Ok cool I will watch those forsure. I can run and design stuff on F360 on my computer. my problem is that i havent been around long enough and that I am to wet behind the ears on this. I also am unfortunately an A-B person and dont like diviations but its turning out all there are deviations LOL. I appreciate all the help I can get from this forum and others. It totally operator error %100

Gotcha totally man and I appreciate every reply and you bringing that to the table. I am like %100 new at this and am getting a little frustrated LOL. You definately have a lot of knowledge in this. I am just a peanut brain and it is getting fried LOL

Hang in there you will makes sparks fly soon!!! Kinda odd you computer can handle f360 but not compatible with sheetcam.

It is straight A to B once you get used to it. ![]()

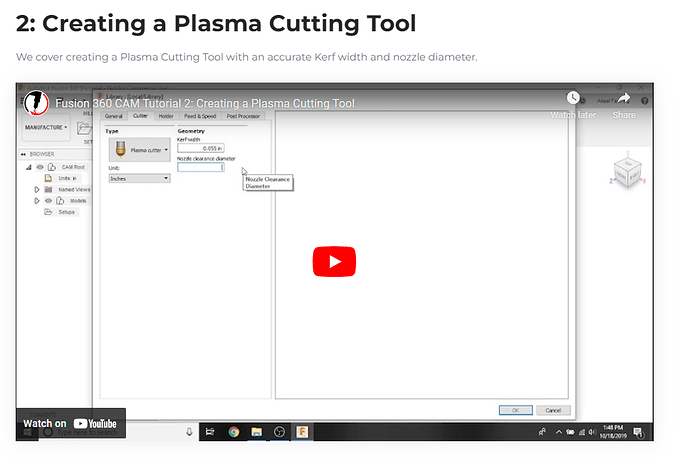

I understand. The part that really trips people up in Fusion 360 and SheetCAM the first time is that you do have to set some things up such as “tools” and the “post processor” file.

The post processor file is what Fusion 360 and SheetCAM need to make the g-code. The g-code from SheetCAM will be a xxx.tap file and from Fusion 360 will be xxx.nc. They are both simple g-code files that FireControl understands. It is basic instructions for moving the gantry and torch and turning torch on/off.

So it is good to have the post processor file loaded somewhere on your computer (where you can find it) and understand how to enter some simple details of the tool (torch cutting specifics for a specific metal type and thickness).

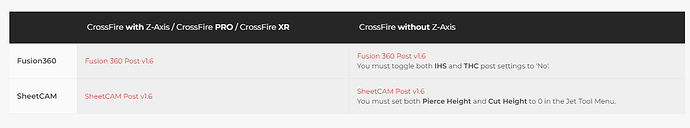

The post processor file is downloaded from here:

https://www.langmuirsystems.com/downloads

For the tool entry in Fusion, you would want to watch this video:

https://www.langmuirsystems.com/software/fusion

Now you are ready to take your file into manufacturing.

I’m newish as well and the videos Jim has linked above are great to watch each one from start to finish and follow along and it will show you how to create a simple bottle opener and turn it into G-code.

There is some settings in fusion that need to be setup or you will run into issue but the videos walk you through very well.

Right thats what I am hearing

Thank you for that explanation.

it would be great to have and 3D category on the drop down filter for guys who have MR-1. I don’t think people would want to run somebody else G-Code on their CNC since it’s tool based, but sharing solid models is fun and useful.

Totally agree.

I know there are many people that look at the plasma cutting process as a 2D event but I often point out that many of our projects end up being used for a 3D object.

Example one:

This was my fourth and best rocket stove as it was the most successful cutting and building because of the 3D environment offered by Fusion 360 (and a little help from the Tin man).

Example two:

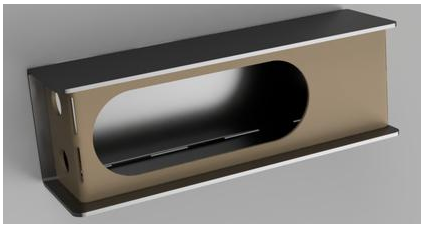

I wanted better lights for backing with my trailer. 3D boxes would be the answer:

Unless you are making flat signs or support gussets/brackets you are probably interacting with a 3D object. So whether it is solid or sheet metal, the 3D world is where the fun begins.

Edit: Sorry Richard. Now when I re-read this topic and your ask…I may have strayed a bit off the path you were going.

I totally agree. I design machines for a living. Everything I do is a 3D assembly first than I cut the pieces. I have a crossfire pro and MR-1. I wasn’t sure if other people use their crossfire pro like you and i do but I for sure know people are cutting 3D objects on their MR-1.

I think it’s time to have a 3D category. ![]()

Agreed! Don’t forget all the 3D printers it seems everyone around here has…

But only for Windows based PC’s…when is the Mac folks getting this?

I’m learning as I go but a couple of days ago I downloaded a cut ready file from Fireshare and when I went to cut it, I got an error. The message said “Line 10 G4 P15

Gcode words consist of letter and a value. Letter was not found.”

This morning I tried downloading a very simple file and got the same error but it referenced line 54 instead of 10.

Can someone help me figure out what that means?

Thanks, Mearl

Can you copy and paste the entire code here?

G4 P15 would be your pierce delay. That would be 15 seconds. are attempting to use millisecond?

Is there a possibility you downloaded a cut ready file for mach 3?

I think you’re right. When I was downloading the file I may have fat fingered the pierce delay. Unfortunately, I deleted the file from my computer because I was just going to try it again but now I can’t find it in Fireshare. I’ll keep looking and if I find it, I’ll try to reload it correctly.

Give a update when you try again. What was the file you tried?

It was a hat and boot with cowgirl and said Long live cowgirls. I couldn’t find it using the search tool but I’ll keep looking.

Possibly use the filters option to narrow down your search. If it does work then. Share the link and we will figure it out.

I tend to stay away from cut ready stuff I do understand being new to the game. I always look at cut ready is potential for a sperate issue. I try to get the dxf or SVG

Here is lots of images in the theme of “Cowgirls.” Perhaps you could find something that works here:

Just put “Long live cowgirls” in their search bar

Here is one on Etsy:

https://www.etsy.com/search?q=long+live+cowgirls+laser&ref=pagination&page=9

Thanks, I’ll find something nice, I’m sure. I went through Fireshare one page at a time and never did find the file I was trying to use.