Well at the moment I’m pretty happy with the cut after I changed the consumables. Just the holes were a little out of whack. I’m at 80 ipm and 30 amps. I might try to slow it down 50% or so on small holes. I cut some 5/16 with the actual factory consumables at 45 amp and the outside cuts were nice, but the 1/2" holes were tapered. I’m hoping slowing down the ipm in holes will help that.

There will be some amount of taper it’s just the way plasma works but you should be able to get it to tolerable levels. Conventional wisdom is about 60% of speed on holes or tight inside corners.

I’ll give it a try thanks for the help

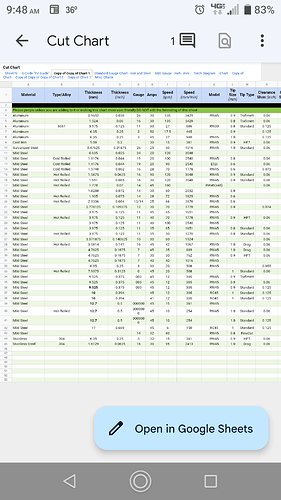

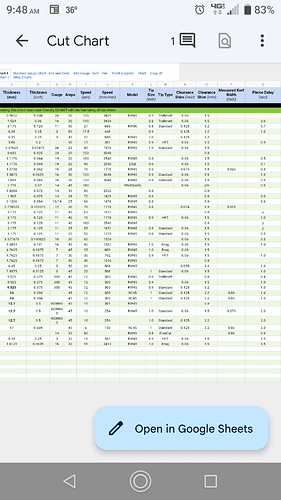

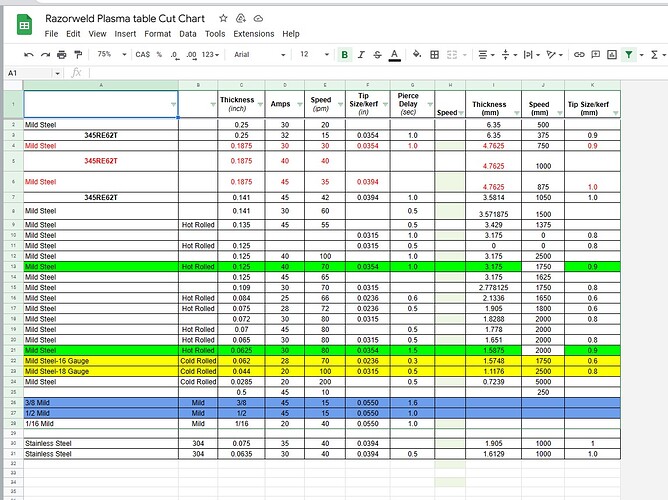

That chart seems a little ambitious to be for a Razorweld machine. Over 600 IPM on 14ga. steel? Even the optimum speed of 220ish is a bit too fast for a Razorweld.

Does seem high, but the optimum rate looks more realistic. I can’t vouch for the chart it came from the forum but it seems better than nothing or at least a place to start.

must be a misprint they have 16ga at 178ipm above it as 10ga at 151ipm below it .

My guess is it was suppose to be 164 ipm? instead of 640 ipm

all so 221 ipm is a misprint if you look at the numbers above and below it . maybe it was suppose to be 102?

even the mm of 14ga has errors

I have a RW and cut 14 ga at 120 at 45 amps. I might be able to go faster but have never tried as my cuts are good at that speed. Maybe next time I will try 140-150. 220 seems way to fast

The numbers above the 14ga line are for 25 amps, whereas the numbers for 14ga and below are at 40 amps on that chart.

yes i see that now.

check out the stainless number for 14 ga 221 ipm / 144 ipm at 40 amps

i still think the 14 ga mild is a misprint

Probably so, but the whole chart does not seem to be for a Razorweld machine. I don’t know of any actual cut charts put out by Razorweld or Jasic.