Others are way more knowledgeable than I am on this topic without question. But that looks like a pretty good all around solution. Much better than how I first started. The only thing I might add, which I personally just implemented yesterday is an air to air cooler (condenser coil) at my air compressor to between head and tank. I am grabbing a ton of water before it even makes it into my system. This I believe would greatly extend the working time of your desiccant beads between changes.

Maybe post a link to that drier if you can

Will you post your implementation?

I have been running this desiccant dryer for almost 2 years and it works great. It was the least expensive quart sized desiccant dryer that I could find. Tru-Flate 56-081 Dessicant Dryer https://a.co/d/h6rGDdk

I tapped the holes in the top and made a bracket to attach it to the wall.

I use this in addition to a transmission cooler between the compressor and tank. ( This removes a lot of water). The air goes from the tank to a coalescing oil separator, the desiccant dryer and a Motor guard filter before going to the cutter.

I usually dry the desiccant breads in the oven every two weeks.

I am uploading the video currently @TomWS . as soon as its done I will post a link here with a couple of pictures.

@TomWS Here you go! Its not the prettiest, but it was done budget friendly and is effective. My two highest motivators!! lol My DIY air to air cooler for my compressor.

The environmental details are in the video description.

The natural gas flex hoses are a nice touch.

Thanks, cheaper than a roll of copper that I would probably crimp and crease anyways…lol.

What is the pressure rating on those hoses, usually they’re used on the low pressure side of the gas regulator.

@DnKFab Nice addition. Can you list the adapters you needed? (1/2NPT - 8-AN?)

250 psi is the test pressure of those natural gas flexes.

Normally we are running a few inches of water column in pressure.

Myself I almost never use the flex connectors with natural gas .I am old school and thread and turn black iron pipe for all my gas fitting. Normally just the kitchen range is on a long flexible whip so it can be pulled out and serviced.

great question @TomWS ! it appears that spec rating for their intended application is not higher than 5 psi. They are constructed of corrugated stainless steel. Im running 155psi…way outside of spec. I suspect the achilles heal of these are the compression fittings. the first few times i tested them i had leaks at the connections…the compression connections and the semi-swivel aspect of the ends. I may well blow out the line as i am substantially exceeding the pressure rating of the assembly. I never even considered their ratings would be so low. I am going to continue to use them as the compessor is outside and behind my shop. and i will just keep in mind those ratings. The only time they are pressurized is when the compressor is running and i will just not hang around when its actually running without some safety measures in mind. Thanks for pointing out that flaw in the setup!! with all that being said…Guys follow my example at your own risk and know that if you use this you are exceeding the ratings of these flex lines by a ton!!! I suggest you find another method to achieve the same goal with better suited materials!

ps. I did not keep track of the fittings because it is indeed a hodgpodge. of what i bought and what i had lying around. The fitting on my compressor head is a real oddball. Its from harbor freight. I imagine a good hose place or possibly automotive place could hook you up.

Here is one of those flex cables on Amazon.

“the design has been tested on strength and it can withstand an internal hydrostatic pressure of 250 psi or 17 mpa without bursting or showing signs of leaks.”

looks like a good replacement for mine in the future! thanks @TinWhisperer

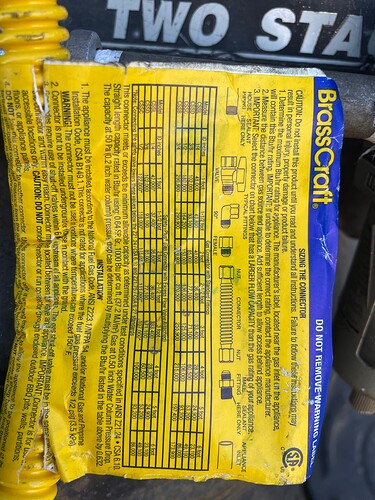

@TinWhisperer here is a pic of part of the label on the line I’m using. Is there anything useful you can discern from it?

Well that’s showing its BTU rating and showing its operating pressure.

I’ll see if I can find the actual test spec sheet that shows the pressure that it’s tested at which way exceeds anything that they would operate with in natural gas

I think im going to build one out of 1/2in copper pipe

you can build one out of copper or PEX…in fact PEX will dissipate the heat faster than copper…strange but true…

Are you serious? Man, I wish I had checked up on that. Pex is much easier in my opinion. But, I already have all my copper cut to size and just haven’t soldered it yet.

Insert Homer Simpson meme here: Doh!