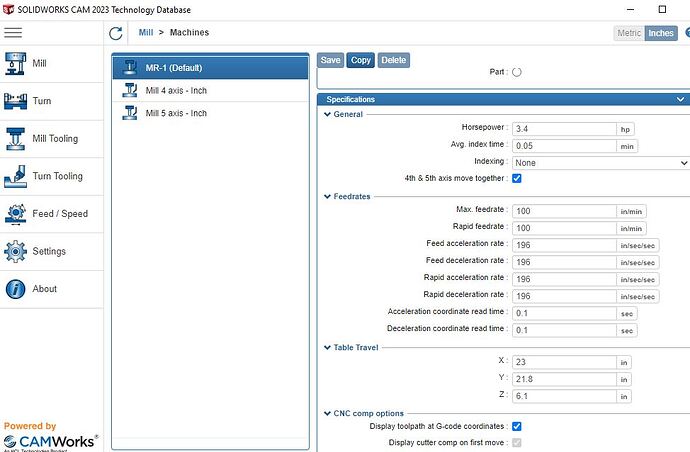

New to CNC mills and work in solidworks. Do the settings in solidworks technology database in the mill setup matter or does the post processor just overide and speed settings etc?

Haven’t gotten the mill yet just trying to setup best i can to learn how everything interacts while I wait.

I’ve been waiting patiently to see if anyone would respond to your question. It’s something I’ve been wondering too cause I’m going to have to cross this bridge fairly soon. I’ll let you know how I make out when I do.

I got my mill last week and am learning fairly quickly that every setting in solidworks CAM matters for setting up the rate at which it drives (IPM) because you have to define the material SFM in technology database as well as the depth of the cuts per mill operation that you create in the operation tree . You need to know the IPT or chip load for each type of coating end mill (manufacturers give charts) so that you don’t drive too fast and snap the bit. Once you define the sfm range for the material you use and the bit feeds and speeds though the solidworks Cam will show the in/min feed rate like the langmuir cut control displays and gives a pretty good estimate of time. I just ran my first program which was 35 minutes using an 1/8 inch endmill 4 flutes because they are some of the cheaper endmills and they would snap easy if I messed up my toolpath. But using a .002 chip load it did not break ! I was happy with the results of my test.

3 Likes

I’m happy to hear the SW technology database works like that. I’m kinda impressed at the built in tools SW has for making your own post. Seems more friendly than the HSMworks (Autodesk) plug-in we use at the moment.

Thanks for the update!