I’ve been using Fusion 360 for over 3 years. Is it just me or is this program getting more and more difficult to use? I have been having non-stop issues with it loading, hesitating, buffering, locking up, etc etc etc is it just me? like I said I know what I’m doing with this program and using it for years it’s just getting to be a real pain in the ass!

It’s not just you. Between the hardware resource demand and their constant change of the UX, I gave up and went with Freecad and SolidEdge for 3D work.

The licensing model irritates me. It’s not that they want money that bothers me, it’s the unilateral approach to determine what a hobbyist would “need” and what features they think are only used by professionals. It feels condescending to me. Worse it comes from a company who has promoted their support of the hobbyist community as a gateway to their paid versions with continuous hawking of their commitment…then they change the definition of what that commitment means. It’d be more honest to go with a trial/demo version and a paid version.

I’ve never used Fusion 360. Since all we is 2D design, I went with Viacad 2D from Punch software, one time purchase. It does the job just fine. Plenty of tutorials on youtube to get up to speed. I don’t have issues making a DXF, send to Sheetcam then Mach3. It just works.

Agreed, after my first year of use as a hobbyist they told me I had to pay for it so I did $400 a year. Then I was talking to a tech support guy one day and he asked me what I used it for and I told him he said why are you paying for a license you are a hobbyist he referred me to a person and they changed my license now I don’t have to pay using it as a hobbyist. It’ll be interesting to see what happens in November when my license is up again. Betting there going to want to charge me again. Little do they know that I am going to be learning how to use other software by then getting really frustrated with all the updates and changes that don’t do me any good but just cause problems…

What kind of stuff do you primarily do with fusion?

Custom sometimes very detailed signs. Some complicated brackets and gussets. Some other stuff for Jeeps and side by sides

I don’t do many signs or anything like that that’s only for friends or family occasionally and I put it off as long as I can.

Everything I do is dimensional custom parts or reproduction parts and fusion excels in that so much to get what I need easily and I haven’t been able to find anything that compares but I’d love to find a 2d program that had all of fusions tools but I haven’t been able to find one that comes close.

For detailed signage, Affinity Designer might be a good option. $25 one time fee right now. Making brackets no matter how “complicated” can be done in most any simple 2D cad program.

I do custom fuel tanks & Fusion was my go-to because of the sheetmetal support. It takes a 3D design and unfolds it and adjusts the dimensions using the k-factor for the material the tank is going to be made out of. Then it’s a simple matter of folding it up and welding the appropriate seams and it comes out spit on.

I moved to Freecad and their sheetmetal support is similar so I haven’t skipped a beat. The Fusion licensing was okay (not great but okay) - just paid for a commercial license (the old hobbyist/small business up to $100K was a great deal). But all the jacking around was getting irritating. At retail the license was a decent % of profits depending on how many tanks I had time to make. Fortunately they had a half-price sale when they made the initial switch. Still don’t like what they’re doing so I just moved on instead of always being irritated ![]()

Just downloaded the trial of Affinity Designer. Looks interesting… Curious what you use after Affinity Designer to extrude, get cut paths, G-CODE, etc…

Export an SVG and import into Sheetcam for paths/gcode.

The sheet metal function actually works well but the only thing I use that for is to show a customer what the part is going to look like. Aside from that I just design everything in 2d and I know what extra material I need for bends depending on the material thickness so just easier in quicker in 2d.

Fusion works fine for me. No issues. What annoys me is that when the user model was reasonable I helped answer technical questions occasionally. I figured it was a fair tradeoff. Now that they jacked the price up they continue send me questions that I may be able to help with but I ignore them. Kinda ballsy I think. If you are going to charge a lot for your software you can provide the tech support yourself.

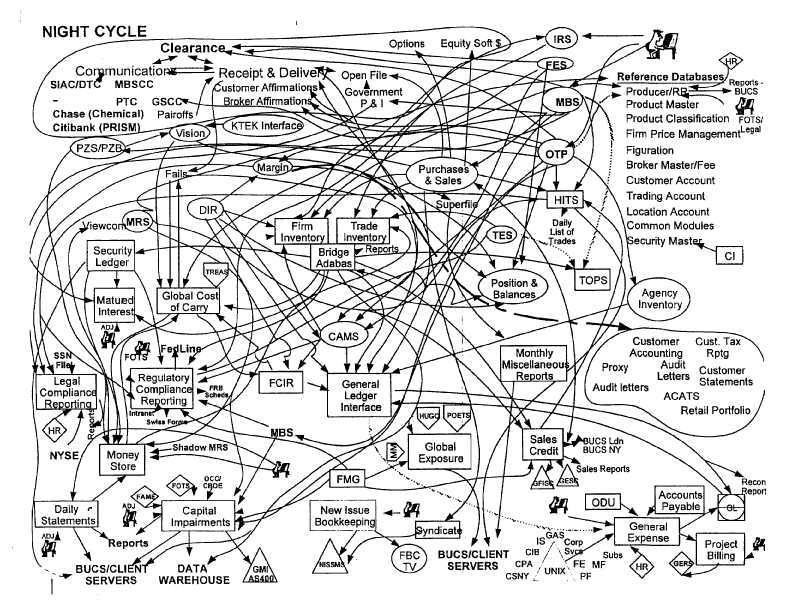

does anyone have a flowchart to navigate through Fusion 360

I have watched all the tutorials and managed to get one part done- I suffered brain lock trying to start again.

there must be a set of steps you guys all follow that don’t change to import a DXF, then run through the steps to generate code.

Open Fusion

Design should be selected on the left.

Click on the first Icon with the Green plus sign

Select the XY surface in the work area

There should be a Red and Green cross hair in the middle of the screen

On the right side top click on the insert drop down

Scroll down to DXF and select it

Click on the folder in the pop up

Your Files Folder should pop up

Go to where you have your DXF files stored, either in the computer or on a memory stick

Select it

Be sure it is orientated properly, you may have to use the cube in the top right corner to orient it

Click on finish sketch

Click on design and scroll down to manufacture

Next to manufacture click on the folder above setup

In the pop up select Operation and change to Cutting

Go down to Box Point and select a point on the bottom left of the drawing, the XY arrows should appear at the point selected. You may have to Zoom in to get the correct point

Now select the Yellow cube at the top of the pop up

Select the Stock side offset and change to .125" or to what ever amount of stock you want

Change Stock top to 0"

Click ok…

The Icons will change at the top

Select the cutter Icon. No need to select the drop down

A pop up will appear on the right side

Select the Tool select box

Select your tool from the library when it pops up

Now in the same pop up select your cutting feeds. DO NOT SELECT OK UNTIL THE LAST FIELD HAS BEEN FILLED IN

Now select the Icon next to the Tool at the top

Here you will select the Geometry that you want to cut

Now select the 4th Icon that looks like a channel

Leave tolerance alone

At side ways comp. you can select center for line cutting, Left comp, and right comp. Most will use left comp. Select comp type and select in computer. You can select preserve order and the computer will cut in the order that you selected. Do not select and the computer will cut the best as it sees it.

Now select the last Icon, Linking

If you have THC, DO NOT SELECT KEEP NOZZLE DOWN.

Select your lead in radius, select you sweep angle, select the lead in distance. You can use lead out or select it and turn it off.

The pierce clearance is set in the Post Process area

Select on the drawing where you want to start…

NOW SELECT OK…

Now at the top Select the G!/G2 Icon to Post Process the file and save…

I’ve been using Fusion a little over a year. It is a little slow starting up but when it is up and running seems to work fine for me. I just do basic 2D stuff with it . I run another table that has Hycad and sheetcam and it works also but I do prefer Fusion 360.

Well thanks fella’s seems that all of my problems lately are not just on me. Good thing i refer to this forum otherwise i would have had to learn solid works and im not sure that would be fun.

I’m glad you wrote about this because as a new user of Fusion 360, I was wondering is it Fusion or me. The natural tendency is to assume it is me, but I took a screenshot of some weird behavior and sent it to my son, who runs his whole show off Fusion 360. He confirmed it was not right. This makes it nearly impossible to learn when I have to fight with it all the time. I will give it a little more effort because I see how beneficial it has been for my son.