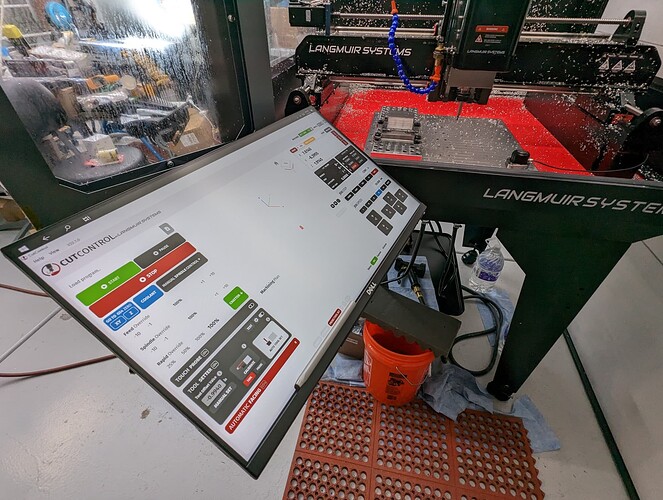

I decided not to purchase the monitor/pc/mount from Langmuir as it felt like the fixed configuration was going to enlarge the permanent foot print of the machine more than I wanted. It was also possible to get a larger (~24") touchscreen and more ram/storage within the same cost envelope. My desktop currently has a 6x Ergotron LX monitor arms and I’ve been very happy with them. I’ve also used Ergoton LX series for mounting a small TV.

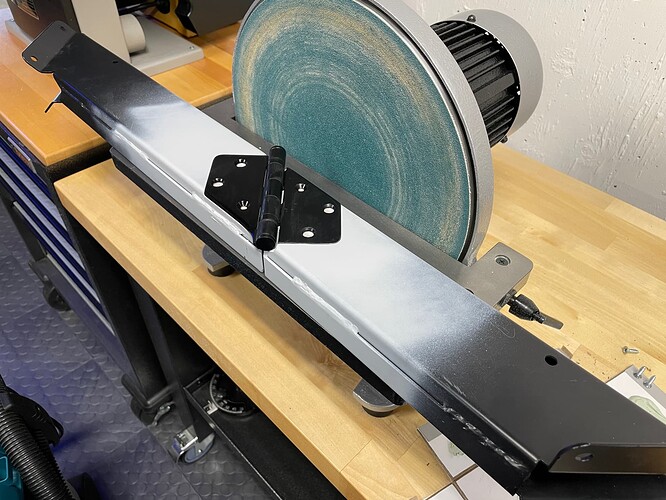

After reading reviews online, it was suggested that the AmazonBasic monitor arms were actually manufactured by Ergotron. This was tempting as the Amz model is less than half the price of the LX. I was hoping that the “silver” model was simply cast aluminum that had been unpolished but it is actually painted. However, I can confirm that the AmazonBasics arms are indeed Ergotron LX parts but with lower fit and finish.

I drilled one hole in the legs to be able to mount the arm base with 5/8" 1/4-20" socket head screws.

The arm on the left is amazonbasics, the arm on the right is Ergotron LX.

Note that Ergontron does have other models with significantly more “lift” height that would allow for different mounting positions but the price would be 3x that of the amazonbasics model.

BOM

- Dell P2418HT 23.8" Touch Monitor - 1920X1080 LED-LIT

- Amazon Basics Wall Mount Computer Monitor and TV Stand - Lift Engine Arm Mount, Aluminum – Silver

- HumanCentric Mounting Bracket Compatible with Intel NUC VESA Monitor Arm Extension Plate Compatible with The NUC Mini PC Computer

- Intel NUC 11,NUC11ATKC4 Atlas Canyon Home and Business Barebone Desktop Mini PC (Intel Celeron N5105 4-Core, 4-Thread, 15W,Intel UHD Graphics, 450-800

- Crucial RAM 16GB DDR4 3200MHz CL22 (or 2933MHz or 2666MHz) Laptop Memory CT16G4SFRA32A

- Monoprice Select Series USB 3.0 A to B Cable 1.5ft Compatible with Brother, HP, Canon, Lexmark, Epson, Dell, Xerox, Samsung and More!, Black (113746)

- StarTech.com 1ft (30cm) DisplayPort 1.2 Cable - 4K x 2K Ultra HD VESA Certified DisplayPort Cable - Short DP to DP Cable for Monitor - Slim DP Video/Display Cord - Latching DP Connectors (DISPLPORT1L)

- Adonit Mark (Silver) Aluminum Stylus Pens for Capacitive Touch Screen Tablets/Cell Phones (iPad, iPad Air, iPad Mini, iPhone, Kindle and All Android Devices)

- Mini Wireless Keyboard, Touchpad Mouse Combo with Backlit Multimedia Keys 2.4GHz USB Rechargeable Handheld Remote Control Keyboard for Smart TV, IPTV, PS4, PC, Pad (Black)

Cost before tax: $653.91