@Domo Welcome.

A smaller diameter will increase the Reynolds number ( turbulence ) in the pipe which is great for heat transfer and bad for entrainment of condensed moisture. This means that some of the liquid moisture can be carried along to the next device. a Larger pipe will also lower your velocity which subjects the air to the heat transfer of the heat exchanger for a longer time while minimizing entrainment.

Personally I have a different opinion on this .

Dessicant is a must if you hope too achieve the correct pressure dew point in your air .

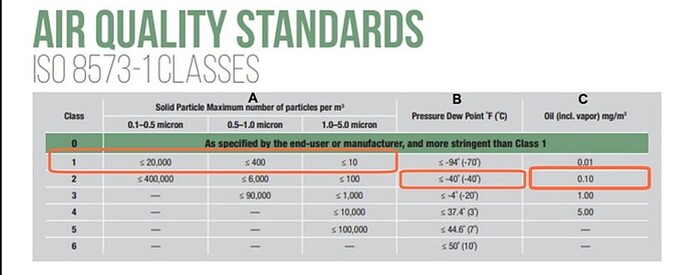

This is the standard you should be aiming for.

ISO 8573-1

Class 1.2.2

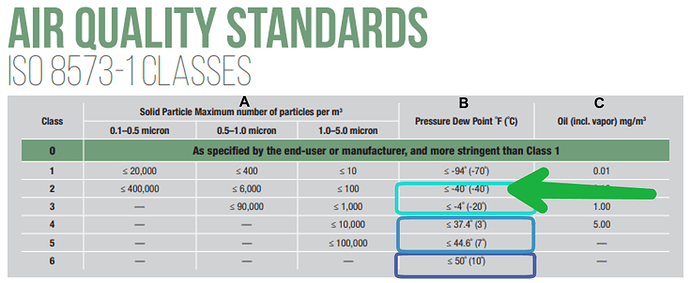

Column b deals with water vapor.

The dark blue is where a passive or active ambient air cooler will get you to.

The blue color is where a refrigerated air dryer will get you to.

And the light blue is where a desiccant cell will get you to.

Sketchup is…was awesome !! I used Sketchup from 2008 to 2020 then i moved to Fusion 360. You could still use Sketchup with SheetCAM which maybe a good combo.

Where are you reading this?

A rough rule of thumb for recommended amount of desiccant would be approximately 0.2 to 0.3 pounds per CFM of compressed air. but this will vary depending on temperature and RH of the inlet air to the desiccant cell.