What’s more expensive, down time or arc on time? What makes money, down time or arc on time?

The way I look at it, is you know already that you’re making 4,000 of said parts a year, so this isn’t a hobby. Knowing that you’re selling said parts, means you know there’s revenue coming in and there’s a profit being made. Assuming $1 from every part goes towards the machine, in one year, at that rate, the machine pays for itself. Say $2/part goes towards the machine, that’s a 6 month pay off. At $5/part going towards machine overhead, pays the machine off in 800 parts.

I use my machine to make me and my business money, I don’t want to worry about machine down time. I turn my 45xp on and every single time it does what it’s supposed to and has since the day I bought it, both on and off the table, to say mine gets a workout would be an understatement.

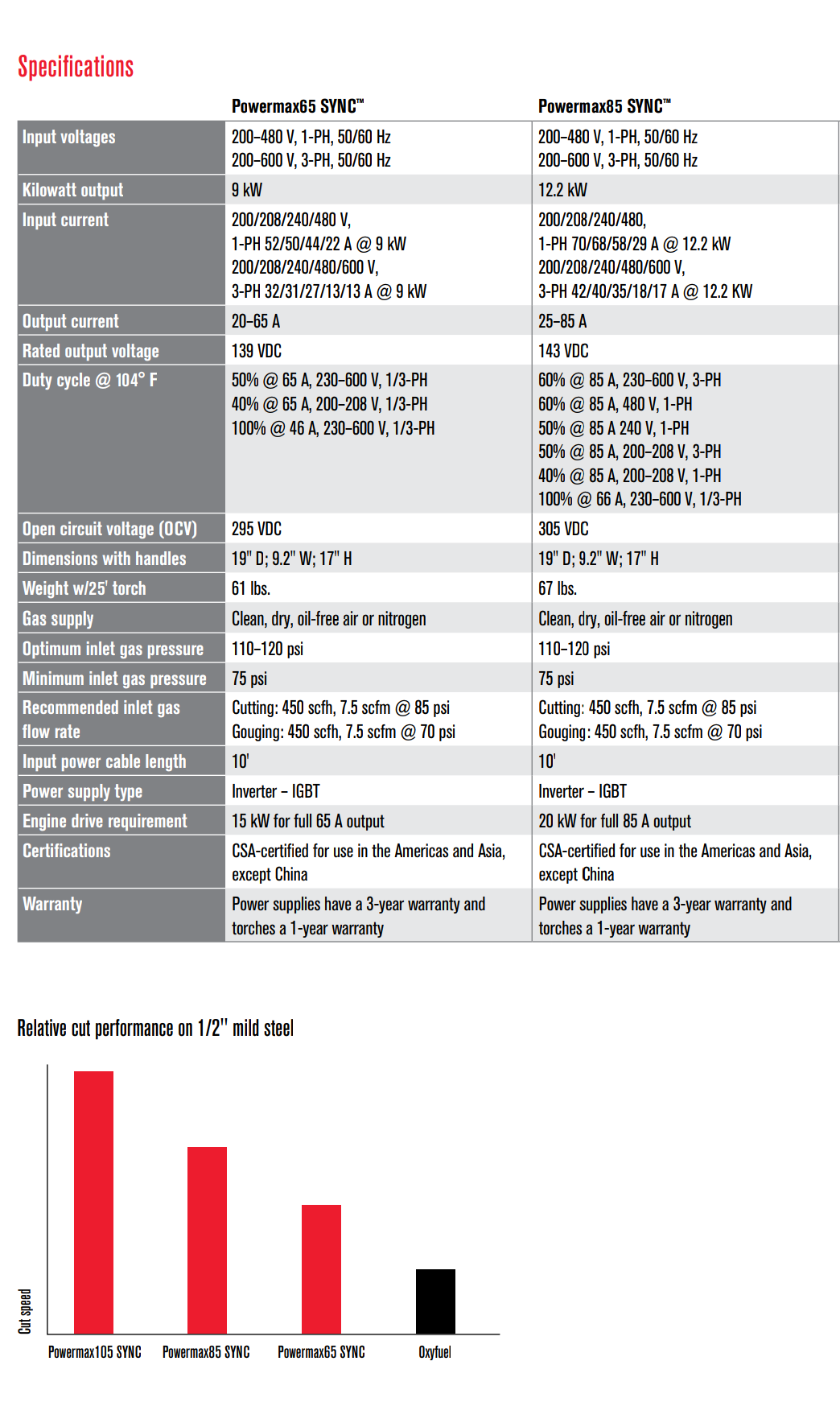

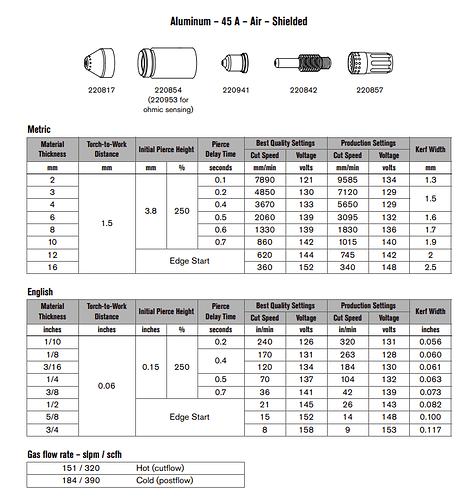

Plus Hypertherm machines are the most efficient machines on the market, along with having the most superior nozzle/consumables design in the industry or air plasma. That’s another thing to look at, consumable life. Say you buy a $2,000 plasma that hogs through consumables, you’ll surpass the savings with having to replace consumables more often, ESPECIALLY if you’re piercing 1/2” all the time, even with a wiggle start. Not all cheap tools are bad and the cheaper plasmas will likely work fine, but when they shit the bed in the middle of a job, where a good machine would just keep chugging, your profit making comes to a halt.

Just spend the money on the Hypertherm and go make money and thank me later. You’ll learn really quickly, these machines have an incredible return in investment, keep it busy and it will pay for itself many many times over, mine sure has. The table itself is super basic, the real magic happens in the plasma cutter.