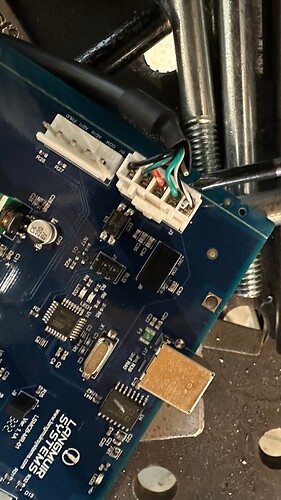

Can one of you that has replaced the module in there MR1 help me to figure out if this wire is broken or does it need to be there or even if it is important.

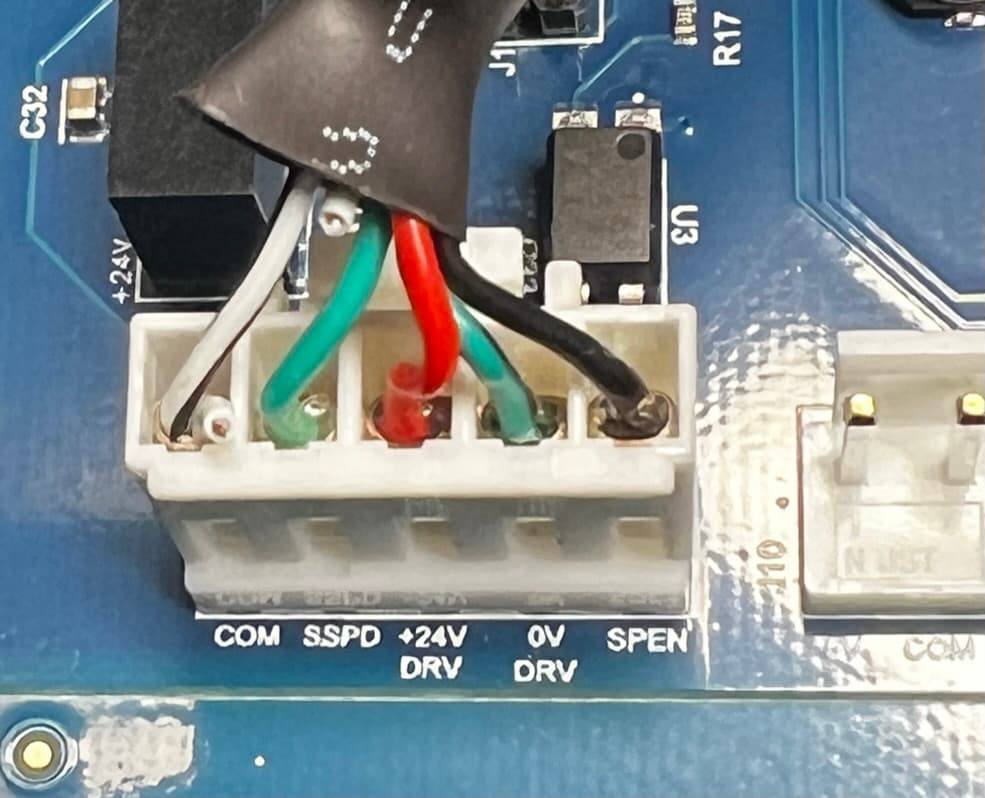

If you zoom in a bit you can see the ends of the wires. It does not appear cut or even stressed but the other wires were folded up like they were long and this wire was way to short during assy and it has finally let go. Maybe it is supposed to be this way I am just not sure?? I put a screwdriver on the wire part and you can see the very last pin on J3 has 2 wires with the one going no where??

That’s how they ship it. I assume they made a running change in the design and had to clip this wire on harnesses already made. You’re fine.

Excellent. Thank you Alex for clarifying. Just out of curiosity how did you know that??

It’s identical on mine. I also own a MR-1 and mapped out where all of the wires went when I was replacing my controls with LinuxCNC. I spent a while poking around at the stock spindle control wires (which is what that plug controls) before making my own cable for my new control board.

Can I make the assumption that I have to re-calibrate all my motor tuning or are those numbers saved in cut-control somehow?

I never used any motor tuning features in CutControl, so I’m not sure. I would guess that those settings are stored on your PC and not on the control card, but I don’t really know.

I might have used the wrong term, its called Travel Compensation #23 in the assy procedures.

Sorry, since Langmuir doesn’t share the source code or document their software very well I can’t guess if those parameters are stored on the PC or on the control card. I barely used Cut Control.

No worries. Thanks again for the help. You should look at a part time support job for Langmuir:)