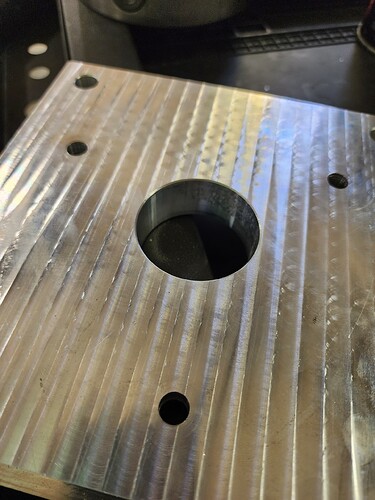

Made this this morning. This is so I could bolt down

a 6 inch lathe chuck to base plate for round parts.

I ordered a low profile chuck to keep the height down.

Still in development stages…

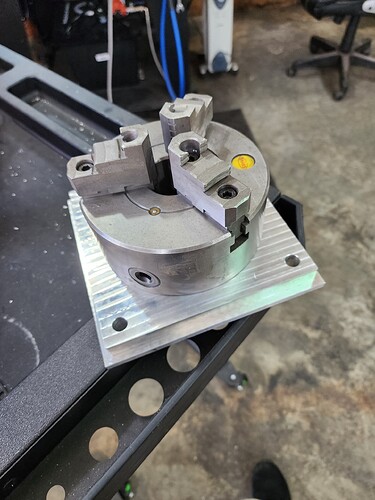

Man, that’s not very “low-profile” lol But handy to have!

I know. The low profile chuck will give a inch or so. That chuck was a test fit.

Still working on this. Haha

OOohh…gotcha. I thought that was the low profile. An inch will help.

Where did you order the low pro chuck? Am thinking of doing the same. I have a 5 inch chuck in mine now with some toe clamps, but they make me nervous.

Still shopping for one. I’m leaning towards a 6" 4 jaw with independent adjustment.

They are almost 2 inches lower in height.

Atlas has a real nice 3 jaw but its almost a thousand dollars. I let you know. They all will fit the three bolt back plate I made.

In the mean time I’ll use my standard 3 jaw that was in the picture. Its not to bad if you take out the langmuir vises and bolt it down to the machine plate.

Yeah, I figured they wouldn’t be cheap. I’m making an oil cap for a mg midget twin cam and my clearance height with my 3 jaw is real close for comfort, even with it clamped straight to the base plate. Clearance is clearance though

4 jaw chuck is definitely the way to go for a mill!

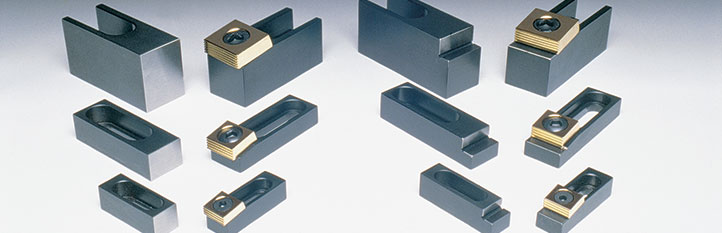

If you’re going 4-jaw you might consider some of the products from Mitee Bite

You could choose your favorite spot on the base plate (or use the adapter plate you already machined) and just set up a couple of bolt patterns to use their adjustable fixture clamps directly on the plate. The bolts that secure the clamp portions are eccentric so custom soft jaws can be machined easily if you need to fit a custom shape.

They look sweet… Great Idea.

Cool project and useful!

I second the use of mitee bite products. Small but very effective clamping. I personally have warped a 1/2 inch aluminum plate with them.

How much do these cost? I did a quick check and they were $70 a piece? If so they can turn to be quite costly for what they are.

I havent looked recently but I use these for work regularly and I think they come in packs. Make sure that price isnt for a pack of 10 or something

If you have more time than money you can knock out your own mighty bite style clamps.

And make hardened jaws for them.

I’ve also made low profile “mitee bites” fore use on a fixture plate. Some brass hex and turn an eccentric bolt on the lathe and done mostly. Much cheaper and once your set up you can bang a bunch out. Not sure how mine compare in strength to the actual product, but I’ve never had an issue with them. Side note: I agree that 4 jaw is the way to go on the mill. Small 3 jaws dont have the holding power of a 4.

This is what I ordered. We will see if it works.

If not I’ll use it on my South Bend Heavy 10

Lathe.

Pratt Burnerd/Atlas 4-Jaw Independent Iron Body Chucks

Series 441 Medium-Duty Value Line, Sizes 5" thru 32"

Why bother with an independent on a chuck below a mill? Youll be center the spindle to the work anyway.

A 3 jaw chuck has a large ring gear in the back to make the jaws work.

The 4 jaw independent chuck is almost a 1.5

Thinner. That will give me more z travel space. Well that’s my theory anyway.

Also, you will get better clamping force and stability of the part with a 4 jaw over a 3 jaw