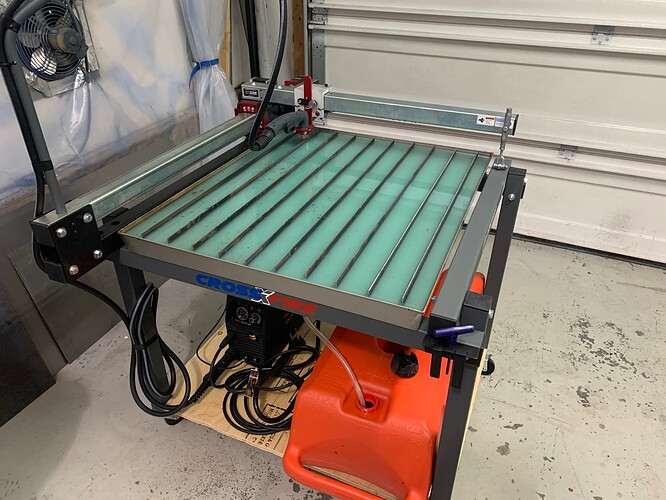

I have the gen 2 xl table and have modded my table expensively with some worthwhile changes. Some can be used on any table.

- Bottom shelf

- Casters (I move my table around my shop)

- Hand torch splash shield (version 2 on fireshare)

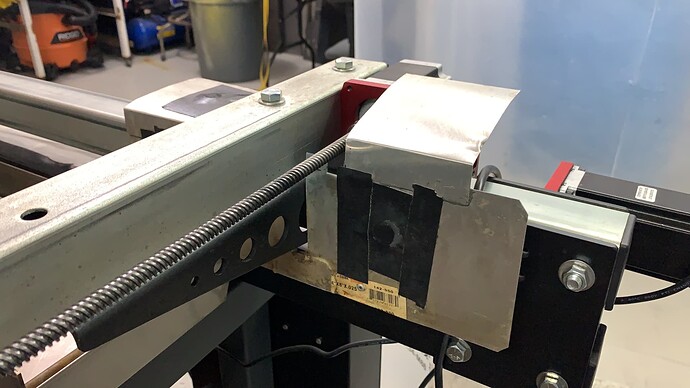

- Splash shield made from 22ga aluminum that completely covers the gantry bearing assembly (by far the most worthwhile mod as it keeps the crap off the bearings but also keeps the majority of dirty water off the y axis rail. Held in place by two neodymium magnets for easy removal and cleaning. Cover the magnets with gorilla tape so metal dust attracted to the magnets can simply be wiped away)

- Poly curtains all the way around the table (keeps crap off my bottom shelf and keeps the control box free off dust and splashes, don’t worry, they are not going to catch fire)

- Pump and filter (12v). Useful for transferring fluid from table to fluid storage reservoir residing on bottom shelf, I use this to save cutting fluid if I’m going to be away from the table for a week or more)

- Fluid storage reservoir on bottom shelf (10gal)

- Gorilla tape dams all along the perimeter of the table significantly reduces the volume of fluid splashed over the side off the table while cutting. ( fold gorilla tape lengthwise and tape into place the full length of each side. Tape in place so it extends 1” above the water table edge. When metal is layed on top the flap of tape created simply folds down below the level of the slats and directs water back into the water table, creating a dam or seal, works well)

- Buy a small, cheapo wet/dry vac and dedicate it for water table clean outs. Nothing works quicker

- Get a machine torch. The hand torch is adequate, but the machine torch makes everything easier and cable is out of the way.

- Get thc, thank me later.

- If using crossfire table, install bearing arm to support the free end of the gantry arm and the bearing can track along the table rail. ( this works so well if you don’t have thc, keeps dead even torch height across all parts of the table, used it for a year before I got the thc, but I still use it so the thc doesn’t need to do much work. Made mine so it swings up and out of the way when putting sheets larger than my cutting surface on the table.)

- Install a 10-12” barn fan in your shop wall at table height next to where the table will operate, and allow replacement air to enter shop, as these barn fans are powerful and you need fresh airflow.

- Create an enclosed space with poly within which your table will operate. (I strung high tension aircraft cable across two directions above the table, and created a poly room that prevents dust and vapors from contaminating the rest of my shop, poly “Walls” can be collapsed against the wall of my shop in 1 minute which removes my “room” when I want to make room in my confined shop for other projects.). I use this collapsible room for cutting, grinding, powdercoating, and painting.

These mods are mostly aimed at keeping table clean, and making table easier to clean, which aids in reducing maintenance and failures. A clean table is a happy table I’ve found.