Got my sample Trafimet (made in Italy) torch in. Had the 2 trigger wires added so no internal wiring needed. Will plug directly into the Razorcut 45 and Vipercut30i. Now just gotta wait on my table

Gosh, that’s awesome! I had no idea a company made modular torches. Super cool!

I have an older PowerMax 30, that I so wish I could adapt a machine torch to it. I know that technically the PowerMax30 is not designed for machine cutting but I’m just a small time garage builder. Maybe one day I can move up in cutter models.

Thanks for the lead on Trafimet.

I had it made for me to sell and to use. Hit up my friend George he can adapt a torch to your machine

https://www.georgesplasmacuttershop.com/

Would love to get one of these on order what did it cost and what does it use for consumables?

PM or email me gamblegarage@gmail.com for a s45 straight torch.

I have been burning with the machine torch a couple days now and I like. I currently have the torch mounted in the Langmuir Systems torch mount however think I will be adding some additional tapped holes to the long aluminium tube and reworking a mount. Maybe think about adding a servo that raises the torch when it stops firing drops it when it fires but that will take a touch more thought.

Email sent. Thanks!!!

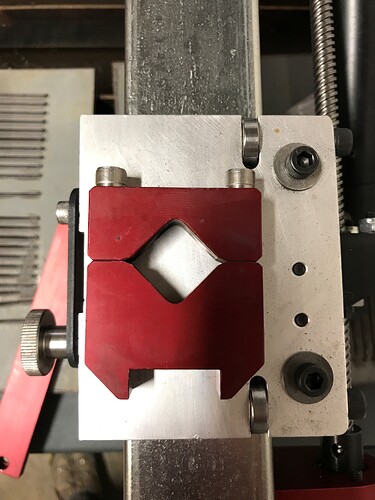

I’ve been running the s45 machine torch since day one I flipped and used part of the old ls mount and added an extra mounting hole to attach the new machine torch clamp block and lengthened thumb

screwDid you make the mount? I have been looking online at a couple.

I had someone machine a block of aluminum to accept the torch body may go with a magnetic break away later on so if I have a tip up it will break away rather than binding up and shifting material

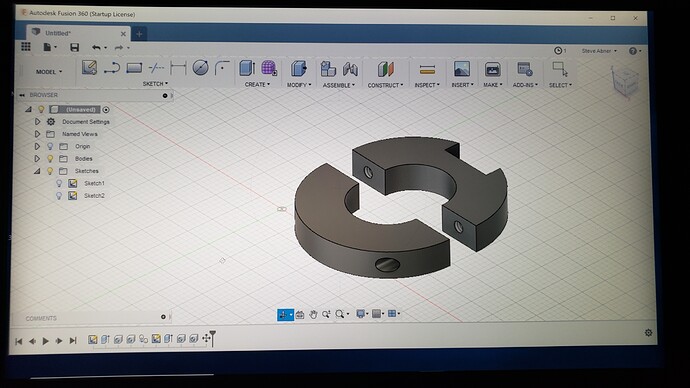

Anyone with a mill interested in making a couple of these ![]()

How much are you looking to spend?

I can maybe tackle this. I have a cnc mill that I’m learning how to use. probably take me some time so I don’t break any more end mills but it gives me something to practice on

I have been in contact with someone already so we shall see how things go.

blakebahruth’s mount is pretty thick I was thinking two thinner mounts.

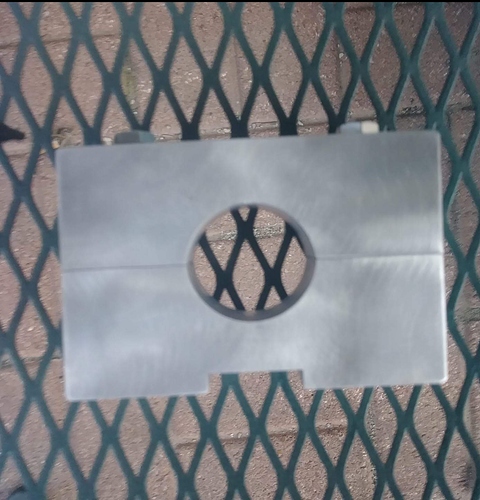

So this is what I was thing with the Langmuir mount as a example.

The picture shows the Langmuir mount. I would like to stay with something like this but with a round 35mm hole (1.378”). Width wise as compact as possible. The Langmuir part has a bolt spacing of roughly 1.55” so that needs to be opened up thinking 2.0” bolt center.

The Langmuir part

• The bolt centers for the cap are roughly 1.55” ¼”-20 bolts

• The mounting bolt in the center of the mounting notch is 10-24

• The notch width looks to be 0.987 using a caliper ) using a good micrometer on the upright the notch fits I had 0.98575”

• The notch depth looks like 0.325” (I would like to shallow that up a bit as I would like to use two mounts and need clearance to slide the vertical mount.

Desired Part to be similar x2 as I would like two

• The bore for the torch 1.378” minus a touch on the split cap

• 2” bolt spacing ¼”-20

• Mounting slot 0.225” to 0.240” deep 0.987” to 0.988” wide with a mounting hole in the center of the slot tapped 10-24

Pretty handy to have the Fusion software for other work, provides for a nice visual.

Here’s the mount for Rich Horn’s machine torch. I’m willing to bet gamblegarage and his cnc or the LS guys could refine it and crank some out for you guys running a permanent torch.

Holly fab shop batman! I am extremely jealous of all your toys! I work in an industrial sheet metal shop, and we dont even have equipment that Nice! Well done sir. Hopefully someday my shop will look like yours.

Hey, thanks Jeff! Been a few years of buying cheap, fix and spit polish to sell up to what I really want.

That looks great!!! Nice job