I am trying to make a cut using 14 gauge steel on my crossfire, using a razorweld 45, and I need help with tuning my settings for Sheetcam I’m also not sure how to distance the nozzle from the work piece properly, as I don’t have the torch height control

So we understand how to help you, a powered Z axis is different from a Torch Height Controller. You can have a powered Z axis without a Torch Height Controller. I’ll assume, since you posted in the Crossfire category, that you have neither.

With a standard Crossfire, you set the Torch height with the provided shims. For cutting 14ga. steel, you would use the .060" or 1/16" shim between the Torch tip and the metal.

In your Sheetcam tool, you will set the pierce height and cut height to zero. If you don’t do this, you will get an IHS fail error.

I usually cut 14ga at 35 amps and 140 inches per minute. I use a .4 second pierce delay, but you should probably start with at least a .5 second delay.

Thanks, I will try to adjust my settings towards what you have and see how it works

We currently use a RazorCut 45. For 14 ga (.0747") we use 145 ipm and a 0.75s pierce delay at 45 A. I agree that the .060"/1/16" shim is correct for this application. (If you had a powered Z axis, I’d raise the pierce height to .150", but this is not a show stopper.)

Good luck!

I also have a sheet of 11 gauge that I need help with

45 amps and around 90 to 100 inches per minute with at least a .5 second delay. Same spacer as the 14 ga.

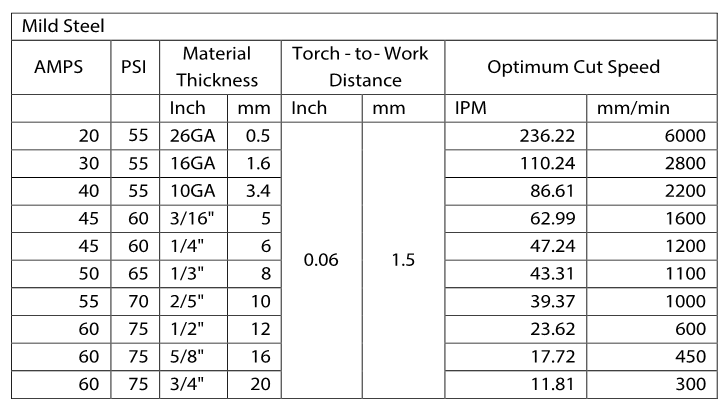

I don’t have a RW but this is a snip from the PW CUT60 Chart. Both machines have a similar output voltage at 45 amps so it should get you close. For material thickness not shown you can interpolate the value from the chart. I played around with it a bit and was getting values close to what @ds690 shared. You will need to do some testing to verify… The chart (or values you get here on the forum) just gets you a starting point. There are test coupons on fireshare you can use to experiment with different values. I think there is also a thread on here with a RW cut chart that people have shared. I wouldn’t cut anything without doing some testing on your own to verify what works best for you.