It is interesting to note the bare PEX pipe actually has more heat loss than the bare copper pipe. The PEX has a heat loss of 31.96 Btuh/ft versus 29.634 Btuh/ft for the copper . Pipes with different wall thicknesses will have different amounts of energy loss.

I have a hard time believing that any plastic has a higher thermal conductivity than copper, which is the gold standard for heat sinks and cpu coolers.

After googling it I’m finding lots of conflicting info, mostly depending on what agenda the site is championing. Some Radiant heat sites saying that pex has a thermal conductivity rating of ~32 btuh/sqft vs coppers ~29 btuh/sqft while plumbing sites list the thermal rating of pex at 3.2btuh/sqft and saying it’ll save you money on hot water… I guess both claims are true since I read them on the internet.

Fascinating information. I sure wish I had known that as well I cloud have just run all my lines in Pex with liquid drops!! Which I eventually plan to do…but sounds like I could have killed two birds with one stone if I had done that first! I love the knowledge changed in this forum!

FWIW, Heat Loss and Thermal Conductivity are two different things. While I don’t know about PEX vs Cu heat loss, I do recognize the difference between the two, having worked with various electronic heat sinks on the past. Heat loss relies on some conductivity, obviously, but it’s about the ability to give up that heat to the surrounding space and may not be a function of conductivity. Having used PEX for radiant floors, I was surprised at its efficiency.

Comparing radiant flooring to an after-cooler is an apples to oranges situation. In a radiant floor application, it being a closed loop, any heat not transferred to the floor on the first pass through goes back into the system to be recirculated so lesser heat transfer capability is not as big of an issue (and in fact slower heat transfer would probably be a good thing since you wouldn’t be dumping all of your heat in the beginning of a loop) . Whereas an after-cooler only has one shot at getting out the maximum amount of heat as possible (and by consequence wringing as much moisture out as possible) before it makes it to your cutter.

With the inconclusive info I was able to find, I think I’ll stick to the tried and true myself. However, if anyone does try it I for one would be interested in the results, I very well could be wrong.

the difference is so small…

PEX is susceptible to UV light deterioration. That could be an issue if this is outside and exposed to sunlight. I doubt the UV from actual light fixtures would be much of an issue.

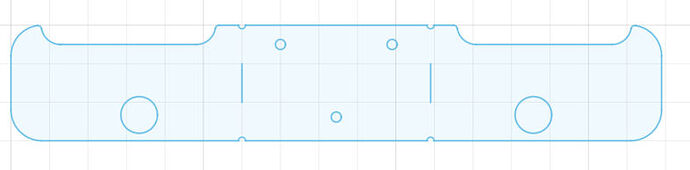

I ordered that Desiccant Dryer and finally got around to making a bracket for it. The metal I used was 12 gauge. I thought I might as well allow it to be used as a hanger for hose or what-not. I would be happy to share the file if anyone is interested.

Edit: I did put it on FireShare: Tru-Flate 56-081 Desicant Dryer Bracket | FireShare | Langmuir Systems