Just a basic question. Between fusion and cut control does it have the ability to machine multiple parts at a time. Not different operations but say you have the ability to fixture for example 6 parts at a time. Can you machine the same operation on all 6?

Don’t know yet? No one has one yet. It might be a question to ask Langmuir. I hope so but, I don’t anticipate it. First machine are due for shipping at the months end…

I was going to ask them on the mr1 owners Facebook page but im in Facebook jail again.

Sorry to hear that… Me too.

I would say its very likely that you’d be able to have multiple work offsets. And if in the event that is not the case - you can also do the multiple machine operations in your CAM. More than one way to skin a cat (Old folk saying, please dont yell at me!)

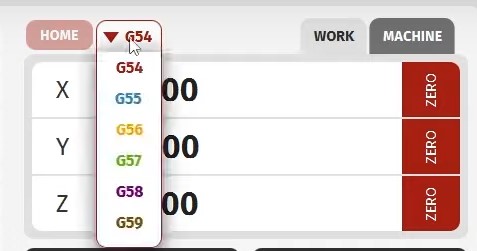

Looks like CutControl supports multiple offsets. And, as you say, if you can program it CAM and fixture the stock accordingly, the machine is just going to execute the code.

I can’t imagine it wouldn’t be able to. You can run the same piece on plasma although I’ve not yet played with that.

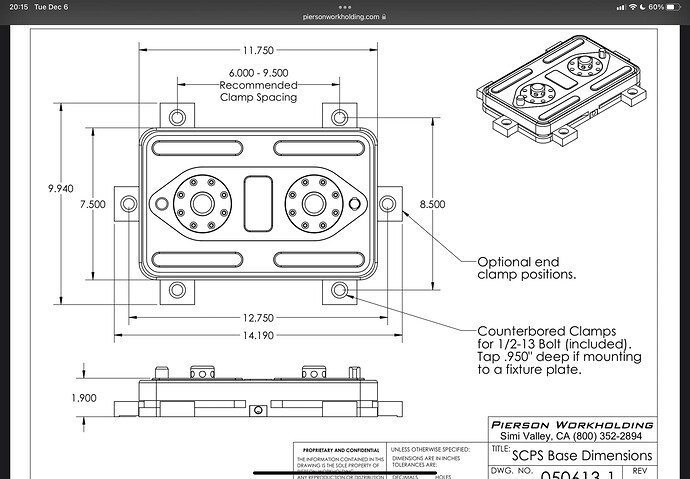

With that being said do you think a Pearson pro pallet system would work on the MR1

Can a pro pallet work, sure. But with limited Z axis travel, you would have to have very short tools. If I am recalling correctly, the pro pallet will take 2.5-3" of Z travel away. But , I have thought about doing that also to run multiple parts at a time.

Yeah the extra 3 inches has me a little worried if it will be a viable solution or not. Depends on what someone might be making I guess. The extra 2 inches you get by adjusting the ZX and spindle doesnt really do anything for larger parts. You will always be limited by the spindle mount on the x-axis gantry. It looks like it protrudes an inch or two below the X axis gantry which can never be changed.

Agreed, the gantry will always be a limiting factor.

I wasn’t familiar with the pro pallet but knew Pierson was $$.

Very nice. Didn’t see any height dimensions though.

The pallet starts off at 1.5 inches I think.

With this screenshot it means that you can guaranteed run at least x6 operations at a time. Maybe more in the future is they add support for G54.1, .2, etc…

I plan on running the SMW mod-vice system with the Dual-station. You could fit x3 SMW pallets on the mill (with 2 inches on one SMW pallet handing off the side). You could fit 4 small parts on one pallet that could be a total of 12 parts total. Or two medium sized parts per pallet would be 6 parts total.

Given the size of the machine and the probe I hope they allow for more than just 6 work offsets.