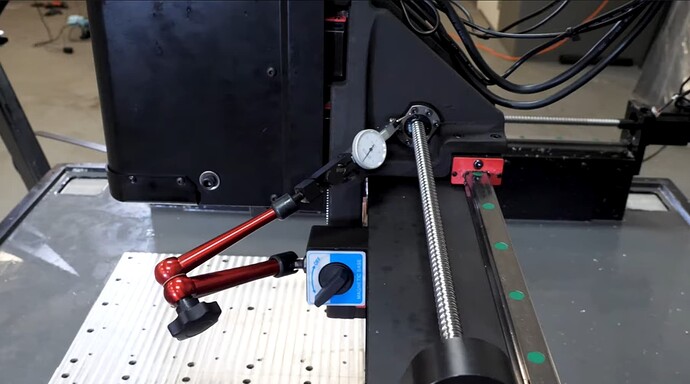

Hello, I am just finishing the assembly of my MR1 mill and checking the ball Nut lash as shown in the assembly videos. On the 2 y axis I am getting 1 thousandths or an inch of lash and on the x axis I am getting almost 2 thousandths. In the video he is saying 1/10-3/10 of a thousandths is within specs. As far as I am aware, these ball Nuts are not adjustable so I am worried that maybe I got some out of spec ball nuts?

thank you for any help provided,

Ernst

Welcome to the Forum! I’m moving your post to tha MR-1 category so it gets more eyes.

Also copying @langmuir-cameron who handles MR support.

LOL, This thread title made me think: “Mr. Ball, has Nut Lash” which we generally don’t treat in this forum ![]()

Hi @oracleartist welcome to the MR-1 group!

Just to make sure I’m following, In the videos they are checking the lash of both the entire ball screw itself and then just the lash in the ball nuts. The lash adjustment in the ball screw is where they say 1 to 3 tenths. For the ball nuts there’s a note that pops up on the video that says Max allowable is .001". However, your X axis nut does still sound like it’s exceeding that.

A couple of quick questions:

Are you measuring the lash in the nuts with the DTI attached to the gantry and the needle resting directly on the x axis ball nut flange as shown in the video?

What is your lash in the ball screw? If you run the nuts down on the ball screws to the zero lash point, does that change the measured amount of lash you are seeing in the ball nuts? Excessive lash in the ball screws would compound the error in the measurement at the nut.

Yes, it was measured like that and the ball screw lash is 1/10 of a thousandth. The ball nut lash is a hair over 2 thousandths.

Ernst

Okay, agree with your findings then, definitely sounds excessive. I would get a ticket started with Langmuir.

In the meantime I would also disconnect the ball nut from the carriage and spin it back away from the casting and measure it directly on the ball nut too. With that much lash it should look and feel loose.

They will probably send you an entire new ball screw and ball nut combo. At least the X axis ball screw assembly is easier to replace than the Y’s!

Yes, when I remove the ball nut from the casting and rock the ball nut on the ball screw I can feel a bit of motion and hear a knocking sound.