain to Mohamed.