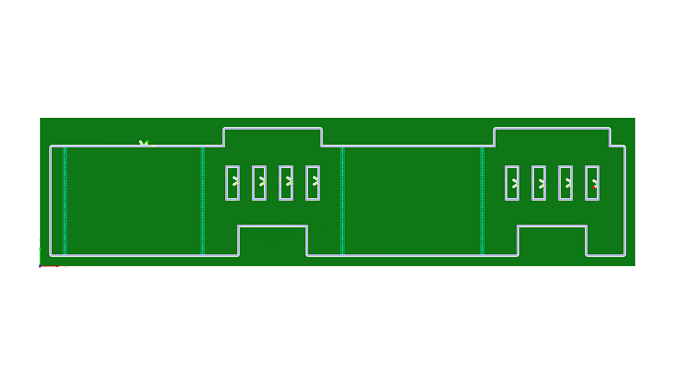

Okay so I created the G code but something isn’t right. It’s added the two loops (shown as orange) as cuts which shouldn’t be there.

I see that too.

That must be some conflict with the keep nozzle down setting and the post processor.

I never post process anything without torch height control and I don’t use the keep nozzle down setting so I’ll have to do a little bit of investigating to see how this happened.

I did notice that you had the keep nozzle down setting active in your f3d file so I did leave those settings alone.

Yes I read (or saw a YouTube) that if you aren’t using THC, to use keep nozzle down with the distance being the size of your tables maximum cut.

I use Keep Nozzle Down on everything I cut which is usually sheet metal. This however is my first time using sheet metal rules.

Why? What’s the advantage of that?

i removed keep nozzle down and it removed the odd loops.

chimney cap lf pete17 v5 without keep nozzle down.f3d (430.6 KB)

golden wo keep nozzle down.nc (3.9 KB)

this may show up better for you.

Not sure. I’m totally new to this and spent many hours researching and watching youtube tutorials. It would’ve been either Lars Christensen or Arnold Rowntree that said to do that if not using THC.

I’ll give it a try…thanks.

I think this is a case of having THC (torch height control) confused with the Z axis and IHS(initial height sensing)

The keep nozzle down function eliminates all z axis movement in the gcode. It is used for machines without a z axis and without IHS. I am assuming you have the crossfire model without the Z axis upgrade? That being the case you are correctly selecting the keep nozzle down function. Otherwise you would get a fault when fire control reads the z axis movement without a z axis to command.

If you do have a z axis and IHS there is no benefit to selecting the keep nozzle down function.

I have no idea why it seems to be making those rapid movements into cut loops… but I am sure @TinWhisperer will get you squared away.

I am still try to figure it out myself…

golden with zero retract.nc (3.9 KB)

here is another with zero retract.

I am not to familar with the keep nozzle down feature and I keep ending up with those loops if I use it ?

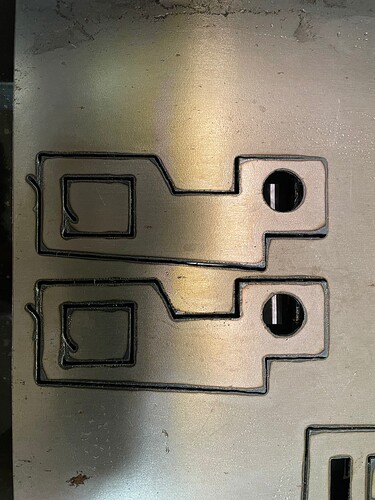

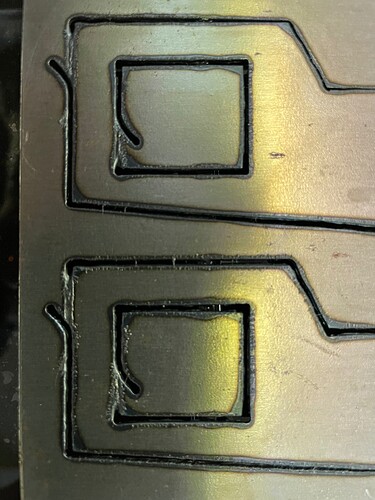

I had to redo the G code to deselect IHC and THC and just did a cut w/o the keep nozzle down selected and it did work but still very messy results. Some of the small rectangles didn’t cut all the way through.

1/16" torch height set with supplied spacer

250ipm, 27 amps with 65 -70 psi.

Front

Back

Yes you are correct. I do not have the Torch Height Control upgrade.

Very puzzling.

And you have good consumables and dry air…

It might just be the dross making an optical illusion but it doesn’t look like it’s cutting very square.

Do you have a MAG brake, how are you going to fold that up?

Consumables are in excellent shape and air is super dry.

I have a box brake to fold it. It’s tricky but I did it a few months back.

While I’m on that subject, I did a test cut of this back in March and it turned out great. Almost no dross and clean sharp cuts. Sadly due to a computer issue all information on that file was lost.

that cold rolled sure look likes stainless .

even now some inside holes cut different than others with the same programming which make me think it could be a plasma issue.

It’s definitely not stainless. I just tried again with new consumables, just in case and l got the same results.

I might try a different file.

Maybe some straight line speed tests are in order to get your inches per minute dialed in.

I just tried a different file as a test. It appears that the torch is not cutting all the way through at the very beginning and end of each part of the file. That can’t be the plasma machine could it as it happening every time no matter what the file.

You have cut this file in the pass with no issues?

what is your pierce delay?

I did cut this months ago with great success but the file was lost when I had major computer issues. The one you’ve been working on is a redo of that file, the only different being, that this one uses sheet metal rules.

The test I just sent pics of is a completely new file created this afternoon.

Pierce delay is set at 0.5.